What Is Regenerative Braking?

December 9, 2025

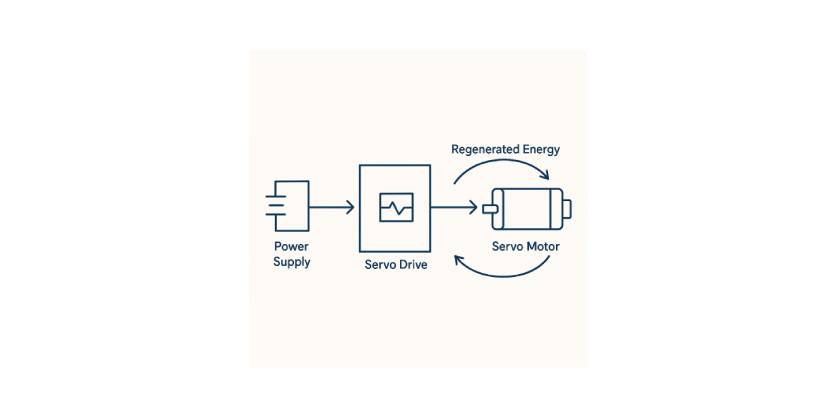

Regenerative braking is a system that converts kinetic energy – normally lost as heat during braking – into electrical energy that can be stored or reused.

Instead of using friction brakes to dissipate energy, the motor functions as a generator during deceleration, reversing the flow of current. The rotational energy from the load or vehicle drives the motor, which in turn produces electricity.

In mechatronic and motion control systems, regenerative braking appears in servomotors, stepper drives, and electric vehicle powertrains.

It improves efficiency, reduces wear on mechanical brakes, and allows energy recovery for reuse.

Four-Quadrant Motor Operation

Electric drives operate within four quadrants of the torque-speed plane, defined by the direction of torque and rotation:

| Quadrant | Speed Direction | Torque Direction | Mode of Operation | Energy Flow |

|---|---|---|---|---|

| I | Forward | Forward | Forward Motoring | Electrical → Mechanical |

| II | Forward | Reverse | Forward Regeneration | Mechanical → Electrical |

| III | Reverse | Reverse | Reverse Motoring | Electrical → Mechanical |

| IV | Reverse | Forward | Reverse Regeneration | Mechanical → Electrical |

Quadrants I and III represent motoring conditions, where electrical power from the drive produces mechanical output.

Quadrants II and IV represent regenerative operation, where the motor behaves as a generator, converting mechanical energy from the load into electrical energy.

During regenerative braking, the drive transitions from Quadrant I to II (or III to IV for reverse motion). The generated energy raises the DC bus voltage, requiring management through resistors, energy recovery circuits, or shared DC bus configurations as outlined below.

How Regenerative Braking Works

- Normal Operation – The motor draws current from the power source to generate torque and motion.

- Braking Phase – When a commanded deceleration occurs, the drive switches from motoring to generating mode.

- Energy Conversion – The kinetic energy of the moving mass is converted to electrical energy as the motor acts as a generator.

- Energy Return – The generated energy is directed back into the drive’s DC bus, where it raises the bus voltage.

- Energy Management – The excess voltage must be safely handled—either stored or dissipated—to maintain system stability.

Energy Management Options

Dynamic Braking Resistor

The most common method for handling regenerated energy in servo and motion systems. When bus voltage exceeds a threshold, the drive diverts energy to an external resistor, where it’s converted into heat. Simple and reliable but inefficient since the energy is not reused. Typically used in single-axis systems or where energy storage isn’t practical.

Key design considerations:

- Proper resistor wattage and resistance value.

- Adequate heat dissipation and spacing.

- Drive must support braking chopper control or external braking module.

Regenerative Power Supply (Active Front End)

Used in multi-axis or high-power systems where recovered energy can be reused. Instead of burning off the energy, the drive or AFE (Active Front End) inverts it back onto the AC line for use by other equipment. Improves energy efficiency and reduces facility power consumption. Requires drives with bidirectional power capability.

Advantages:

- Reduces heat buildup and HVAC load.

- Provides smooth line current and improved power factor.

- Ideal for applications with frequent acceleration/deceleration cycles (e.g., elevators, CNCs, conveyors).

Shared DC Bus Systems

Multiple servo drives share a common DC bus. Drives that are braking feed energy into the bus, while drives that are motoring draw from it. Reduces total system energy use and peak current draw from the AC line. Often combined with a small braking resistor or capacitor bank to stabilize the system.

Typical in:

- Multi-axis robotic cells

- Coordinated motion platforms

- Packaging lines with asynchronous motor demands

Energy Storage (Capacitors or Batteries)

Instead of dissipating energy, it can be temporarily stored for reuse. Supercapacitors can absorb short bursts of regenerative energy and supply it back during acceleration. Batteries can be used for longer-term storage, as in electric vehicles or mobile robots.

Challenges:

- Requires charge management circuitry.

- Battery lifespan is affected by frequent charge/discharge cycles.

- Not ideal for every industrial environment due to safety and maintenance.

System-Level Design Considerations

- Drive Capabilities: Verify if the servo or inverter supports regenerative operation or only passive braking.

- DC Bus Monitoring: Overvoltage protection is critical; drives must detect and manage excess energy.

- Thermal Management: If using resistors, ensure adequate cooling and physical separation from sensitive components.

- Safety: Include discharge circuits and isolation features to prevent hazardous voltages after power-down.

- Power Quality: Active regeneration systems must comply with harmonic and EMC standards.

Typical Industrial Use Cases

- Elevators & Lifts: Energy from descent reused for ascent.

- CNC Machines: Axes braking frequently during toolpath changes.

- Conveyors: Decelerating sections feeding energy to accelerating ones.

- Robotics: Multi-axis systems balancing regenerative loads.

- Electric Vehicles: Battery charging during or downhill motion.

Regenerative braking transforms kinetic energy into electrical energy instead of wasting it as heat. Managing this energy effectively depends on system design and operational needs. Options range from simple dynamic braking resistors to sophisticated regenerative front ends and shared DC bus architectures. Efficient handling of regenerated power can yield significant energy savings, reduced thermal load, and extended equipment lifespan.

Related Story

Tariff-Free Automation Products in Canada from Electromate

Electromate understands how recent tariff policies have impacted the cost and availability of automation products and components across North America. That is why the have made it easier for Canadian manufacturers, OEMs, and system integrators to source tariff-free mechatronic and robotic automation products and components.