168 Manufacturing Introduces FullShop™ Gen 3 For Affordable Coolant Automation at IMTS

September 11, 2024

FullShop™ Gen 3’s simplified fluid architecture makes system expansion easy, enhances dosing precision and is easy to install for plant personne

168 Manufacturing announces at IMTS the upcoming availability of its reengineered FullShop™ Gen 3 solutions, which makes coolant automation more affordable and easier to install. Built on years of real-world experience and market feedback, Gen 3 uses modern software and electronics, plus a new fluid architecture, to deliver best-in-class value, performance and simplicity.

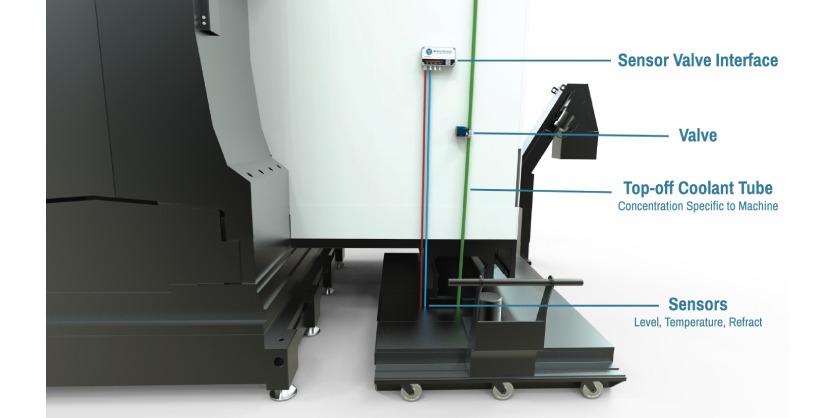

FullShop™ Gen 3 features a small wireless Sensor Valve Interface (SVI) that connects to sensors in the machine sump to monitor coolant temperature, level and concentration. These devices transmit that data back and forth to a Digital Feed Unit (DFU). Using coolant condition data from the SVI and instructions from the FullShop™ App, this compact, powerful and smart pump monitors water and pumps coolant at precise flow rates so any top-off ratio from 0.5 to 20% can be sent into the CNC sumps to hit target concentrations.

Software defines target tank levels and concentrations for each CNC machine. Mixing manifolds near each machine combine this coolant with water from a supply line that runs in parallel with the coolant line. Coolant leaves the manifold and arrives at each sump at the machine-specific top-off concentration. From there, users can use the FullShop™ App as a hub for coolant trends, notifications and more.

FullShop™ Gen 3’s simplified fluid architecture makes system expansion easy, enhances dosing precision and is easy to install for plant personnel. To expand, users simply add more manifolds and piping to extend Gen 3 throughout their plant. FullShop™ systems use common piping and standard plumbing fittings for easy installation.

Once released, FullShop™ Gen 3 will be available as a subscription service, offering a compelling return on investment (ROI) right out of the box.

ABOUT 168 MANUFACTURING

A brand that represents “simply more CNC production,” 168 Manufacturing designs and develops practical automation technologies that improve machine shop efficiency and enable more productive CNC machining. Our current product offering includes the FS120 and FS40 series of FullShop™ Automated Coolant Delivery Systems, which replenish properly mixed coolant concentrations at the machine tool sump. 168 Manufacturing is a brand of Precision Tool Technologies, an advanced manufacturing company headquartered in Brainerd, Minnesota.

More Information

To learn more, visit: 168mfg.com.