SupraMotion – Festo Offering Solutions for Contactless Handling and Weighing of Samples in Clean Environments

May 26, 2025

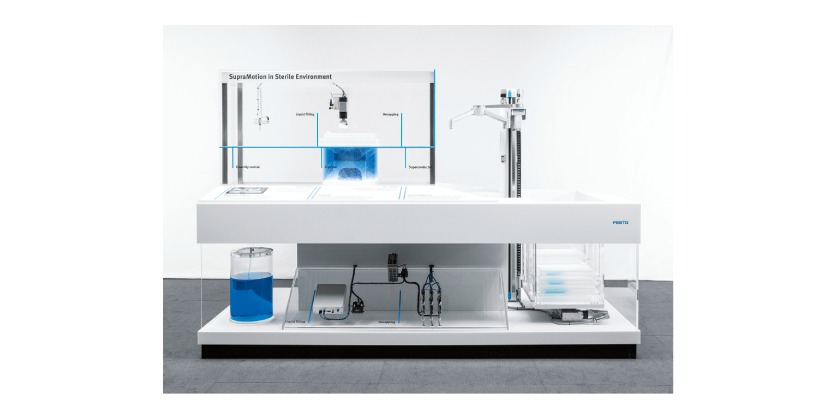

Festo Research has developed SupraMotion superconducting technology as a future concept for automated contactless handling of objects from non-sterile to the clean areas of med labs and pharma facilities. SupraMotion also automates contactless weighing and test tube handling within clean environments.

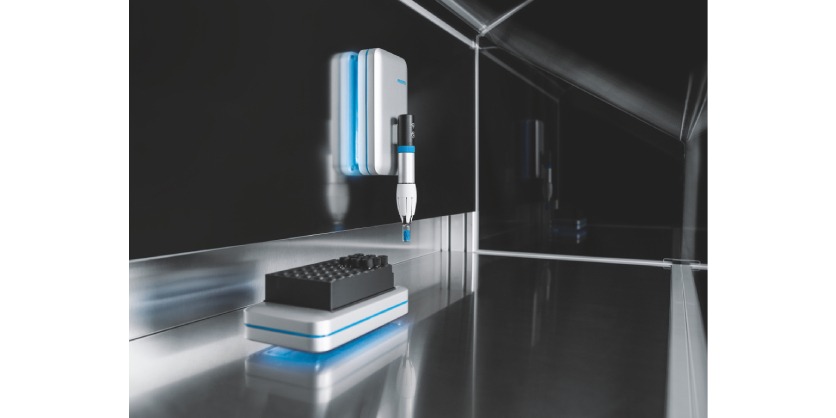

Superconductors are materials with unique magnetic features that lend themselves to contactless handling for dust and abrasion-free operation. The superconductor used in SupraMotion applications anchors the magnetic field of a permanent magnet, creating a strong but invisible bond that keeps the magnet and superconductor at a fixed distance from each other – even through walls, liquids, and vacuum.

Levitation gaps of 10 mm and more are possible, allowing the SupraMotion superconductor to be on the non-sterile side of a barrier and the carrier plate on the sterile side where the plate moves samples and objects through automated processes such as capping/decapping, pipetting, and weighing.

Recently, Festo demonstrated the automated contactless transport of covered microplates from non-sterile holding cells to a clean filling cell. Rather than using horizontal transport, the microplates were moved vertically up a wall and into the clean cell via a SupraMotion carrier. Vertical handling resulted in an ultracompact solution. The filling operation was 100% automated using Festo filling technology and associated solutions, including grippers.

Earlier this year, the company demonstrated fully automated contactless filling and weighing of freeze-dry containers in cleanrooms. The SupraMotion modules and products from the Festo automation portfolio for contactless handling maintained the highest standards of cleanliness.

Festo is seeking pilot projects as the next development stage for this new solution that lowers the risk of contamination in clean environments. Those interested in pursuing pilot projects should write to marketingmgr.us@festo.com

About Festo

Festo, the world’s leading supplier of automation technology and technical education, is deploying its products and services to meet the challenges of digitization and smart production. Founded in 1925, the family-owned company based in Esslingen, Germany supports a wide range of needs for advanced solutions in factory and process automation. In Canada, Festo has been supporting Canadian industry for 50 years, continuously elevating the state of manufacturing in this country with innovative products, optimized motion control solutions and unrivalled support.

Globally, some 300,000 customers put their trust in the company’s pneumatic and electric drive products and technology. In addition, Festo Didactic provides state-of-the-art training equipment and educational programs for industrial companies and educational institutions – about 56,000 customers worldwide. The Festo Group registered sales of €3.45 billion in the 2024 financial year and is represented worldwide at 250 locations with about 20,600 employees. About 8.8% of its annual turnover is invested in research and development.

More Information

For more information on SupraMotion and other Festo Life Science solutions – dispensing liquids, controlling gases, and handling and gripping vials ‒ visit the Festo Laboratory Automation webpage. Visit http://www.festo.ca/ for the company’s range of products.

Related Story

Festo Features Multi-Axis Positioning Systems at Automate

Festo showcased at Automate 2025 its most innovative automation solutions, including multi-axis positioning systems. Festo positioning systems can be specified in minutes and, after delivery, installed and functioning in hours instead of weeks.