New Carbon Steel Flowmeter Provides High Chloride Resistance at an Interesting Price Point

July 29, 2025

New Carbon Steel Flowmeter Provides High Chloride Resistance at an Interesting Price Point

For upstream oil producers, elevated chloride content in high-pressure steam processes is the bane of flowmeters employed in thermal recovery methods like SAGD. For those operations, Endress+Hauser has developed a new special-purpose derivative of its Proline Prowirl O 200 with carbon steel rather than a stainless-steel sensor body. Like the stainless steel Prowirl O 200, the carbon steel flowmeter employs a casted meter body with standard flanges. This new carbon steel flowmeter represents a better-quality product at an improved price point with a shorter delivery timeline than the legacy model it supersedes.

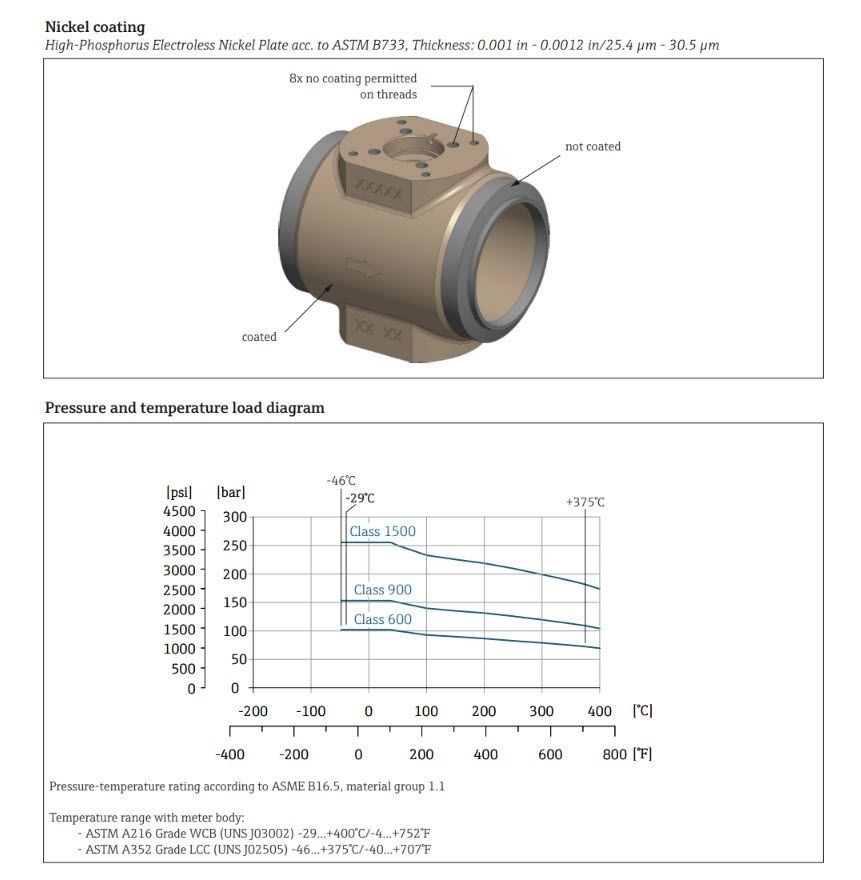

In thermal recovery, high chloride content in steam results principally from using untreated groundwater in the feed boilers and hence in the steam process down the line. The new carbon steel Prowirl O 200-meter body also boasts a special High Phosphorous Electroless Nickel Coating, which produces a uniform coating that further increases corrosion protection versus the previous generation Prowirl C.

This new vortex flowmeter is available in line sizes DN40 to DN150, for pressure ratings of CI.150/CI.300/CI.600/CI.900/CI.1500.

Prowirl 200 O is the high-pressure member of the Prowirl portfolio of vortex flowmeters.

The Prowirl 200 O’s balanced design makes the DSC (Differential Switched Capacitator) sensor resistant to plant vibration, temperature shocks (>150 K/s) as well as water hammer in steam lines. Long-term test measurements have also confirmed that Prowirl vortex flowmeters show no signs of drift even after decades of use (lifetime calibration factor). Thanks to its robust design Prowirl 200 O can reduce installation and operating costs, in addition to significantly increasing plant availability.

The Proline 200 transmitter supports multiple widely used communications protocols, such as HART, as well as PROFINET over Ethernet-APL. Each meter also includes Endress+Hauser’s proprietary Heartbeat Technology for built-in verification of device fitness and performance. It not only checks if the flowmeter’s components still comply with their original reference values but also indicates the presence of any specific systematic faults that could have a negative impact on the device or process performance.

About Endress+Hauser

Endress+Hauser is a global leader in measurement instrumentation, services and solutions for industrial process engineering. Their products – sensors, instruments, systems and services for level, flow, pressure and temperature measurement as well as analytics and data acquisition – set standards in quality and technology. The company further supports its customers with automation engineering, logistics and IT services and solutions.

Founded in 1953 by Georg H Endress and Ludwig Hauser, the Endress+Hauser Group has been solely owned by the Endress family since 1975. Today, the Group is managed and coordinated by a holding company based in Reinach, Switzerland, employing 17,046 personnel across the globe at year end. In 2024, the Group generated net sales of 3.744 euros (C$5.80 billion). Endress+Hauser’s production centres in 12 countries meet customers’ needs and requirements quickly and effectively, while its dedicated sales centres and strong partner network guarantee competent worldwide support.

More Information

Related Story

Endress+Hauser Now Boasts Over 9,000 Patents and Patents Pending

On average, Endress+Hauser filed a patent every working day last year. There were 285 first filings for inventions. The family-owned company was granted a total of 701 patents overall, a figure exceeding the number of first filings as inventions are ultimately registered with multiple patent offices. The Endress+Hauser Group’s portfolio of intellectual property rights now includes over 9,000 active patents and patents pending.