easyToolholder: Easy and Individual Toolholder Configuration

New Digital Tool from SCHUNK – the easyToolholder Configurator

October 17, 2023

New digital tool from SCHUNK – the easyToolholder configurator. This can be used for optimal online adaptation of standard toolholders to their respective machining task. The customized inquiry and ordering process takes place 24/7 in real time with full transparency.

The family of SCHUNK products that can be configured online is growing. In addition to grippers, gripper fingers and chuck jaws, with easyToolholder, a planning tool for customized toolholders is now available from SCHUNK, too. Instead of cost-intensive special solutions, standard hydraulic expansion toolholders can be customized with just a few clicks. The tool will also be extended to other toolholder technologies in the near future.

Technical clarification in real time – and configurable 24/7

With the easyToolholder product configurator, users from all sectors – for example, from the metalworking industry and from companies in the plastics and woodworking industries – have a useful digital tool that opens up new possibilities for customization. It makes application-specific solutions a reality in no time – around the clock, on all days and without the user having to log in via the website first.

In just a few clicks and by entering various parameters, a clamping device that is suited to your application can be designed from the broad portfolio of standard toolholders from the technology leader in toolholding and workholding, gripping technology and automation technology. This is conceived flexibly and very simply: First, you enter the machine interface and the clamping diameter for a wide variety of clamping tasks. The dimension for the length of the toolholder can also be adjusted. Broad options such as a data carrier chip or peripheral cooling can be added to adapt the toolholder optimally to its specific application.

Users receive a direct, captive and unmistakable assignment of tool and process data thanks to SCHUNK’s license-free, browser-based web tool. Finally, easyToolholder transmits the configuration in real time to the connected web store. Various download formats as well as all common CAD data formats are available here and can be used for virtual process simulation, or for collision analysis in CNC programming. Users also have the price and delivery time of the configured module calculated directly and transparently before their eyes.

More Information

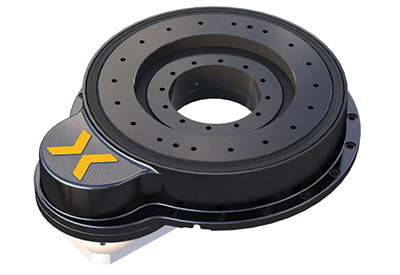

Related Product

New VERO-S AFS3 IOL Sensor from SCHUNK Detects Three Clamping States

The versatile SCHUNK VERO-S modular system enables workpieces and clamping devices to be mounted, positioned and clamped in no time at all. With its new VERO-S AFS3 IOL monitoring sensor, reliable information is provided on the clamping states of the modules.