Siemens Launches Intelligent Link Module to Boost Industrial Automation Data Transparency

October 18, 2024

- Complete data transparency down to the field level

- Field-level load feeders are seamlessly integrated into the automation system

- Detection of faults, deviations, and maintenance requirements facilitates diagnosis and enables preventive maintenance

With the SIRIUS 3RC7 intelligent link module, Siemens now offers a quick and easy way to gain complete data transparency down to the field level. The plug-and-play expansion module combines information technology (IT) and operational technology (OT) with minimal installation and commissioning effort. This means that the data available at the load feeders can be used efficiently. As part of the leading automation concept Totally Integrated Automation (TIA) from Siemens, the SIRIUS 3RC7 intelligent link modules are seamlessly integrated into the existing automation environment. SIRIUS 3RC7 is part of the SIRIUS modular system, the comprehensive portfolio for industrial controls.

“Transparency down to field level is becoming increasingly important. However, many devices are not connected to the automation system, which means important data is missing. By digitalizing the field level, we are creating a new dimension of transparency and enabling data-driven decisions,” said Andreas Matthé, CEO of Electrical Products at Siemens Smart Infrastructure.

A variety of load feeder parameters can be collected and evaluated directly, including voltage, current, phase imbalance, number of overload trips, and much more. The integrated diagnostic functions help detect and correct faults more quickly. Among other things, the data can be used for Senseye Predictive Maintenance, Siemens’ comprehensive solution for predictive maintenance. It uses artificial intelligence, for example to examine current fluctuations for anomalies that indicate a defect. This significantly increases the planning reliability for maintenance, availability, and cost-effectiveness of the system.

Thanks to full integration in TIA, users receive up-to-date status information in their operating software. In addition, when using special apps such as Node-RED, they have access to a dashboard to quickly identify bottlenecks. This prevents downtime and increases the availability of the system.

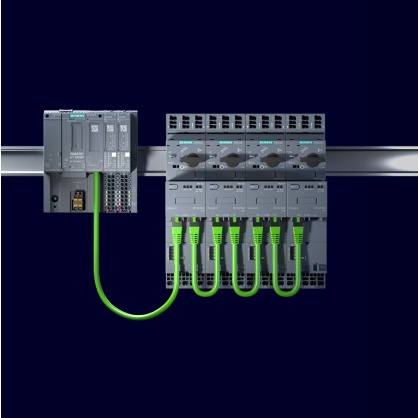

The SIRIUS 3RC7 intelligent link modules integrate perfectly into the compact SIMATIC ET 200SP I/O system as well as any other common automation system. Up to 16 load feeders can be connected per BA-Send module bus adapter in order to benefit from the simple commissioning, individual scalability, and maximum flexibility offered by the SIMATIC ET 200SP.

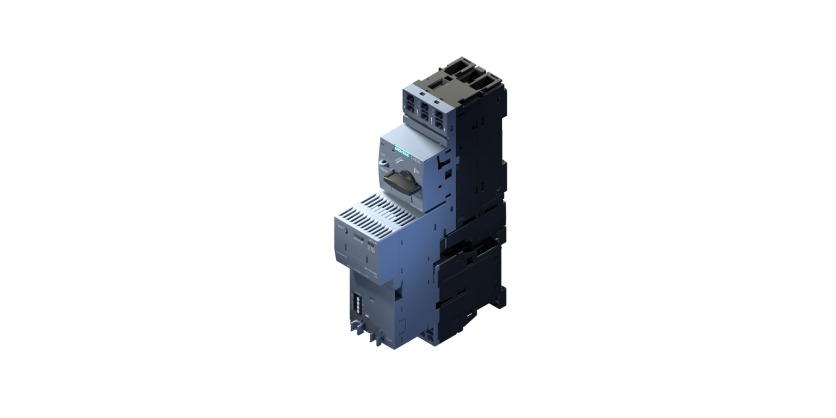

In conjunction with SIRIUS switchgear and the compact SIMATIC ET 200SP I/O system for control cabinets, SIRIUS 3RC7 intelligent link modules ensure reliable and efficient data exchange between OT and IT. The addition of the new SIRIUS 3RC7 intelligent link module to the existing SIRIUS portfolio (modular system) has created a new, enhanced product: the SIRIUS Intelligent Load Feeder. The SIRIUS Intelligent Load Feeder is a pre-assembled digital feeder consisting of a SIRIUS 3RV2 circuit breaker, a SIRIUS 3RT2 contactor, and the intelligent link module.

Related Story

Siemens Xcelerator: Scaling Roll-Out of Generative AI with Siemens Industrial Copilot

At Hannover Messe 2024, Siemens presents the first generative artificial intelligence (AI) product for engineering in an industrial environment. The Siemens Industrial Copilot, the generative AI-powered assistant, is now seamlessly connected to the Totally Integrated Automation (TIA) Portal. This will enable engineering teams to find the right help topic and to generate a basic visualization and code faster for programmable logic controllers (PLC).