Epson All-In-One Six-Axis Robot Offers Long Reach at Little Cost

October 27, 2022

Advanced Motion & Controls Ltd. is the Canadian source for industrial robotic solutions by Epson, and one of the most potent options available in this lineup is the VT6L all-in-one six-axis robot. Using next-level technology, this innovative robot offers a reach of 900 millimetres, a six-kilogram payload, and a built-in controller.

Including many of the features common to the manufacturer’s other high-end robots, the VT6L is available from Epson at an ultra-low cost.

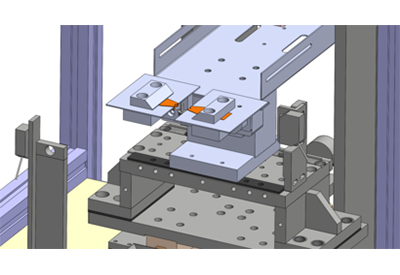

Packaging, assembly and machine loading/unloading

This full-featured industrial robot is the ideal solution for simple parts-transfer automation, whether the user needs it for machine loading and unloading, packaging, parts assembly, or other automation applications. Like other high-end Epson solutions, the VT6L all-in-one six-axis robot has easy-to-use, powerful Epson RC+ development software and simple integration tools. Clean-room (ISO 4) and IP67 options are also available. Among the other features and advantages of this robot from Advanced Motion & Controls:

- •Ease of use. With the intuitive and feature-packed Epson RC+ development software, users can create powerful solutions with little effort.

- •Versatility. This all-in-one solution has a space-saving design with the built-in controller located at the robot base.

- •SlimLine. The compact wrist pitch allows user access to hard-to-reach areas when dealing with confined spaces.

- •Simple cabling design. End-of-arm tooling is easier than ever before, due to the hollow end-of-arm design of the VT6L.

- •Power. Low wattage and power consumption. The robot comes standard with 110 and 220 volts of power.

- •Fast, easy integration. Users can install this all-in-one six-axis robot in mere minutes. It requires less time and money for system integration.

For a closer look at the Epson VT6L all-in-one six-axis robot, check out the video

{videobox}PHuiDi70OT4{/videobox}

Epson offers many other innovative solutions in its award-winning portfolio. Customers can choose from a series of SCARA robots, as well as other six-axis robots and some integrated options. For decades, Epson robots have lowered production expenses, boosted product quality, and increased bottom lines.

For more information abou the VT6L all-in-one six-axis robot by Epson, click here