Revolutionizing the Motion Control Industry by Making Piezo Motion Affordable

November 23, 2021

Piezo Motion is the disrupter, reimagining how innovative piezoelectric motor technology can now be more accessible than ever to myriad applications where its advantages bring immense value. Natural and Synthetic Piezo materials have been utilized in sensor and transducer applications for decades, but the practice of harnessing the reverse piezoelectric effect for actuators and motors is less developed.

Piezo technology has a legacy and image of being cost prohibitive for most applications, setting the precedent that only costly high-precision applications can consider it. With technological advancements, this is no longer true, and it is something that engineers and product designers need to be familiar with in order to design for future innovations and learn about the many other benefits of piezo motion. Unlike classic DC motors, the versatile piezo rotary and linear motion motors use very few parts that enable manufacturing volume, yielding a stable and reliable product.

“At Piezo Motion, we recognize that all the cutting-edge products that we depend on today started with an idea and you, as engineers, made it happen. Now, as you design for the future, we have motion solutions to solve problems that would not have been possible before,” explains Piezo Motion’s chief innovation officer, Nic Copley. Piezo Motion’s rotary motors are engineered to provide high-quality and exceptional performance for OEM applications that demand reliable and economical motion control solutions with good power density and lightweight efficiency. The motors have up to 625,000 steps per revolution without any reduction of Torque output. Motors can be driven in open loop mode or are available with integrated encoders for closed loop control.

Energy efficient, the motors consume less than 0.1W at 1rpm. The piezo motor linear actuators are designed with lightweight materials to combine economical cost with superior precision and ultrafast response/start-stop characteristics. Highly energy efficient, Piezo Motion’s linear motors consume zero power to maintain a hold position at full force. Linear motors can step at 50 nanometer increments and will respond in 30 to 50 microseconds. Non-magnetic configurations are possible, enabling use in specialised applications where traditional DC motors cannot be used. These motors are also immune from electromagnetic (EM) and radio frequency (RF) interference and have no emissions.

The unique form factor of Piezo Motion devices enable fitment into compact spaces. The direct drive characteristics of Piezo motor linear actuators make simple linear systems possible, eliminating the need for lead screw drivetrains and yield speeds of over 200mm/s. Highly integrated designs are possible for a wide variety of OEM applications.

The adaptability of the Piezo Motion motor with encoder and drive board offers motion control software via a micro USB connector or can be implemented with a Python API or a serial command set. As demands for our devices to be smarter, more accurate, smaller, more efficient and cost-effective rise daily, engineers are forced to innovate at a rapid pace. At Piezo Motion, we have pushed the envelope of the current motion technologies, enabling new opportunities.

Piezoelectric motors provide a breakthrough in all of those key needs, and we continue to extend the capability of our products and hence the value they can offer. The key technical elements of Piezo Motion motors come from years of experience in scientific research and development in how to control the Piezo materials, preserve energy transfer and mitigate energy loss in piezo motors. Piezo Motion holds numerous patents for its piezo technology, devices and applications. The company’s know-how and its multi-million dollar investment to develop the technology and its portfolio of affordable motion products make it a standout in the industry.

“As precision motion continues to play a larger role in medical devices, surgical robots, wearables, automation, and drones for example, the use of Piezo Motion’s technology will become common place because of the scalable and affordable motion solutions we have developed,” says Hassan Kotob, chairman and CEO at Piezo Motion.

If piezo motors seemed unattainable, think again. Piezo Motion’s ultrasonic piezo motors are used around the world in diverse applications – from medical devices, laboratory instruments, electronics, printing and automation to traditional piezo industries including optics, semiconductor, photonics, nanotechnology and research.

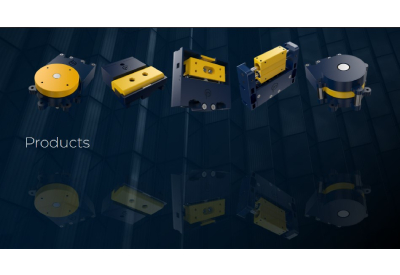

Discover the full range of products available by clicking here