Why PLCnext Technology Is the Future of Industrial Automation

July 23, 2025

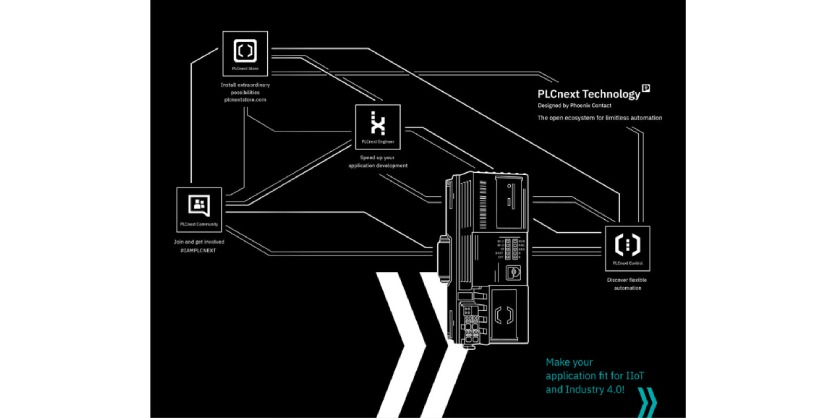

The landscape of industrial automation is changing rapidly. Traditional PLC systems, while reliable, often struggle to keep pace with the demands of modern manufacturing and Industry 4.0 initiatives. Enter PLCnext Technology from Phoenix Contact – a revolutionary approach to industrial control that’s reshaping how we think about automation platforms.

At Proax, they have seen firsthand how PLCnext Technology is transforming operations across Canada. As an authorized distributor with 13 locations nationwide and one in the USA, they are uniquely positioned to help you understand why this open automation platform represents the future of industrial control.

Breaking Free from Vendor Lock-In

One of the biggest challenges facing industrial facilities today is vendor lock-in. Traditional PLC systems often force you into proprietary ecosystems that limit flexibility and increase costs over time. PLCnext Technology takes a different approach with its open Linux-based architecture.

This openness means you are not trapped by proprietary limitations. Instead, you can integrate third-party software and hardware seamlessly, protecting your investment while maintaining the freedom to evolve your systems as technology advances. For facility managers and engineers, this translates to reduced total cost of ownership and greater strategic flexibility.

Multiple Programming Languages, One Platform

What truly sets PLCnext apart is its ability to combine traditional IEC 61131-3 programming with high-level languages like C/C++, Python, and MATLAB Simulink – all running simultaneously on the same controller. This isn’t just a theoretical advantage; it’s a practical solution to real-world challenges.

Your automation engineers can continue using familiar ladder logic and function block programming, while IT specialists can develop advanced algorithms using Python or C++. This collaboration eliminates the traditional silos between OT and IT teams, accelerating development and enabling more sophisticated automation solutions.

Real-Time Performance Without Compromise

Industrial automation demands precision timing, and PLCnext delivers. The platform’s patented task handling system ensures that mixed-code applications work together seamlessly with synchronized, deterministic performance. Whether you’re controlling high-speed manufacturing equipment or managing complex process automation, PLCnext maintains the real-time capabilities that industrial applications require.

This real-time performance extends across all programming environments, meaning you do not have to sacrifice control precision for programming flexibility – you get both.

Security and Safety at the Core

Modern industrial systems face increasing cybersecurity threats while maintaining strict safety requirements. PLCnext Technology addresses both challenges with comprehensive certifications:

- IEC 62443-4-1 ML 3 certification ensures robust cybersecurity from the ground up

- TÜV certifications provide functional safety compliance up to SIL 3/PLe levels

- IEC 61850 compatibility enables seamless integration with power systems and substations

These certifications aren’t just checkboxes – they represent a fundamental commitment to secure, safe automation that you can trust with your most critical applications.

Future-Ready Technology Investment

PLCnext Technology isn’t just about solving today’s problems; it’s designed for tomorrow’s challenges. The platform’s open architecture and Linux foundation provide built-in support for emerging technologies like artificial intelligence, machine learning, and advanced analytics.

The integrated cloud connectivity through Proficloud.io enables Industry 4.0 initiatives without requiring separate gateway devices. With support for over 50 communication protocols including MQTT, OPC UA, and REST APIs, PLCnext ensures your automation infrastructure can adapt to future requirements.

Cost-Effective Implementation

Beyond the strategic advantages, PLCnext offers immediate cost benefits. The basic version of PLCnext Engineer software is free, eliminating the significant licensing costs associated with traditional PLC programming environments. This alone can provide substantial savings, especially for multi-site operations.

The platform’s ability to reuse existing code across different programming languages and projects further reduces development time and costs. Combined with the extensive PLCnext Store ecosystem, you can leverage pre-built applications to accelerate project delivery.

Download PLCnext Technology e-paper

Modular and Flexible Architecture for Every Application

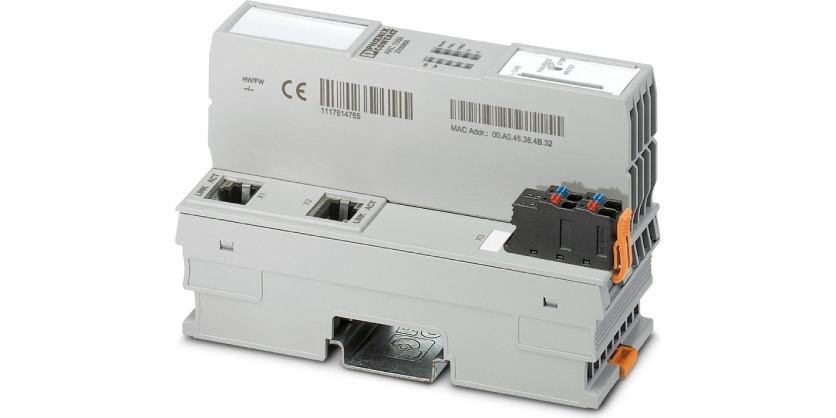

The robust Phoenix Contact Axiocontrol series features several high-performance PLCs in various performance classes, all built on PLCnext Technology. These modular controllers provide exceptional flexibility for your station structure, whether you’re dealing with simple control tasks or complex automation challenges.

The PLCs can be extended with modules for both Axioline and Inline IP20 I/O systems, giving you the freedom to scale your system precisely to your needs. You can also add interfaces and control functions to the left of the PLCnext Control, creating a truly customized automation solution. Security is built in from the ground up – PLCnext Control is secure by design and certified by TÜV SÜD, with security based on a Trusted Platform Module (TPM) where user certificates can be stored.

Core Controller Options:

- AXC F 2152 – Advanced PLCnext Control for direct Axioline F I/O control with dual Ethernet interfaces

- AXC F 3152 – High-performance controller for demanding applications

- AXC F 1152 – Compact yet powerful PLCnext Control solution

Extending Controller Functionality

One of PLCnext’s greatest strengths is its expandability. You can extend your PLCnext Control functions with safety, Ethernet, or AI modules that align to the left of the controller. This modular approach allows you to add additional Ethernet interfaces and optimize your controller for applications involving artificial intelligence and machine learning.

The left-alignable PROFIsafe extensions are fully functional safety-oriented PLCs that extend your PLCnext Control’s capabilities for safety applications up to SIL 3. Additionally, INTERBUS and PROFIBUS controllers are available to integrate legacy remote bus devices into your modern station architecture.

Extension Module Examples:

- Safety Extension Modules for critical safety applications

- Additional Interface Modules for enhanced connectivity

High Modularity with Comprehensive I/O Solutions

PLCnext’s modular philosophy extends to its I/O architecture. The extensive portfolio of I/O modules enables you to build PLC stations that optimally satisfy specific application requirements. You can connect block-modular I/O modules from the Axioline F product family as well as Axioline Smart Elements, which can be assembled flexibly in confined spaces.

The system supports combining both I/O families with up to 63 I/O modules, providing incredible scalability. Beyond basic digital and analog modules, the portfolio includes specialized function modules, with some Axioline F modules available in versions designed for very harsh ambient conditions.

Digital I/O Module Selection:

- AXL SE DO16/1 – 16-channel digital output module for Smart Elements

- AXL SE DI16/1 – 16-channel digital input module

- AXL F DI16/1 DO16/1 2H – Combined 16-input/16-output module for Axioline F

- AXL SE SSDO4/2 2A – Safety digital output module with SafetyBridge technology

- AXL F SSDI8/4 1F – Safety digital input module for critical applications

This modular approach means you’re never locked into a fixed configuration. As your automation requirements evolve, your PLCnext system can grow and adapt alongside them.

Your Partner in PLCnext Success

At Proax, we understand that adopting new technology requires more than just purchasing hardware. That’s why we offer comprehensive support to ensure your PLCnext implementation succeeds:

- Expert consultation from our in-house engineering team who understand both the technology and your industry challenges

- Local inventory across our 13 Canadian locations and 1 US location for fast delivery

- Same-day shipping to minimize project delays

- Free facility visits where our technical experts solve issues hands-on

- Free pickup service for your convenience

Getting Started with PLCnext

Ready to explore how PLCnext Technology can transform your automation strategy? Proax offers several entry points:

Complete Starter Kit (Product #1046568) – The AXC F 2152 starter kit includes everything needed for evaluation: PLCnext Control AXC F 2152, voltage switch, digital input and output modules, analog input and output modules, potentiometer, switch module, PROFICLOUD license, power supply unit, patch cable, and country-specific adapter plugs with comprehensive documentation.

Scalable Solutions for Every Application

PLCnext Technology scales from basic control applications to high-performance edge computing scenarios. Whether you’re implementing a simple machine control system or a complex Industry 4.0 solution, the platform adapts to your needs.

Popular applications include:

- Energy management systems with integrated EMpro capabilities

- Edge computing for real-time data processing

- AI/ML integration for predictive maintenance and optimization

- Multi-vendor system integration bridging different automation islands

Contact their team today for a consultation to learn more about how PLCnext Technology and benefit on your application.

Related Story

Proax Technologies Announces New Calgary Office

Proax’s expansion represents a big milestone for them, and they are eager to better serve their valued clients in the Calgary area. They would like to express their gratitude for your continued support in Proax Technologies. Their success is a direct result of the trust and confidence that clients like you place in them, and they are excited about the opportunity to strengthen this relationship further.