Pilz – Production’s Rolling!

November 9, 2021

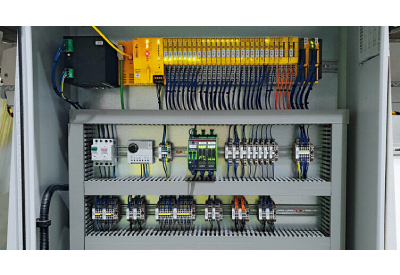

When exchanging paper reels weighing hundreds of kilos to produce corrugated boards at Austrian cardboard packaging manufacturer Mosburger GmbH, the risk potential for the operator was high because the process requires manual intervention. To reduce this risk to a minimum, Mosburger relies on a comprehensive safety solution comprising the automation system PSS 4000 and the safety gate switch PSENcode.

From the storeroom, several tonnes of paper reels travel across the production plant’s operating area because, due to lack of space, the plant is built “back to front”. That’s why each reel must be inserted manually by an operator, with a considerable loss of efficiency. Also, for reasons of infrastructure, the plant had been reset from automatic to manual mode. A practicable – in other words tamper-proof – complete automation solution should make the plant productive again, while at the same time ensuring safety for the operator. Mosburger was convinced by the complete package comprising software tools, diagnostic and visualisation systems and automation solutions ranging from sensor and control technology through to actuator technology. Today, the automation system PSS 4000 is at the heart of the solution, working in conjunction with the coded safety switches PSENcode to provide automated safety. Streamlined workflows and short downtimes are another feature.

Benefits at a glance:

- Increased productivity: shorter cycles when changing reels due to the safe, complete solution with PSS 4000

- Low investment costs, recouped within three years thanks to shorter downtimes

- Tamper-proof solution: comprehensive, practicable safety concept ensures safer workflows

For applications of the PSS 4000, click here, and for applications for PSENcode click here