B&R Automation: More Resistant For More Applications

June 18, 2021

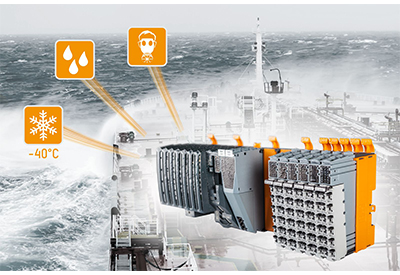

Maritime certification from GL, DNV, KR, LR and ABS for B&R X20 system

Using B&R automation technology in maritime environments is now easier and more flexible than ever thanks to additional certifications by DNV, KR, LR and ABS for the X20 control and I/O system. B&R has also expanded the temperature and input voltage ranges of the X20 system.

Life at sea puts extreme demands on automation components, so the responsible certification authorities subject them to intensive testing. Following certification by Germanischer Lloyd (GL), the recent addition of type examination certificates from Det Norske Veritas (DNV), Korean Register (KR), Lloyd’s Register (LR) and the American Bureau of Shipping (ABS) further attests to the extreme resilience of the X20 control and I/O system.

Down to -40°C

The coated variants of X20 components are now also specified for an even broader temperature range. They can be used safely even at starting temperatures as low as -40°C. The expanded temperature range enables use in cold storage facilities and in polar regions. X20coated modules are standard X20 units whose circuit boards have been specially coated to protect them from condensation, harmful gases and other factors.

Expansive power networks

An expanded input voltage range further simplifies use of the X20 family in maritime environments. The 24 VDC power supply now tolerates deviations from -25% to +30%. That equates to a voltage range of 18 to 31.2 VDC. This facilitates use in power networks that are spread out over large areas, such as those found on ships. Even with the voltage drops that occur over long cables, there is no need for distributed power supplies.