Festo Pre-Assembled Filtration Units Ensure Clean Compressed Air in Food Zones

April 21, 2021

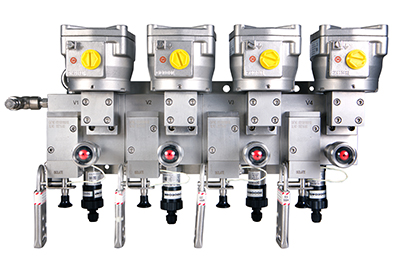

Festo introduces the MS series of filtration products that lower the risk of particle contamination when compressed air comes into direct contact with food or packaging in the food zone. The MS series meets or exceeds the highest industry standards for clean air. Always in stock with guaranteed fast shipping, MS filters arrive assembled with safety and total productive maintenance features typically found as custom add-ons. The units install easily and are priced competitively.

The MS series is designed for food and packaging-in-food-zone applications in the dairy, baking, produce, processed foods, pet foods, craft beer, cold food processing, and beverage industries.

Furthermore, this versatile series is suitable for a wide range of other industries where clean compressed air enhances the longevity and efficient operation of pneumatic cylinders and processes. The three different models in the series – MS4, MS6, and MS9 – not only conform to FDA and US Food Safety Modernization Act guidelines for clean air, but also meet or exceed the top national and international benchmarks, including:

- – Safe Quality Food Institute Codes Edition 9

- – 3-A standard 604-05

- – British Compressed Air Society Guideline 102

- – ISO2200:2005

Pre-configuration and guaranteed fast shipping reduce engineering and purchasing time as well as inventory requirements for OEMs and end users. MS series filtration systems are rated for air flow ranging from the MS4 at 360 l/min to MS9 at 7,800 l/min.

As core Festo products, the popular MS4 and MS6 filtration units are available worldwide and normally ready for shipment within 24 hours. OEMs and end users also have the opportunity to customize this series for unique applications and be assured of quick assembly and product shipment.

As an example of easy ordering, the MS6 filtration system, the most commonly used unit for 2,500 l/min 0.01µm filtration application, has only two ordering numbers, one for left-to-right air flow and the other for right-to-left. Other variations of the MS6 for odor and moisture removal in sensitive applications are equally easy to purchase.

In addition to the three-stage filters, MS air preparation units come standard with a lockout/tagout feature for operational safety. An exhaust valve, another standard feature, safely evacuates air from the system when filters are changed. Once the pressure point is set, a lockable filter regulator prevents tampering. Visual-cue red/green gauges support total productive maintenance initiatives by indicating to personnel that the unit has the correct/incorrect pressure range and whether filters require replacement. Filter drains are manual, ensuring that condensation droplets do not fall onto the facility’s floor and pose a risk of contamination. A corrosion resistant housing supports extended service life. The MS series installs easily and is compatible with a wide range of fittings from NPT 2 all the way down to G 1/8.

For more information, visit www.festo.,com.