Omron’s Traceability 4.0

October 31, 2024

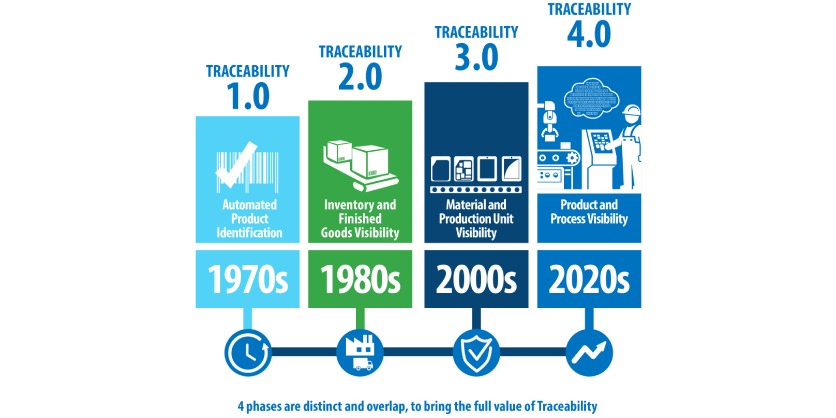

The need to control and have visibility in the automation processes has increased. Omron’s traceability 4.0 connects digital and physical technology to optimize and improve yield. They add additional value with quality components and products. Traceability 4.0 connects information about people, processes, equipment, and parts.

More Information

Related Story

Traceability 4.0. How Omron Can Help You Get More Out of Your Digital Transformation

Traceability is important for many reasons. Without it, it would be virtually impossible to mitigate quality issues in the field. Many industries require tracking and trace for components and assemblies such as automotive, life sciences, food and beverage. These industries require that manufacturers record and store data for every component or batch that is used to complete the finished good in the event of a future recall or quality issue.

Traceability is necessary to verify that proper materials, quality, testing, and assembly have been completed. It helps maintain brand loyalty via customer transparency, and it provides information about product quality and supply chain. Traceability can provide a staggering number of data points, and it can be challenging to know how to best make use of this information.

Today, more industries are starting to adapt these same track and trace processes, not necessarily to protect themselves in the event of a recall or issue, but because they recognize the advantages the data from traceability can provide. They see the potential for using this data in a proactive way.