XPlanar’s Software-based Rotation Increases Freedom of Movement in Flying Motion

April 29, 2021

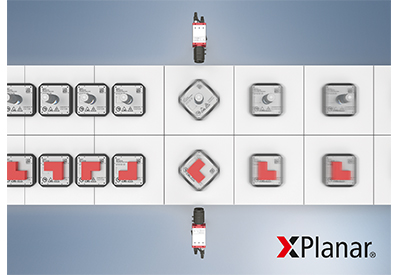

The highly adaptive XPlanar system from Beckhoff now boasts software-based 360-degree mover rotation functionality in addition to other new impressive capabilities. XPlanar enables the contactless, parallel and individual transport of products, with movers flying freely in two dimensions over the XPlanar tiles and executing lifting movements with a stroke of up to 5 mm.

The purely software-based 360-degree mover rotation extends the familiar and highly flexible XPlanar movement range by a full degree of freedom. The XPlanar movers can rotate endlessly around their own axis while levitating at selected positions on the system. The rotation can be executed dynamically with a frequency of up to 10 Hz.

This new XPlanar capability makes a variety of groundbreaking adaptive manufacturing applications possible. For instance, mixing liquids or 360-degree inspection of objects is possible with this additional degree of freedom. Furthermore, the movers can leave the rotation positions with an orientation changed in 90-degree steps, so that the transported workpieces are correctly aligned in accordance with the remaining processing steps.

The 360-degree mover rotation is made possible due to in-house development and the deep integration of the XPlanar system into the PC-based control technology from Beckhoff. A simple update to standard TwinCAT software is all that is needed to implement this powerful new rotation function in existing systems. Special hardware products are not required.

For more information, visit www.beckhoff.com.