OTI Lumionics Transforms OLED Testing with Next-Generation Lab Automation

June 11, 2025

Automated material testing system triples throughput and achieves highly precise control for nanometer-scale deposition with Beckhoff technology

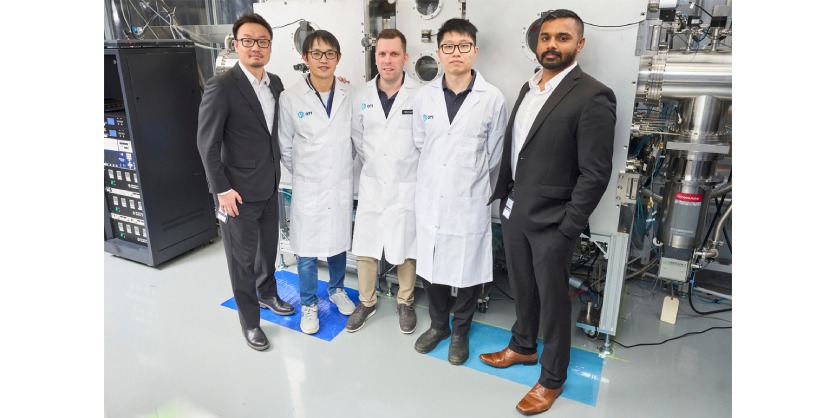

In the race to develop next-generation display technologies, one of the biggest challenges is creating and validating new materials that can meet increasingly demanding specifications. OTI Lumionics, an advanced materials innovation company located in Mississauga, Ontario, Canada, is tackling this challenge head-on by revolutionizing how high-end OLED materials are developed and tested.

“We’re developing breakthrough materials by design, using quantum simulations, machine learning, and real-world testing in pilot production,” said Michael Helander, CEO and President of OTI Lumionics

The company has leveraged an innovative automated testing system and facility to accelerate the development of materials that will enable breakthrough features in a range of electronics—from smartphones with under-display cameras to state-of-the-art automotive displays.

“Working closely with partners like Apple, Samsung, and LG, we’re creating the key enabling materials for next-generation OLED displays in consumer electronics and automotive applications,” Helander added.

Not the same old OLED testing

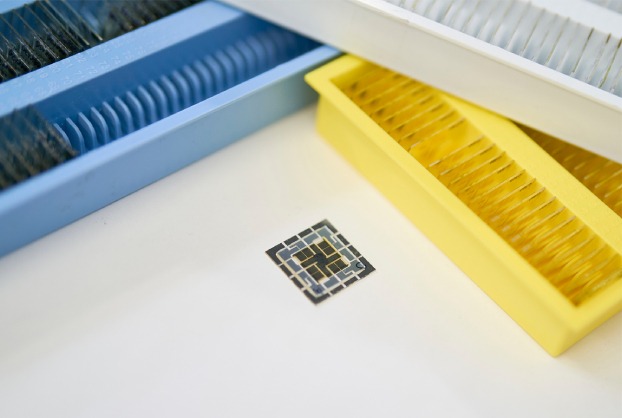

To develop an automated testing system that would enable this kind of success, OTI created EPOC-auto, their innovative material testing platform. Building this system required overcoming a complex set of challenges that pushed the boundaries of precision control and automation. The system needed to handle 20 substrates with completely different layer structures automatically while maintaining movement accuracy of 0.1 mm for substrate and mask alignment—a level of material deposition control that would be difficult even in a single operation, let alone sustained across continuous testing cycles

“Before developing EPOC-auto, we were struggling with different results from different operators,” said Terry Xu, VP Engineering at OTI Lumionics. “It was difficult to repeat the same OLED structure and thus to fine-tune some critical parameters. The tools were mostly idle because the device structure must be completed in one run during the day. As a result, the operating cost of these tools was very high, while the yield of working OLED samples was low.

Technical requirements were also very demanding, as the system needed to control multiple material sources simultaneously, each requiring its own precision controller for managing deposition rates at nanometer scale. To get consistent results, hundreds of sensors and moving elements had to work in perfect coordination. Adding to the complexity, the system also needed to adapt to changing experimental requirements.

“Because of the experimental nature of our business, our objectives can vary daily,” explained Terry Yang, Senior Mechatronics Engineer. “And this means we needed a system that could be adjusted and upgraded at a rapid pace.”

Illuminating innovation with Beckhoff and EtherCAT

To address these complex testing challenges, OTI made a strategic decision to standardize on Beckhoff automation technology as their control platform. At the heart of the solution is the CX2020 embedded PC, which manages the entire automated testing process while providing the precise, deterministic control needed for nanometer-scale material deposition. This is complemented by TwinCAT automation software for sophisticated process control and the real time EtherCAT industrial Ethernet system for seamless integration of control software, actuators, and scientific instruments.

“The flexibility and scalability of EtherCAT were big factors,” said Yang. “It’s the fastest industrial Ethernet communication protocol around, and Beckhoff offers a wide complement of hardware. It’s a turnkey package that streamlines process and system design, making it simple and efficient to complete a harmonized, consistent industrial solution at a high standard.”

The system architecture proved particularly valuable for integrating specialized scientific instruments with industrial automation components. EtherCAT terminals enabled communication with third-party devices while providing the precise control needed for multiple process parameters. This flexibility was crucial given the unique requirements of semiconductor research and development.

“The serial communication terminals from Beckhoff have been essential for integrating third-party components into our machines, while the scalability of the EtherCAT systems is perfect for our daily changing requirements and objectives,” Yang said.

Integrating scientific instruments with industrial automation

The success of OTI’s automated testing system hinged on seamlessly integrating specialized scientific instruments with standard industrial automation components. Beckhoff’s EtherCAT terminals proved crucial in this area, helping to bridge the gap between scientific instruments and automation while achieving precise control over the complex OLED fabrication process.

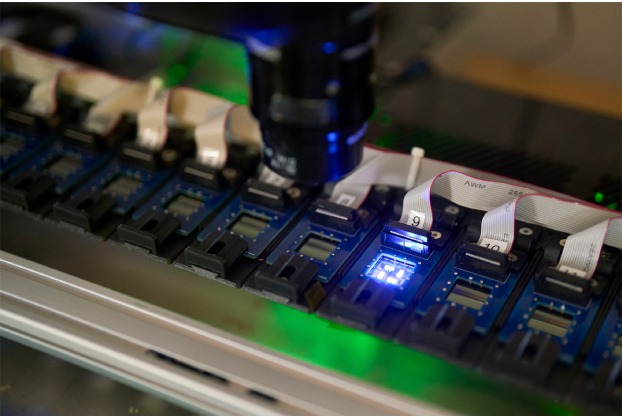

OTI leveraged EL6021 serial interface terminals, which provide RS422/RS485 communication at up to 115.2 kbaud, to enable high-speed data exchange with specialized equipment like quartz crystal microbalances and vacuum controllers. EL3024 4-channel analog input terminals, meanwhile, deliver 12-bit resolution with electrical isolation, providing accurate monitoring of multiple deposition parameters simultaneously while protecting sensitive measurement equipment.

The EL3318 8-channel thermocouple input terminals enable precise temperature monitoring across multiple thermal zones with built-in linearization and cold junction compensation.

This combination of terminals creates a robust measurement and control infrastructure that maintains accuracy down to the nanometer scale required for OLED material development. The terminals’ compact design and direct EtherCAT implementation throughout the system also simplify cabinet design while providing the flexibility to add new measurement points as testing requirements evolved.

Building on this streamlined architecture, the motion control system integrates AM8122 compact servomotors with EL7211-9014 EtherCAT terminals for precise positioning control.

“The One Cable Technology for the compact servomotors makes wiring clean, while the serial communication libraries allow easy integration of third-party components,” Yang explained. This simplified approach to integration provided the precision required for nanometer-scale material deposition while preserving the flexibility needed in an R&D environment. The EL7211-9014 terminals’ fast control technology, meanwhile, enables highly dynamic positioning tasks while providing comprehensive monitoring of system parameters.

OTI worked closely with Rui Zhang, P.Eng., Application Engineer & Drive Technology Products Specialist at Beckhoff Canada, who assisted with integrating the AM8122 compact servomotors and basic function block configuration. The system incorporates five AX5201 servo drives that, together with the motors, form the critical interface between the mechanical system and the control system.

These digital compact servo drives offer exceptional performance for highly dynamic positioning tasks with current control cycles as fast as 62.5 μs. The high-speed EtherCAT communication enables ideal interfacing with the PC-based control technology while maintaining precise synchronization between all system components.

OTI benefits from the flexible feedback interface of the AX5000 series, which supports connections with various feedback systems, including resolvers and high-resolution encoders. This flexibility, combined with the drives’ variable parameterization capabilities for current and speed filters allowed the engineering team to fine-tune the motion control for the nanometer-precision requirements of OLED material deposition.

“OTI’s strong technical foundation and experience with object-oriented programming principles made the integration process exceptionally smooth,” Zhang said. “Their engineering team quickly grasped the servo system configuration, allowing them to adapt the technology to their specific R&D requirements with minimal support.”

The system leverages TwinCAT automation software, which integrates real-time control with PLC, NC, and CNC functionality on a single platform. The software’s engineering environment enables configuration, programming, debugging, and diagnostics of all connected automation devices.

Using Structured Text programming within the TwinCAT engineering environment, OTI created a sophisticated yet maintainable control system.

“We exclusively use Structured Text because of its close resemblance to object-oriented programming,” noted Yang. “This makes our software easy to read and debug because of the concise programming style.”

From complexity to clarity: simplifying advanced testing

The impact of OTI’s automated testing system has been transformative in both efficiency and reliability.

“EPOC-auto can run 24/7 with minimal operator intervention,” Xu said, explaining that it has more than three times the throughput of a semi-automation or manual system. “So far, it has run one month nonstop without an error. Moreover, the testing repeatability is twice as good as our previous systems.”

Enhanced data collection and analysis capabilities have proven particularly valuable, with continuous recording of vacuum levels and temperature providing unprecedented insight into the testing process. While the complexities of materials science remain challenging, this combination of reliability and precision has accelerated OTI’s ability to develop and validate new materials, particularly for emerging applications like cathode patterning technology. As customer demands grow, the system’s flexibility will enable expansion into new capabilities, including sputtering, e-beam, and CVD processes.

“This automated testing platform has fundamentally changed how we innovate,” said Xu. “When you can triple your testing output while improving precision, you’re not just solving today’s challenges—you’re accelerating the future of display technology.”

More Information

Related Story

Beckhoff Nominated for Best of Industry Award 2024

Beckhoff is delighted to announce that they has been nominated for the Best of Industry Award 2024 in the Artificial Intelligence category. This prestigious award, presented by the Vogel Communications Group, honors outstanding innovations in the industry.

Their TwinCAT 3 Machine Learning Creator is one of the top 3 innovations in its category. Votes were open for 5 months, and over 20,000 votes were collected across 15 different categories. Beckhoff is proud to be among the finalists and would like to thank everyone who supported them by voting.