New Emerson Solution Reduces Energy Costs, Carbon Emissions for Manufacturers

November 7, 2024

Energy Manager simplifies electricity monitoring, tracking real-time use to identify opportunities that can minimize waste and reduce emissions by up to 30%

Emerson has launched its new Energy Manager solution, a pre-engineered hardware and software offering designed to simplify industrial electricity monitoring with quick setup and intuitive operation. Ready out of the box, the Energy Manager solution monitors asset energy use in real time, allowing manufacturers to gain deeper insight into energy consumption and operating costs, lowering carbon dioxide (CO2) emissions and maximize energy and operational efficiency.

Most manufacturers, including original equipment and industrial manufacturers, consumer packaged goods companies and food and beverage producers, face mounting pressure to increase productivity while reducing energy use and environmental impact. Yet industrial machinery is energy-intensive, consuming high power even when idle. To better meet efficiency and sustainability goals, operators need the best possible visibility into their facilities’ energy use to address waste and inefficiencies.

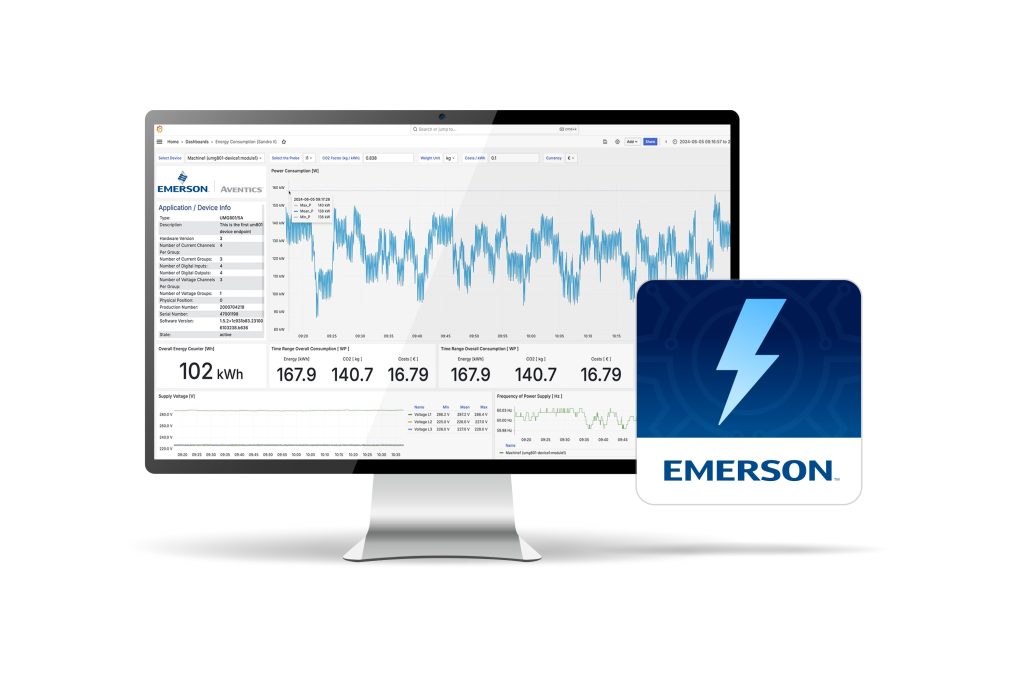

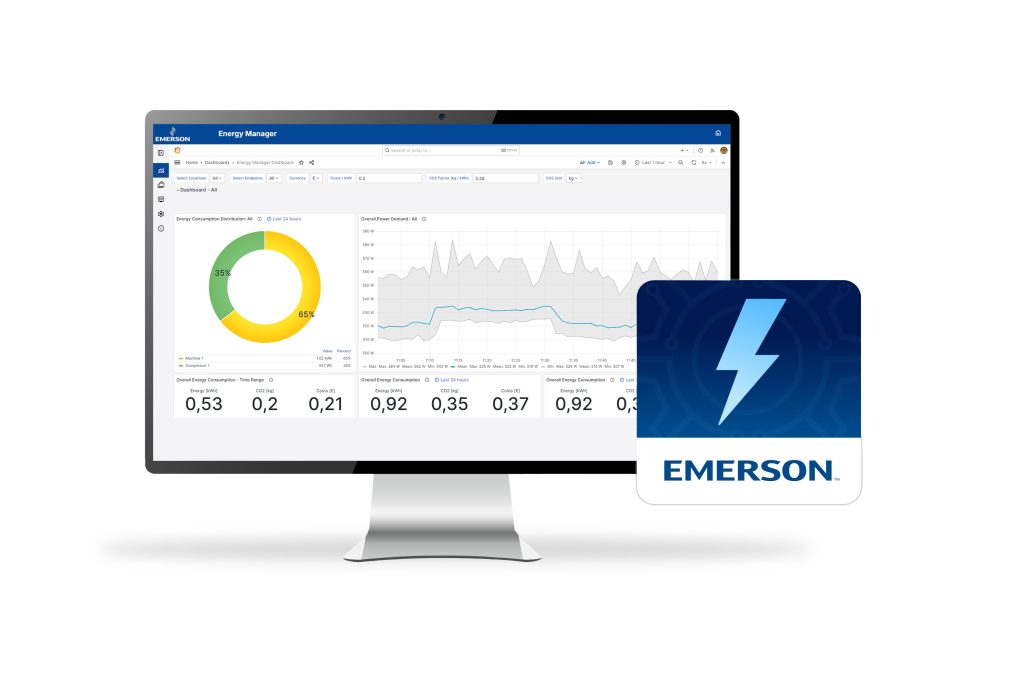

Emerson’s Energy Manager solution provides energy measurements in real time, allowing plant managers to quickly view detailed values and see savings opportunities, such as idle consumption and peak loads. The software’s easy-to-use dashboard provides asset-specific energy use, associated costs and CO2 emissions for up to 10 end points (expandable to 50 endpoints with a license).

Emerson’s new Energy Manager solution helps manufacturers cut energy costs and carbon emissions by up to 30%, offering real-time electricity monitoring to identify and minimize waste.

This level of visibility gives organizations greater control to identify idle machines and optimize machine schedules during off-peak hours, reducing electricity use across the plant floor and significantly lowering overall utility costs. Most facilities can reduce energy waste up to 10-30% and carbon emissions by up to 15-30%.

Highly scalable and easy to integrate with new or existing energy meters, the Energy Manager solution makes it easy to commission and quickly realize return-on-investment. The software is available either preinstalled on edge hardware, such as the PACSystemsTM RXi2-BP industrial PC, or as a stand-alone application that can be installed in a virtualized environment.

“Reliable, accurate monitoring of energy costs and emissions is becoming invaluable to organizations,” said Eugenio Silva, intelligent automation product manager with Emerson’s discrete automation business. “Our new Energy Manager solution gives operators, facility managers and corporate sustainability teams greater visibility and deeper understanding of energy consumption and operating costs at all times. This can better position companies to track and reach targets, comply with regulations, and reliably reduce environmental impact.”

For more extensive media and utilities monitoring, the Energy Manager can be paired with the Emerson Compressed Air Manager to provide a streamlined view of energy costs and compressed air usage of machines across a production line, factory and site.

More Information

For more information about the new Emerson Energy Manager solution, please visit https://www.emerson.com/en-us/catalog/emerson-energy-manager.

Related Story

Emerson’s New Compact, Rugged PC Built to Connect Industrial Floor to Cloud

Emerson has announced the new PACSystems™ IPC 2010 Compact Industrial PC (IPC), a rugged industrial computer designed to handle a wide range of machine and discrete part manufacturing automation applications. The new solution is designed to serve manufacturing sites and OEM machine builders who need a ruggedized, compact, durable IPC to cost-effectively support their Industrial Internet of Things (IIoT) and other digital transformation initiatives.