Advancing Electrocaloric Research with FLIR Thermal Imaging at Queen’s University Belfast

March 11, 2025

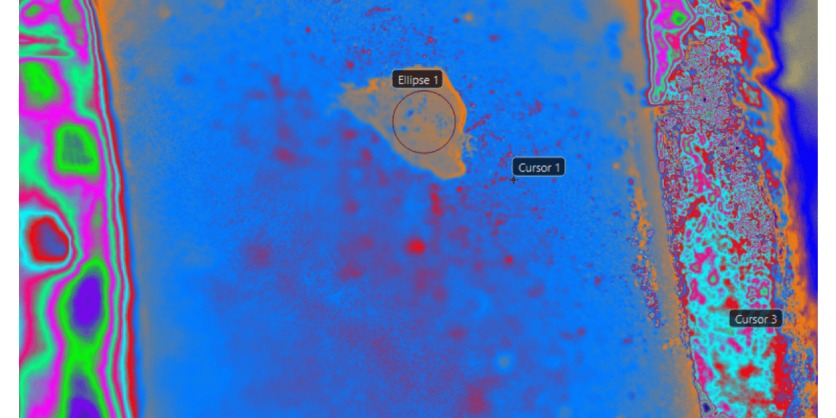

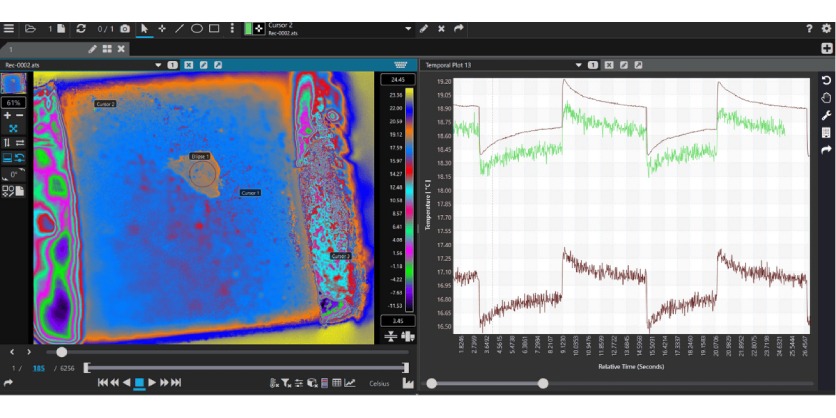

At Queen’s University Belfast, researchers leveraged FLIR’s A8583 cooled mid-wave infrared (MWIR) camera and 5x microscope bayonet lens, and FLIR Research Studio software to investigate the electrocaloric effect—temperature changes in dielectric materials under an electric field.

This combination of high-speed thermal imaging and advanced analysis tools enabled real-time observation of thermal fluctuations, providing deeper insights into material behavior. The ability to visualize and quantify these temperature changes with precision supports the development of solid-state cooling solutions for electronics and sustainable refrigeration.

Challenge

Queen’s University Belfast sought to investigate the electrocaloric effect, a phenomenon where dielectric materials experience temperature fluctuations under an applied electric field. Understanding this effect is crucial for developing energy-efficient, solid-state cooling systems that could revolutionize electronics cooling and sustainable refrigeration. However, capturing these rapid thermal changes required a high-speed, highly sensitive thermal imaging solution capable of detecting minute temperature variations in real time.

Solution

To address this challenge, Butler Technologies provided Queen’s University Belfast with a FLIR A8583 MWIR cooled camera and 5x microscopic optic—a high-speed thermal imaging system designed for scientific applications—along with FLIR Research Studio software for advanced data analysis. The researchers used this combination of cutting-edge hardware and software to:

•Apply a square wave voltage to various samples, including thin wires and multilayer plates

•Observe real-time thermal fluctuations in dielectric materials

•Detect and analyze thermal responses

•Capture transient thermal changes

Results

Using the FLIR A8583 thermal camera and FLIR 5X microscopic optic, researchers at Queen’s University Belfast successfully identified thermal fluctuations at the same frequency as the electrical stimulus, confirming the electrocaloric effect in real-time. This precise ability to capture transient thermal changes enabled a more detailed examination of how electrocaloric materials respond under different conditions, offering insights into their feasibility for solid-state cooling technologies.

The integration of a high-speed cooled thermal camera significantly improved measurement accuracy. With the Stirling engine cooling the detector to approximately 77 Kelvin, the system achieved greater sensitivity and a higher frame rate, allowing for precise thermal photon detection. This capability is particularly valuable for scientific applications requiring the measurement of subtle temperature variations with extreme precision.

These findings contribute to the ongoing exploration of electrocaloric materials for next-generation cooling solutions, with potential applications in electronics thermal management, sustainable refrigeration, and materials science. As industries continue to seek energy-efficient thermal technologies, FLIR’s advanced imaging solutions remain essential for pushing the boundaries of scientific research.

More Information

Explore how FLIR thermal imaging enhances scientific research. Visit FLIR Science Applications to learn more.

Related Story

Ensuring Safety and Efficiency with FLIR Thermal Monitoring for Battery Energy Storage Systems

Battery Energy Storage Systems (BESS) are essential for storing renewable energy and ensuring grid stability. However, their implementation comes with inherent risks, particularly related to lithium-ion battery fires.