Rethink Robotics Debuts Seven New Cobots at IMTS 2024

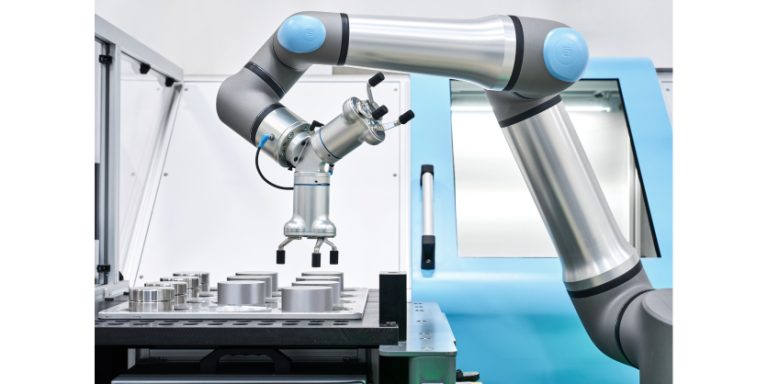

September 9, 2024 The Rethink Reacher cobot line handles payloads from 7 to 30 kg. Rethink Robotics returns to the market at IMTS, where it unveils its Rethink Reacher (RE) line of collaborative robots (cobots). With a long history as a pioneer in advanced technologies and a partner for the industry when it comes to…