Experience Automation Knowledge at SHUNK’s 8th CoLab in Hertogenbosch

Match 9, 2023

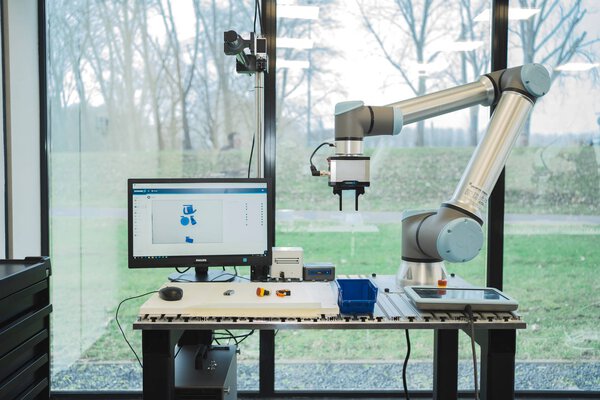

On February 9, 2023, SCHUNK opened its eighth CoLab worldwide. The new robot application center is located at the Dutch site in ‘s-Hertogenbosch. Here, experts accompany the way into automated processes and test customer-specific automation modules realistically on different lightweight robots.

Automation is no longer a trend, but a necessary means of keeping pace. Customers of SCHUNK Intec Netherlands can now test automation applications in the new CoLab, and exchange ideas with SCHUNK experts. In this way, they can find the optimal solution for their own production and minimize their investment risk. Robots from the renowned suppliers FANUC, TechMan, and Universal Robots are available for this purpose on a 75 square meter surface. Of course, the lab’s equipment also includes the latest innovative SCHUNK technologies, for example the intelligent 2D Grasping Kit for handling unsorted parts or the smart iTendo² toolholder for transparent machining processes, as well as a 3D printer, so that gripper fingers can be produced on site.

At the opening, in the beginning of February, General Manager, Guido Segers, explained the advantages of this approach to the 50 guests present:

“The CoLab offers customers the opportunity to develop, test and validate their application together with specialists. And this validation is an important advantage, because it accelerates commissioning at the customer’s site.”

Expert knowledge at the CoLab

SCHUNK customers gain practical knowledge in automation. “Our CoLab is a kind of knowledge center for the entire manufacturing industry. We share this knowledge here,” emphasizes Segers. SCHUNK shares its expertise in partnership, as do experienced robot and sensor suppliers. A grinding belt manufacturer and a milling cutter and drilling supplier are also available for application testing. Live demos and workshops serve as a platform for exchange for all participants.

The CoLab in ‘s-Hertogenbosch already benefits from the experience of seven application centers that SCHUNK has opened worldwide since 2020. The low-threshold concept of trying out different gripping techniques with different robots in a realistic production environment has quickly caught on – with customers and partners, but also in the training of future specialists. For example, the CoLab of SCHUNK Intec Sweden deliberately involves educational institutions.

Another Automation article, “Electrozad Automation Event Showcases Latest Industry Advancements” from Mechatronics Canada

Source Available Here