Festo Customer Solutions Extended Throughout North America

April 17, 2024

Festo Customer Solutions reduces multi-panel building costs by as much as 50%

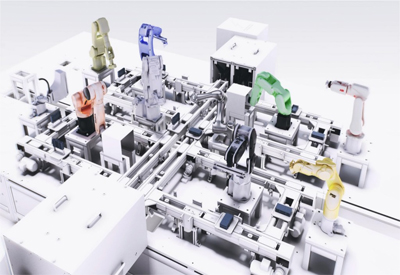

Festo announces that its Customer Solutions department (the company’s fabrication, assembly, and engineering services) is now unified throughout North America. This milestone increases Festo customization capabilities and enables North American engineering companies, system integrators, and original equipment manufacturers (OEMs) to bring projects to market faster with less design, project management, and engineering overhead.

Customer Solutions optimizes the product development cycle by providing:

- Concept generation

- Prototype development

- Streamlined product selection

- Prepackaged mechatronics design

- Assembled and tested solutions

- Streamlined procurement

- High volume build-to-print capability

Festo Customer Solutions supplies control panels

Festo Customer Solutions manages the entire multi-panel control panel acquisition process, beginning with consultation and design and ending with the delivery of assembled, commissioned, and validated panels. These panels are suitable for factory and process automation as well as controls for handling systems.

Panels can include analog and/or digital I/O, electric controls for drives, motors, and actuators, and automation solutions, such as multi-axis handling systems, pneumatic controls, and process control valves. Panels accommodate top communications protocols.

Customers install these UL rated panels on skids and machines, and in clean rooms (NEMA 4X), mechanical rooms (NEMA 4/12), and hazardous areas (NEMA 4X and Class 1 Div. 2). By utilizing one universal part number and one contact person, customers can reduce purchasing costs by as much as 50% while enhancing process reliability and boosting productivity.

Engineering firms, system integrators, and OEMs improve market acceptance by partnering with a global supplier and bringing Festo’s global support into the mix. Festo reduces field service costs, boosts energy efficiency, increases uptime, prolongs the health of components through clean air, offers hot swap valve replacement capabilities, and delivers the benefits of a single source supplier with a robust global supply chain.

More Information

Visit Festo for the full range of products and Customer Solutions information.

Related Product

Festo’s Smart Proximity Switch Commissions Itself for Time Savings that Add Up

There are indeed rewards for machine builders who sweat the small stuff. The latest iterations of many tiny but essential components like sensors, cameras, and switches can pack a great deal of innovation for their diminutive size.