Building the Future of Smart Tool Manufacturing – Together

Why now Is the time to join the AIMS ecosystem

August 27, 2025

By Samuel Kirkpatrick, ANCA Senior Product Manager – AIMS

The manufacturing industry is undergoing its most transformative shift in over a century. As smart automation, AI-driven production systems, and advanced robotics redefine what’s possible, manufacturers are seeking ways to scale efficiently, adapt rapidly, and remain competitive in a world that rewards agility and intelligence.

In the tool and cutter grinding (TCG) sector, ANCA has been at the forefront of that transformation for 50 plus years. But the industry challenges ahead—labour shortages, productivity pressures, rising costs, and demand for traceability—require more than smart machines. They demand integrated, open, and collaborative systems that elevate the entire production ecosystem.

This is where AIMS—the ANCA Integrated Manufacturing System—enters the spotlight. Designed to Connect, Automate, Create, AIMS is an open, interoperable smart factory solution that is reshaping what’s possible in tool manufacturing.

And now, ANCA is inviting visionary technology equipment manufacturing, or TCG industry players to become partners in this growing global ecosystem.

Why Forward-Thinking Vendors Are Aligning with Open Ecosystems Like AIMS

As tool manufacturers navigate mounting cost pressures, evolving customer expectations, and widening skills gaps, there’s growing recognition that it’s partnerships that will meet the complex needs of a modern smart factory. The era of closed systems and proprietary silos is giving way to collaborative, open ecosystems that bring together complementary technologies to deliver holistic value.

Here’s why:

- Open ecosystems are shaping purchasing decisions

Manufacturers are no longer sourcing machines or software in isolation. They’re looking for integrated, interoperable systems that reduce complexity and risk. By being part of a trusted ecosystem like AIMS, vendors position themselves to be part of these full-stack solutions—rather than competing in fragmented Request for Proposals. - Value is shifting from products to solutions

It’s not just what a product does—it’s how it fits into a manufacturer’s process. AIMS partners gain the advantage of being embedded in a solution-oriented sales approach, where customer conversations focus on end-to-end value, not line-item pricing. - Reach and visibility multiply through shared infrastructure

The traditional sales model—one company, one channel—is being replaced by co-marketing, co-selling, and shared customer journeys. AIMS opens doors to ANCA’s global customer base, sales team, and service network—creating scale many vendors can’t access alone. - Integration is the new differentiator

The ability to seamlessly connect to a customer’s digital factory infrastructure is fast becoming a purchasing prerequisite. AIMS provides both the technical infrastructure and engineering collaboration to make third-party integration straightforward, turning “partnership potential” into real-world deployments. - Collaborative innovation unlocks new customer value

In a modular factory environment, the best innovation doesn’t always come from one place. Smart vendors know that collaborating—whether on data sharing, software features, or joint R&D—can unlock use cases neither party could deliver alone. AIMS provides the platform for that collaboration to thrive.

That’s why technology vendors across hardware, software, and automation are increasingly seeking partnerships that allow them to embed their innovation into broader platforms – like ANCA’s AIMS. Becoming part of the AIMS-ready ecosystem offers a powerful position in an industry-leading platform.

The AIMS ecosystem is leading the industry and at the forefront of smart manufacturing as the benchmark for integrated, end-to-end tool production with world leading closed loop geometry compensation.

Beyond access to ANCA’s large and loyal global customer base, AIMS partners benefit from two-way opportunity sharing, preferred inclusion in end-to-end customer solutions, and potential access to ANCA’s international sales and service networks.

With detailed integration support and co-marketing opportunities, partners can scale faster, extend their reach, and deliver greater value by being part of a collaborative, future-ready ecosystem built on openness, interoperability, and shared innovation.

Who Could—and Should—Partner?

The AIMS ecosystem welcomes any organisation that can add value to the smart factory experience for tool manufacturers. This includes:

- Tool measurement and metrology equipment providers

(e.g. ZOLLER, a current AIMS partner) - Machine accessory and fixture manufacturers

(e.g. Arobotech-style component manufacturers) - Tool and cutter industry machinery providers

(edge prep, laser marking, packaging, cut & chamfering, etc.) - Smart manufacturing software companies

(MES, ERP, simulation, production monitoring) - Worker tracking, localisation, and wearable tech providers

- AR and operator augmentation companies

- Barcode scanning and digital interface hardware suppliers

But most importantly: if your solution improves automation, integration, traceability, or productivity in a factory—there’s a place for you in AIMS.

Why AIMS, Why Now?

Tool manufacturers are under increasing pressure to do more with less. AIMS addresses that challenge by connecting every process and piece of equipment into a single, intelligent, modular system. Whether it’s integrating a third-party machine without a native data interface, or scaling up to fully autonomous, lights-out manufacturing—AIMS makes it possible.

For customers, the benefits are clear:

- Up to 30% higher machine utilisation

- Up to 20% reduction in production costs

- Enhanced traceability, quality assurance, and error reduction

- Real-time data at operator and plant manager level

- Compatibility with both legacy and next-gen equipment

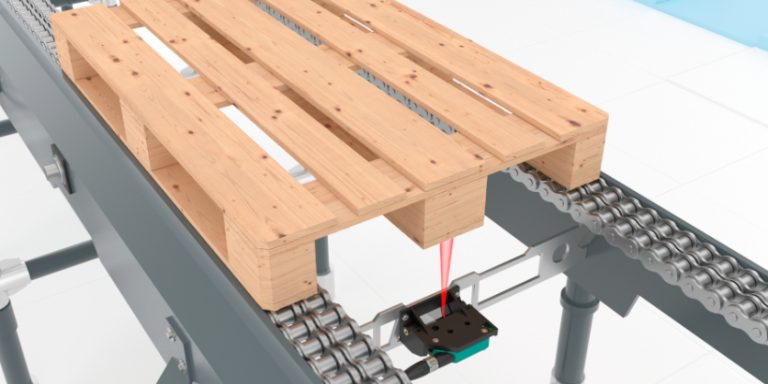

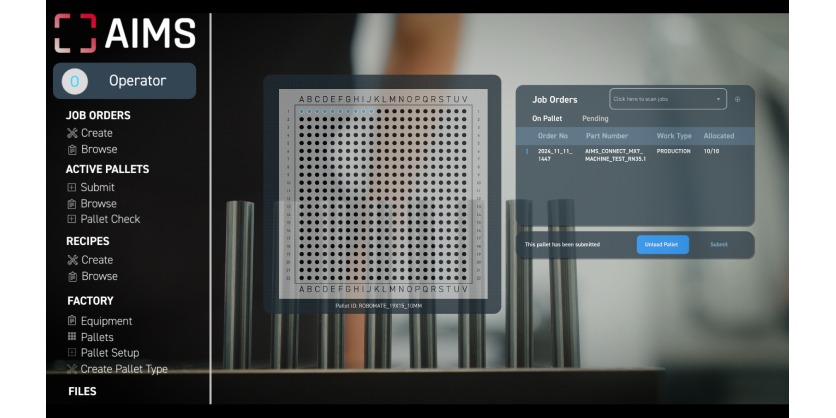

At the core of AIMS, is the AIMS Server which orchestrates workflows, connectivity, and compliance across grinding, measurement, laser marking, and IT systems (including ERP/MES) through scalable features like worker guidance with AIMS Connect to fully autonomous workflows with AIMS Automate.

Key components such as AutoFetch (an autonomous mobile robot) and AutoComp (the world-leading closed-loop tool geometry measurement and compensation system) provide seamless tool handling and tolerance control, drastically reducing scrap and manual intervention.

This flexible architecture allows manufacturers to start with worker guidance and job management and then scale up to fully autonomous, end-to-end production cells—all while gaining real-time data insights for better decision-making and higher machine utilisation.

As ANCA cements its transition from capital equipment manufacturer to a true Industry 4.0 solutions provider and technology partner, AIMS is the spearhead of that transformation.

AIMS represents an evolution—one that started in 1974 with CNC automation, progressed to robotic tending in the 1990s, and now culminates in a flexible, smart, autonomous factory standard.

Building the Future-Together

Becoming an AIMS-ready partner means more than integrating technology—it’s about shaping the future of manufacturing. For partners, it’s an opportunity to embed innovation into a globally trusted ecosystem, accelerate market access, and collaborate on smarter, more complete solutions. For AIMS customers, it unlocks greater flexibility, faster innovation, and a seamlessly connected production environment—powered by best-in-class technologies working in harmony.

As manufacturing moves toward modular, autonomous, and data-driven operations, the value of open, integrated ecosystems is undeniable. Together, we can raise industry standards, accelerate digital transformation, and deliver the intelligent, adaptive factories of tomorrow.

Related Story

ANCA’s AIMS Selected as Finalist for 2024 Manufacturing Leadership Council Awards

The Manufacturing Leadership Council (MLC) is the digital transformation division of the National Association of Manufacturers and, as part of its mission, annually seeks world-class manufacturing companies and key individuals who contribute to the technology. 2024 marks the 20th anniversary of this premier awards program.

On June 5, 2024, various companies and individuals who have made significant contributions to the digital manufacturing transformation in America will be recognized and winners named throughout 9 categories. Among the finalists for the prestigious Engineering and Production Technology award is the ANCA Integrated Manufacturing System (AIMS), a recently developed, fully automated grinding, gauging and materials handling system with workflow monitoring, full tracking and data management capability. It allows shops and production departments to achieve a lights-out manufacturing ecosystem in coordination with company control protocols. ANCA is an acknowledged global leader in this technology.