Cosen Saws to Showcase Innovative Sawing Solutions at EASTEC 2023

Cosen Saws is excited to be exhibiting its latest band saw machines to a wide audience of manufacturing professionals at EASTEC 2023

March 24, 2023

Cosen Saws is one of the world’s leading band saw manufacturers with a diverse product line and a sales and service network covering all of North America. Cosen is proud to announce its participation in EASTEC 2023, the premier manufacturing trade show in the Northeast. The show will take place from May 16th – 18th, 2023 at the Eastern States Exposition in West Springfield, Massachusetts and Cosen Saws will be located at Booth 2114.

EASTEC 2023 provides an excellent opportunity for Cosen Saws to showcase its technologies and products to a wide variety of industry professionals covering many different applications. Cosen Saws will be exhibiting their latest band saw machines that focus on reliability. Visitors will be able to see live demonstrations Cosen’s cutting edge equipment and learn about all of Cosen saws cutting solutions for improving manufacturing efficiency and productivity.

Use Cosen Saws EASTEC page to register for free

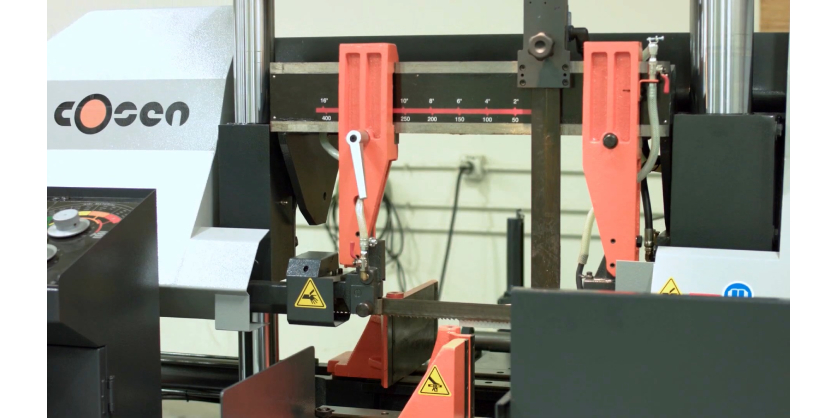

Cosen Saws will be showcasing the following band saws at Booth 2114:

MH-1018JA – Manual Horizontal Scissor Style Band Saw

Capacity: 9″ x 16.5″

The MH-1018JA is a new update on the foundational machine that has been manufactured by Cosen for over thirty years. For the shop that has a variety of multiple users and needs to cut a variety of structural or solid materials, it is the perfect manual machine. Its solid construction ensures many years of reliability and a high level of accuracy.

C-260NC – Fully Automatic, Horizontal Scissor Style Band Saw

Capacity: 10.2″ x 11.8″

The C-260NC provides every automatic feature needed in a scissor style band saw. It is very suitable for high production settings just like other Cosen automatic machines. The control system allows you to store 100 jobs and index up to 999″. The C-260NC can help maximize your workflow efficiency due to its advanced capabilities and reliability.

SH-500M – Semi-Automatic Horizontal Scissor Style, Mitering Band Saw

Capacity: 11″ x 19.7″

The SH-500M is the most popular semi-automatic machine offered by Cosen. This machine can miter cut up to 60°. Whether cutting single or multiple pieces, this saw is able to meet the diverse needs of any job shop with its relatively small footprint. It has a large capacity and is easy to use making it perfect for a variety of materials and any operator.

V-1822 – Manual Vertical Tilt-Frame Band Saw

Capacity: 18″ x 22″

In an ever changing and growing fabrication market, the need for cost effective cutting solutions at different capacities and price points is evident. With the growing popularity of vertical saw design, Cosen’s V-1822 takes the renown tilt frame-design and applies to a reliably constructed yet small footprint. The manual saw design allows you to control the cutting angle up to 60° both ways.

Cosen Saws is excited to share all of these band saws at EASTEC 2023. EASTEC provides an opportunity for Cosen to connect with the many manufacturing professionals and demonstrate our commitment to helping advance the industry.

More Information

Related Product

Cosen Saws’ automatic dual column saws provide many advantages that increase efficiency

Cosen Saws, a leading manufacturer of industrial sawing equipment offers a variety of automatic dual columns band saws with round capacities ranging from 12″ to 40″. Cosen Saws automatic dual column band saws are designed to meet the demands of modern manufacturing, service centers, and the fabrication industries.