POSITAL Explosion-Proof Rotary Encoders with UL Certification

July 3, 2025

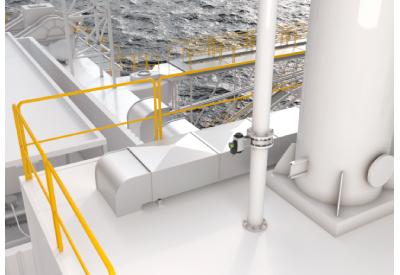

POSITAL’s explosion-proof IXARC incremental and absolute rotary encoders have been certified as complying with UL requirements for operation in areas with hazardous levels of flammable gases, dust and fibers (Class I, Division 2, Group A, B, C and D; Class II, Division 2, Group F and G; and Class III) These devices are ideal for oil and gas installations, chemical plants, woodworking operations, grain handling facilities and fabric production. Certification documents from UL cover multiple encoder configurations. These products have also been certified for compliance with the international ATEX and IECEx standards for Category 3 electrical products operated in Zone 2 and Zone 22 conditions.

POSITAL’s UL-certified encoders feature aluminum or stainless-steel housings designed to eliminate electrical hot-spots that could ignite a fire or trigger an explosion. These housings contain robust magnetic measurement systems that combine highly accurate outputs with the ability to withstand shock loadings up to 100g and sustained vibrations as high as 10g.

IXARC incremental encoders feature several programmable performance parameters. Resolution (anywhere from 1 to 16,384 pulses per revolution) and incremental pulse direction (A before B or B before A) can be modified by simple firmware updates. Likewise, the output driver can be set to either Push-Pull (HTL) or RS422 (TTL). Customers can order the configurations they need pre-set at the factory or can customize their encoders on-site with POSITAL’s convenient UBIFAST programing tool.

Absolute encoders have up to 16-bit single turn resolution and a multiturn counting range of up 20 bits (over a million revolutions). Available communications interfaces include analog, SSI, CANopen, J1939, IO-Link, EtherCAT, Modbus, PROFIBUS and PROFINET. Rotation counters for multiturn versions are powered by an energy harvesting Wigand sensor system. This reduces maintenance requirements by eliminating the need to instal, test and replace backup batteries.

Like other members of the IXARC encoder family, UL/ATEX/IECEx certified models can be ordered with a range of mounting flange designs and shaft configurations. This wide range of configuration options makes it possible to select an encoder configuration that will be easy to integrate into almost any machine or system. Identifyng the right IXARC encoder for a particular application is straightforward. Visit posital.com to find a powerful product finder tool that enables customers to specify the product features required for each application and quickly zero in on the best available products.

About FRABA and POSITAL

POSITAL is a supplier of advanced industrial position sensors used in a wide variety of motion control and safety systems. The company is also an innovator in product design and manufacturing processes and a pioneer of Industry 4.0 (Industrial Internet of Things/IIoT), offering customers the benefits of built-to-order products combined with the price advantages of mass-production.

POSITAL is a member of the international FRABA group, whose history dates to 1918, when its predecessor, Franz Baumgartner elektrische Apparate GmbH, was established in Cologne, Germany to manufacture relays. Since then, the company has played a trendsetting role in the development of rotary encoders, inclinometers and other sensor products. POSITAL has a global reach with subsidiaries in Europe, North America and Asia along with a worldwide network of sales and distribution partners.

More Information

Related Story

POSITAL Adds New Connectivity and Housing Options for TILTIX Inclinometers

POSITAL is extending its family of TILTIX inclinometers by adding Deutsch DTM connectors as a new interface option. “TILTIX tilt sensors are notable for their reliable performance under difficult operating conditions” comments Christian Fell, Head of POSITAL’s operations in the Americas. “Deutsch connectors are also designed for harsh conditions, especially on vehicles and mobile machinery. Making them available to our customers was a logical step.”