Allied Electronics & Automation Supplies Hardware for Phoenix Contact’s New PLCnext Edge Gateway IIoT Software Solution

April 26, 2022

Allied Electronics & Automation supplies hardware for Phoenix Contact’s new PLCnext Edge Gateway software, a state-of-the-art IIoT edge computing solution designed for data collection in demanding industrial and manufacturing environments. The new PLCnext Edge Gateway software is the latest addition to Phoenix Contact’s PLCnext Technology platform and enables industrial automation and control customers to transmit data from any industrial system to any cloud without having to invest capital to adapt legacy infrastructure.

Once customers download the PLCnext Edge Gateway software onto systems equipped with compatible PLCnext Control hardware, it provides equipment ranging from small machines to entire manufacturing systems with instant access to the cloud. Designed to require zero programming, the new PLCnext Edge Gateway software doesn’t require installers to know ladder logic, structured text or any high-level programming language like Java or C. Instead, the PLCnext Edge Gateway software features a user-friendly web interface that allows users to send previously unextractable data and tags from their existing control system to the cloud and easily manipulate data.

“Getting your data to the cloud sounds easy, and it can be with today’s cutting-edge equipment, but physically transmitting data from legacy industrial control systems to the cloud can be a real challenge — and especially if they’re equipped with PLC systems that are five, 10 or 15 years old, as these systems weren’t developed with the cloud in mind,” said Zachary Stank, product marketing manager for Control, Safety and I/O at Phoenix Contact. “To provide customers with an elegant and economical solution to this challenge, we leveraged the advanced industrial design and programming openness of our PLCnext platform to create an IIoT gateway capable of collecting data from any device or sensor and sending it directly to any major cloud service, including AWS, Azure, Google IoT and Phoenix Contact’s own Proficloud.io. All customers have to do to equip their existing systems with instant access to the cloud is purchase compatible PLCnext Control hardware and download the app.”

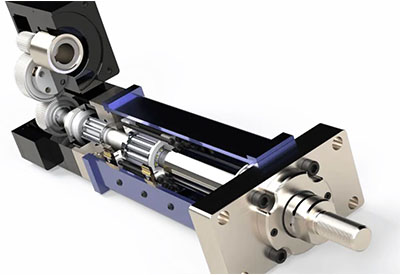

PLCnext Control hardware provides secure, scalable, plug-and-play solutions that comply with the IEC 62443 standard and leverage the new PLCnext Edge Gateway software to serve as an IIoT gateway. Future-minded users can also take advantage of the openness and flexibility of the Linux-based PLCnext Control hardware and PLCnext Engineer software to further develop their industrial control system’s capabilities by programming and configuring applications, adding multiple I/O modules and creating new tags using the programming languages specified in IEC 61131, C++ or MATLAB Simulink.

PLCnext Control hardware compatible with Phoenix Contact’s new PLCnext Edge Gateway software is available as CPU products including PLCnext Control devices for Axioline F Series I/Os, flash memory and the PLCNext Technology starter kit, I/O products including the Axioline F Series and Axioline Smart Elements Series I/O modules and network and communication products including TC and TC mGuard routers.

“With the COVID pandemic and the increased adoption of hybrid work environments, the need for remote access to electronic and automation systems and data has never been more clear or important than it is right now,” said Stank. “Partnering with Allied to launch our new PLCnext Edge Gateway software helps ensure that the requisite hardware is available from the launch date and that people are trained on how it works. Allied can host and train customers on new products at its Fort Worth facility, as well as remotely, which is a huge benefit to Phoenix Contact. Although we can do some of that on our own, having a distribution partner with a knowledgeable internal sales team and existing relationships with the end users interested in leveraging our new technology is hugely beneficial.”

For more information about Phoenix Contact’s PLCnext Technology platform and products, click here