Allied Electronics & Automation Offers Phoenix Contact’s New XTV Terminal Blocks With Push-X Direct Connection Technology

January 19, 2023

Allied Electronics & Automation, a trading brand of RS Group plc (LSE: RS1), a global omni-channel provider of product and service solutions, is proud to offer Phoenix Contact’s new XTV terminal blocks with Push-X connection technology. The new XTV terminal blocks are the first products on the market to incorporate Phoenix Contact’s breakthrough Push-X direct connection technology, which enables easy, flexible, and virtually tool-free wiring and rewiring with minimal force, reduces installation times for all conductor types and cross sections, and paves the way for automated wiring.

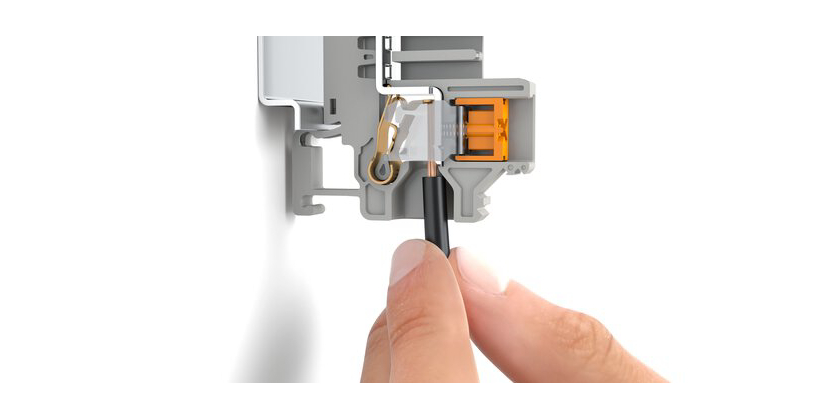

Push-X connection technology features an extremely efficient design with a pretensioned contact spring that supports the connection of stripped rigid and flexible conductors with or without ferrules. The contact spring is designed to be triggered when even the smallest flexible conductors just lightly tap the release surface inside the clamping chamber. Once triggered, the contact spring establishes a safe, effortless, and durable connection with the conductor. To release a connected conductor, users simply press the orange force-guided pusher. When it reaches its end position, a locking mechanism on the leg spring snaps back into the pusher notch and pretensions the contact spring for rewiring. The depressed position of the pusher indicates that the clamping chamber is open for mating. When it’s flush with the terminal, the clamping chamber is closed.

“Push-X technology is an innovative milestone in Push-in connection technology,” said Klaus Firschke, Senior Director of Development & Product Marketing – Industrial Cabinet Connectivity at Phoenix Contact. “Push-X connection technology can accommodate all types of conductors with direct wiring without the need for tools or force, making it one of the fastest, most flexible, and most efficient connection technologies on the market. I am firmly convinced that this connection technology will be the way forward for the entire industry and that our new XTV terminal blocks with Push-X technology will enable impressive new efficiencies in a wide range of industrial applications.”

Klaus Firschke, Senior Director of Development & Product Marketing – Industrial Cabinet Connectivity at Phoenix Contact

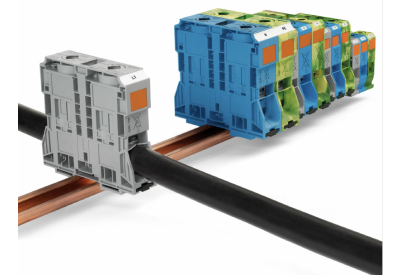

Phoenix Contact’s new XTV terminal blocks with innovative Push-X connection technology have a space-saving form factor that allows users to connect conductors with cross sections extending from 6mm² to 16mm² quickly, easily, reliably, and almost effortlessly. The lateral conductor connection of the terminal blocks minimizes the bending radii and supports visible wiring, which is especially advantageous when combined with wire markings.

The XTV terminal block family currently consists of feedthrough, multiconductor, and grounding (PE) terminal blocks with 6mm2, 10mm2, and 16mm² cross sections and features the first QR codes integrated into Phoenix Contact’s product labeling. Scanning the QR code provides customers with direct access to all the up-to-date information and relevant services and support they may need to quickly and effectively deploy and continuously operate the terminal blocks.

In addition, XTV terminal blocks with integrated Push-X technology are part of the CLIPLINE complete terminal block system. This means they’re fully compatible with other terminal blocks in the system, including the PTV and PTPOWER lateral spring-cage terminal families with well-established Push-in connection technology, and can be used with standardized accessories.

More information

For more information about Phoenix Contact’s new Push-X connection technology and XTV terminal blocks, please visit the product page.

To compare and purchase Phoenix Contact’s XTV terminal blocks with Push-X connection technology at AlliedElec.com, please click here.

For more information about Allied’s extensive selection of Phoenix Contact products for industrial electrification, networking, and automation applications, please visit Allied’s Phoenix Contact storefront.

For assistance identifying, deploying, and maintaining Phoenix Contact solutions in your industrial applications, please contact your local Allied representative at 1.866.433.5722 or reach out to Allied’s technical support team