SCHUNK’s New High-Performance Universal Gripper

November 26, 2021

With the new optimized 2-finger parallel gripper JGP-P, SCHUNK is further expanding its family of universal grippers alongside the SCHUNK flagship PGN-plus-P. The successor of the JGP has the advantage through its increased gripping force, flexibility in application, and a variety of query options. With this development, the gripping system specialist continues to raise the bar when it comes to price/performance optimized pneumatic grippers.

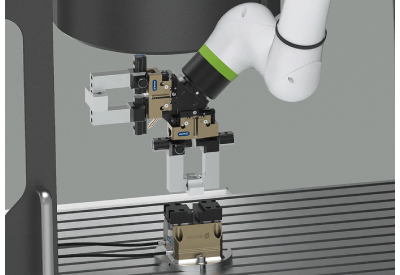

For all users who have flexible, strong and cost-effective on their criteria wish list, the new JGP-P 2-finger parallel gripper is a wish come true. It lends a hand with loading and unloading machine tools, assembly work, and pick & place tasks. A whole range of new features makes this possible. This includes the robust T-slot guidance with longer base jaw guide: compared to its predecessor, it allows for the use of gripper fingers that are 30 percent longer. The base jaws are fully guided in the housing in any gripping state. This improves its performance and covers a wider range of different applications.

The JGP-P also has up to 50 percent more gripping force than its predecessor – and that’s at the same size. This is made possible by the increased surface area of the drive piston. This means that the newcomer can easily handle a higher workpiece weight. Users can thus also rely on smaller sizes, which additionally saves costs and reduces the variety of gripper types. This means that the return on investment is at least 10 percent higher. The change from the old JGP to the new JGP-P is possible at any time, as the grippers are fully compatible.

Workpeice Monitoring Made Easy

No less than ten matching sensor systems enable a wide range of interrogation options, such as monitoring the stroke position or workpiece differentiation. Good or bad parts can be sorted quickly and reliably based on the dimensional deviations. From size 64, the JGP-P is also available with diameter 8 inductive sensors.

Flexible mounting options on two sides allow the gripper to be mounted universally and flexibly in three screw-on directions. The supply of compressed air is possible both via screw connection and via the hose-free direct connection. An integrated sealing air connection also improves process stability. This is particularly important after machining workpieces, as the gripper inevitably comes into contact with chips and coolant during cleaning. The integrated sealing air connection prevents penetration into the gripper. Failures due to contamination are now a thing of the past.

Forever a Benchmark

If you are planning more demanding gripping tasks, the PGN-plus-P gripper from SCHUNK is the ideal choice. With its high power density and a unique variety of options, it is considered to be a benchmark all over the world in the field of universal grippers. The premium gripper with optimized multi-tooth guidance offers even greater power reserves and a unique range of accessories. It therefore covers almost the complete spectrum of all automation applications and is also maintenance-free for life.

For more information, visit SCHUNK by clicking here