New igus Smart Fixed Flange Bearings Unlock Predictive Maintenance

January 17, 2024

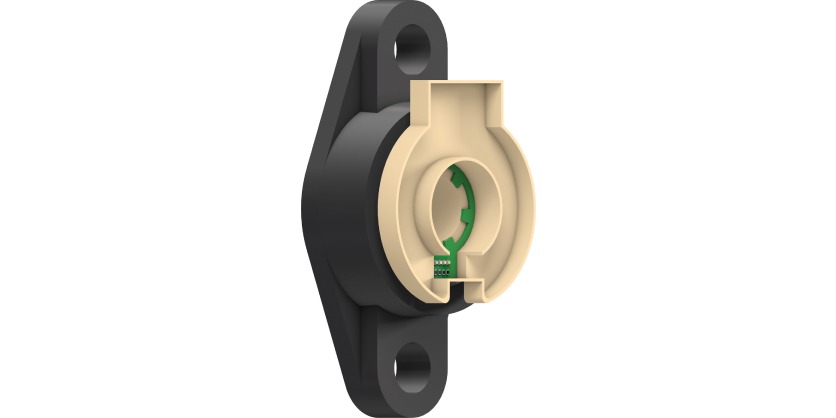

Intelligent two- and four-hole fixed flange bearings with wireless sensing capabilities for wear detection

igus®, a global manufacturer of motion plastics, has developed intelligent two- and four-hole fixed flange bearings with wireless sensing capabilities for wear detection, enabling condition monitoring and preventing costly machine breakdowns.

Constructed from self-lubricating, high-performance plastic, the bearings feature an integrated abrasion sensor, thin circuit board and cableless battery supply. Wear interrupts the board’s conductor paths, causing the electronics lose the signal. The sensor then transmits a long-range network signal to an igus i.Cee switch cabinet module for analysis, including the percentage of abrasion. Over time, the sensor wears away layer by layer — parallel to the bearing’s running surface — and will continue to transmit signals on the bearing’s condition. Users can see the remaining service life and maintenance requirements via a web-based dashboard, which they can access from a PC, tablet or smartphone.

Previously, worn fixed flange bearings would have been easy to overlook, leading to expensive system failure. “This scenario is no longer science fiction,” says Thomas Preissner, Head of Business Unit, igubal® Spherical Bearings, at igus. “As part of our smart plastics range, we are gradually equipping plain bearings made of high-performance plastics with networked sensors. Our two- and four-hole fixed flanged bearings from the igubal series now also enable condition monitoring and predictive maintenance to prevent unforeseen damage.”

Thomas Preissner, Head of Business Unit, igubal® Spherical Bearings, at igus

More Information

For more information, please visit www.igus.com

Related Product

igus® Launches AI-Powered igusGO App To Help Users Find the Right Motion Plastics Solutions for Their Industrial Application

The app allows users to take a simple photo of their equipment or application — whether it’s a coffee machine, bottling line or excavator. Using AI, the app then recommends suitable igus bearings, linear guides, cable carriers and other products to reduce costs and extend machine service life.