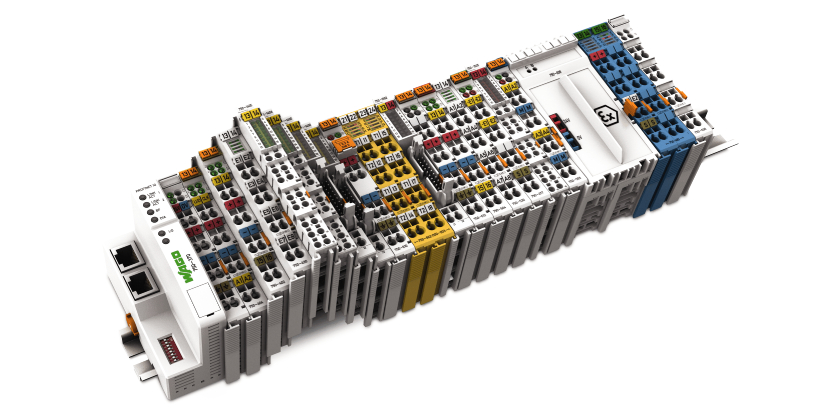

WAGO 750/753 I/O System

February 8, 2023

Decentralized peripherals for every application: Boasting more than 500 I/O modules, programmable controllers and fieldbus couplers, WAGO’s remote I/O system offers all the functions required for your automation needs – and for every fieldbus.

Your Benefits:

- Fieldbus-independent – compatible with all standard fieldbus protocols and ETHERNET standards

- A wide variety of I/O modules for virtually any application

- Also suitable for use in limited spaces thanks to compact dimensions

- International and national approvals for worldwide use

- Extensive range of accessories for marking systems and connection technologies

- Vibration-proof, fast and maintenance-free CAGE CLAMP® connections

Product Overview

Boasting more than 500 I/O modules, programmable controllers and fieldbus couplers, WAGO’s I/O System offers all the functions required for your automation needs – and for every fieldbus. The remote I/O System is the decentralized peripheral for automation. International certifications such as ATEX, UL508 and GL, as well as several additional marine approvals, mean that the WAGO I/O System can be used worldwide for virtually any industry. WAGO’s 753 Series Pluggable Connectors and high-density modules minimize both hardware and system requirements.

The Modular and Compact System for Control Cabinets

The WAGO 750/753 I/O System enables you to not only reduce wiring expenses, but also prevent unplanned downtimes and associated service costs thanks to its high level of reliability. The system also offers additional impressive features: Besides the possibility of custom configurations, I/O modules are available with up to 16 channels to maximize the use of valuable control cabinet space. Additionally, WAGO’s 753 Series Pluggable Connectors expedite on-site installation.

Maximum Reliability and Ruggedness

The WAGO 750/753 I/O System is engineered and tested for use in the most demanding environments, e.g., those required in marine applications. Besides greatly increased vibration resistance, interference immunity and voltage fluctuation range, CAGE CLAMP® spring pressure connections also ensure continuous operation.

Maximum Fieldbus Independence

Fieldbus couplers connect the WAGO 750/753 I/O System to a higher-level control system and support all standard fieldbus protocols and ETHERNET standards. The parts of the I/O system are perfectly attuned to each other for integration into the scalable control solutions of the 750 Series Controllers, as well as the PFC100 and PFC200. WAGO’s e!COCKPIT (CODESYS 3) and WAGO I/O-PRO (based on CODESYS 2) engineering environments are available for configuration, programming, diagnostics and visualization.

Maximum Flexibility

More than 500 different I/O modules with 1, 2, 4, 8 and 16 channels for digital and analog input/output signals are available to meet the wide range of requirements found in different industries, including function and technology modules, modules for Ex i applications, RS-232 interfaces for functional security and much more. Communication modules also make it possible to integrate subsystems and interfaces such as KNX, DALI and AS Interface.