Delta Guides the Path Towards Optimized Energy Efficiency in Gigawatt-scale Data Centers for AI Training at NVIDIA GTC

March 21, 2024

Delta Guides the Path Towards Optimized Energy Efficiency in Gigawatt-scale Data Centers for AI Training at NVIDIA GTC

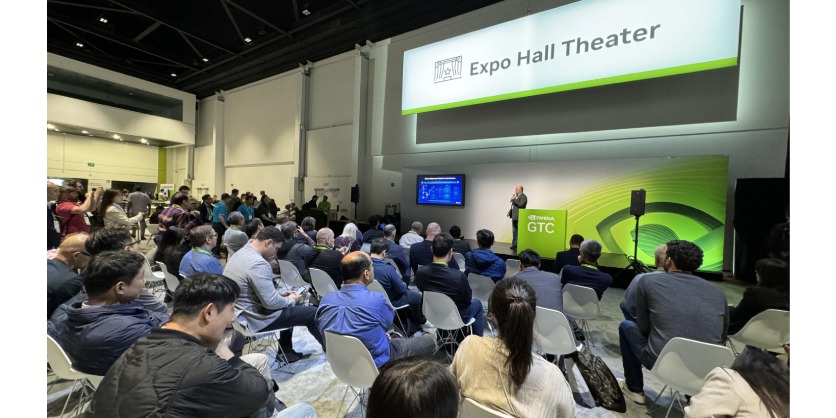

Delta, a leader in power management and provider of IoT-based smart green solutions, has offered an in-depth presentation at NVIDIA GTC, a global AI conference, to highlight its new developments in power solutions from grid to chip to optimize energy efficiency in gigawatt-grade data centers for AI training. This includes Delta’s on-site displays of ORV3 racks, the 33 kW power shelf and the innovative board-level DC/DC Converters VR Series, featuring game-changing vertical power delivery architecture to increase TVR efficiency of output voltage for GPUs to over 94%*.

Delta’s vision to enable HVDC 800Vdc distribution inside data centers with a modular Solid State Transformer (SST) cabinet and a 1OU 80kW DC/DC Power Shelf design to convert 800Vdc down to 50Vdc bus voltage on the rack level was also highlighted in the presentation.

Ralf Pieper, the R&D Director of Delta’s Custom Design Business Unit, said, “As the proportion of GPUs increases in AI computing, global power consumption from data centers is expected to more than double to over 1 trillion kWh by 2026**. Between 2010 and 2022, Delta’s solutions helped our customers worldwide save over 39.9 billion kWh of electricity***. Our unique expertise in high-efficiency server power and DC/DC converters, as well as ICT and energy infrastructure, allows us to spearhead the development of groundbreaking solutions capable of supporting the AI megatrend by optimizing the grid-to-chip power conversion cycle.”

In his presentation, titled “Empowering Next-Generation Gigawatt Data Centers for AI Training”, Mr. Pieper underscored that the arrival of gigawatt-scale data centers for AI training and inferencing applications, likely including 250kW racks, is inevitable. This anticipated radical shift in the magnitude of major AI data centers will require the integration of HVDC power from large-scale renewable energy sources to complement electricity grids. To ensure high-efficiency, reliable, and smooth power conversion and delivery to AI computing chips, Delta keeps developing innovative solutions for different layers within the grid-to-chip ecosystem, such as the power solutions featured at Delta’s booth #1134 at NVIDIA GTC:

- ORV3 Racks and 50Vdc Busbars for centralized AI power infrastructure. These include 48kW shelves with 8,000W power output power supply units, boosting efficiency by up to 97.5%, and AC input 33kW shelf models with 5,500W ORV3 HPR units.

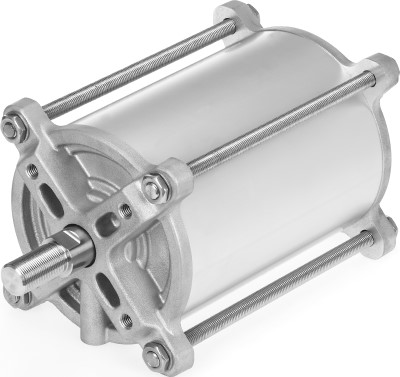

- For GPU on-board power supply, Delta’s DC-DC converters play a key role with high-efficiency 48V to 0.8V power conversion. The new vertical voltage regulator (VR) module activates vertical power delivery for GPUs. It revolutionarily saves ~5%-15% energy loss of the total AI accelerator system by assembling the power module on the back side of accelerator chips.

Other power solutions Delta highlighted and visioned in their presentation include:

- Modular Solid State Transformer (SST) Cabinet design featuring high-efficiency and space-saving medium-frequency transformers for the direct conversion from medium voltage grid (in 10-33kV) directly into 800Vdc. Modularity of the SST switching stages gives both redundancy as well as scalability to adapt easily to the different medium voltage levels, which vary from country to country.

- 250 – 2,100kW Monolithic UPS DPM Gen2 series provides uninterrupted power for AI training data centers, overcoming power outages and addressing diverse power challenges. It sustains continuous operation even at 110% load, boasting industry-leading online efficiency of 97.5%.

- 22kW Peak Load Shaving Shelf (PLSS) with 3x 7.33kW double-slot units and supercapacitors to reduce input side power pressure and improve system reliability. These are ideal for high-repetitive pulsed loads, such as those from NVIDIA’s EDDP curve.

- 1OU 80kW Power Shelf design with 2x rails of 40kW each and isolated DC/DC converters for 800Vdc to 50Vdc power conversion. These power supply unit prototypes are designed to increase efficiency by up to 98% for AI data centers.

Delta welcomes NVIDIA GTC attendees to its booth #1134, where its AI power and thermal management experts will be available for further discussion regarding these aforementioned solutions. Visit the NVIDIA page to learn further about Delta’s work using NVIDIA technology.

Notes:

(*) Specific example featuring single-stage TVR for 0.8 output voltage for GPUs by versus traditional lateral power delivery with two-stage TVR.

(**) 2022 as base year. Source: https://datacentremagazine.com/data-centres/ai-boom-will-cause-data-centre-electricity-demand-to-double

(***) Delta’s high-efficiency products and solutions shipped to customers between 2010 and 2022. Source: https://filecenter.deltaww.com/about/download/2022_Delta_ESG_Report_EN.pdf

More Information

For more information, please visit: www.delta-americas.com

Related Story

Delta Unveils New Innovative AI Server Power Solutions at APEC 2024: ORV3 33kW / 18kW Power Shelves and Vertical Power Delivery Solutions

Delta, a global leader in power and thermal management solutions, announced presenting the next-generation power solutions capable of enhancing the energy efficiency in AI servers and data centers at IEEE Applied Power Electronics Conference and Exposition (APEC) 2024. These include Delta’s Open Rack Version 3 (ORV3) 1OU 18kW and 1OU 33kW Power Shelves featuring power supplies with an impressive efficiency up to 97.5%. The next-generation Vertical Power Delivery Solution, equipped with the new DC-DC Converters VR Series for voltage regulation at the GPU, CPU and ASIC levels, offers improved energy efficiency when compared to traditional lateral power architectures in AI servers.