Beckhoff Future-Proofs Hybrid Connectors in Industrial Cable Offering

December 9, 2024

The comprehensive hybrid connector portfolio from Beckhoff is ready for upcoming IEC 61076-2-118 standard updates, further enhancing EtherCAT-based One Cable Automation technology

Beckhoff’s proven hybrid connectors, part of the company’s One Cable Automation (OCA) solution, are receiving a major update to better support distributed automation well into the future. Beyond the design advantages of consistent modularization with a uniform data core, these connectors now comply with the upcoming IEC 61076-2-118 standard, enabling a seamless transition in advance of the rollout.

Roughly 100,000 OCA connectors from Beckhoff have already been proven in the field, predominantly in EtherCAT applications. Now, Beckhoff hybrid connectors are among the first products to comply with the IEC 61076-2-118 standard, which should be published by the end of 2024. Early adoption of this standard safeguards users in two key ways:

- strengthening supply chains and second-source strategies to ensure availability

- maximizing long-term reliability through established and widely adopted standards

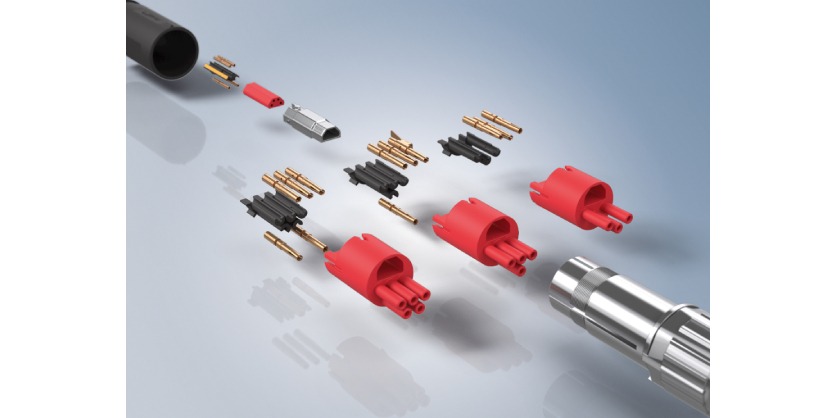

Hybrid connectors transmit power and data via a single line to reduce cable and connector expense, not to mention assembly time and cost. The OCA solution, which Beckhoff developed with a partner, offers the additional advantage of high modularity, permitting a wide range of cable and connector variants for numerous applications while providing mechanical coding to minimize connection errors.

The uniform data module remains standard in all four sizes: B12, B17, B23, and B40. This modularity greatly simplifies installation rather than creating additional work. In addition, the clear color markings on the contact carrier match the wire color of the cable, which eliminates outdated requirements for complex documentation that details each individual pin assignment.

Beckhoff’s streamlined hybrid connector portfolio comprises just 10 individual components – significantly fewer than comparable third-party products. The intuitive process prevents incorrect assemblony by design because the individual parts can only be assembled in one direction. In combination with the data module, this typically reduces assembly time by two-thirds.

More Information

Related Story

ASI8100 Stepper Motors with Integrated Drives Enable Cabinet-Free Machine Concepts

The ASI8100 stepper motor with built-in drive from Beckhoff adds another space-saving tool to the company’s broad range of compact drive technology products (up to 48 V DC). The ASI8100 series combines a stepper motor, stepper motor output stage, and fieldbus connection in a fully integrated design. These EtherCAT devices mount directly on the machine without a control cabinet or upstream I/O, allowing for highly compact, control cabinet-free machines.