Bosch Rexroth: The World’s Smallest Electric Subsea Valve Actuator With a Safety Spring

April 21, 2021

At Hannover Messe, Bosch Rexroth presented a disruptive innovation for electrically actuating valves in the subsea process industry. The new SVA R2 Subsea Valve Actuator is the world’s first electric actuator that can replace conventional hydraulic cylinders with field-proven safety technology and without taking up additional space. The integrated electric controller offers precise motion control. Thanks to condition monitoring and a safety spring, the SVA R2 satisfies Safety Integrity Level (SIL) 3 in accordance with IEC 61508 and IEC 61511. The use of internationally standardized interfaces throughout means even more standardization in the subsea process industry. The actuator minimizes energy consumption and is geared toward delicate ecosystems. At the same time, the installation and operating costs are reduced. The functions, operating life and safety of the actuator have already been successfully tested in accordance with international standards. When the SVA R2 is used in subsea factories at a depth of up to 4,000 meters, hydraulic pipes or power units are no longer required. The electric supply pipes which are already installed for sensors are adequate to ensure the reliable operation of the actuators.

Up until now, the operators of process systems have mainly relied on hydraulic cylinders in order to open and close subsea valves with a quarter turn and a defined force. With offshore installations, for example for oil and gas production, these cylinders are supplied by a central hydraulic power unit with hydraulic pipes several kilometers in length. This solution uses a great deal of energy in order to compensate for the cumulated losses and it cannot control the movement with precision. To date, plant engineers and operators have still relied on hydraulic cylinders because they are the only components to offer field-proven safety systems with a mechanical spring in a compact design. The electric actuators which are currently available do not have such a safety function as this is not possible given the size and weight requirements. Approaches designed to ensure safety using subsea batteries cannot guarantee the reliable closing of valves over the required operating life of up to 25 years.

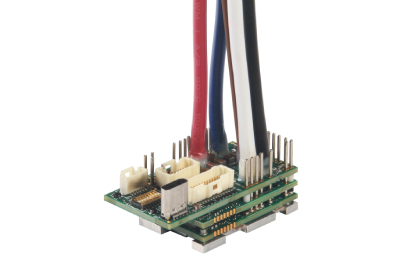

For the agile development of the SVA R2, the Bosch Rexroth team worked closely with a number of suppliers and operators of offshore installations, as well as international universities. The new module comprises a pressure-compensated container that contains an electric drive, a motion control system and a safety device – and can replace the hydraulic cylinders previously used on a 1:1 basis. It requires only one cable for the power supply and communication. The SVA R2 is designed to actuate valves reliably with the power supply that is commonly used for subsea sensors. Switching to compact and safe electric actuators means that the hydraulic pipes several kilometers in length along with the associated power units and controllers are no longer required.

The Subsea Valve Actuator is designed for high volume production. The electronics for the motion control system are from the automotive division and offer proven robustness and reliability. The SVA R2 is protected by a number of patents and is designed to operate for 25 years. Bosch Rexroth relies on globally accepted interfaces throughout and supports plant engineers, operators and offshore service providers when standardizing equipment. The actuators for rotary adjustment complement the SVA L2 Subsea Valve Actuator for linear movements, which received the “Spotlight On Technology™ Award” from the renowned Offshore Technology Conference (OTC) last year.

Bosch Rexroth tests full scale prototypes on a specially built test stand in accordance with the most stringent international standards for subsea applications. Compared to other applications, they set the highest requirements in regards to the functions and safety of the components and modules used. As a result, the SVA R2 is suitable for other applications both below and above water such as hydrogen production, CO2 storage and general applications in the process industry. The first pilot tests are due to start in the third quarter of 2021.