SMC ZGS Vacuum Gripper System: An All-in-One Solution for Automated Handling

March 5, 2025

Modern manufacturing and logistics sectors demand increasingly efficient and reliable automation solutions, especially when it comes to handling delicate or irregularly shaped items. Available through Proax, SMC’s elite distributor, the ZGS Vacuum Gripper System (Foam Type) represents a significant advancement in this field, offering a comprehensive solution for palletizing and depalletizing applications, particularly for corrugated cardboard and similar materials.

Comprehensive Integration in a Single Unit

What sets the ZGS Series apart is its all-in-one design. Rather than requiring separate components that need to be assembled and integrated, this system combines all essential functions required for adsorption:

- Ejector unit with newly designed ejector

- Supply valve and release valve

- Integrated silencer

- Pressure switch

- Robot mounting flange

- IO-Link compatibility (on select models)

This integration translates to significant time savings during installation – simply connect one electrical cable and air piping, and the system is ready for operation.

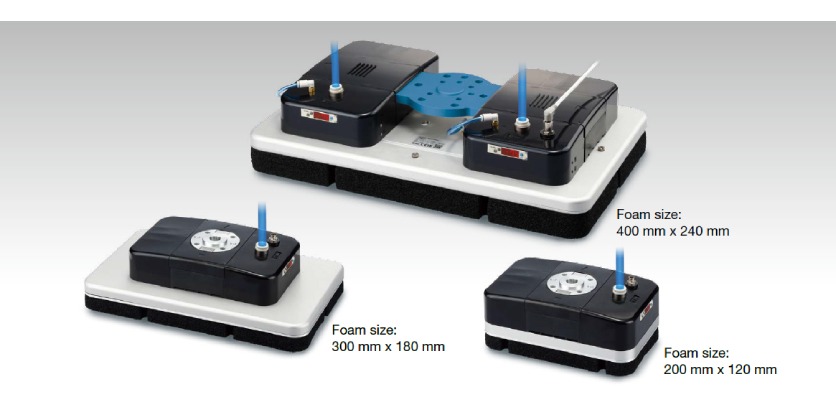

Versatile Size Options for Various Applications

The ZGS Series is available in three size configurations to accommodate different handling requirements:

- 400 mm × 240 mm (lifting force up to 2144 N at -75 kPa)

- 300 mm × 180 mm (lifting force up to 880 N at -63 kPa)

- 200 mm × 120 mm (lifting force up to 440 N at -63 kPa)

Each size option can be outfitted with foam of either 20 mm or 30 mm thickness, allowing for optimal adaptation to workpieces with different surface irregularities.

Enhanced Performance Features

The system incorporates several innovations that improve performance and efficiency:

Energy Efficiency

The newly designed ejector reduces air consumption by up to 15% compared to previous models while maintaining excellent vacuum performance. This translates directly to lower operating costs and reduced CO2 emissions.

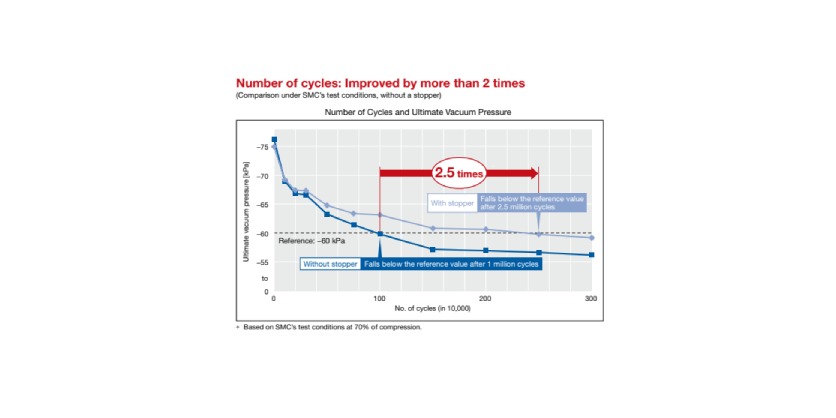

Improved Foam Durability

The vacuum saving valve type includes a stopper that regulates foam compression during suction, reducing cell collapse and extending service life by more than twice compared to models without a stopper.

Selectable Suction Plate Types

Two suction plate options address different operational needs:

- Vacuum saving valve type: Excellent for handling multiple workpieces or when the workpiece is smaller than the suction plate

- Fixed orifice type: Optimal when the workpiece is approximately the same size as the suction plate

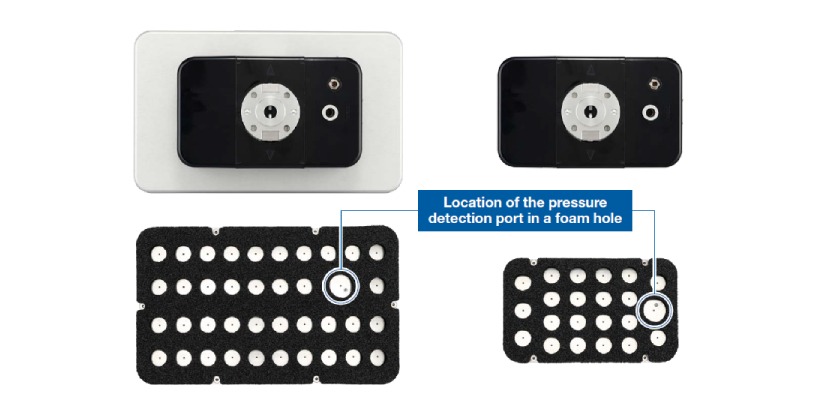

Built-in Pressure Switch with Selectable Detection Ports

The system features a built-in pressure switch that can detect pressure either in the base plate or within a foam hole, providing flexibility in monitoring and control capabilities.

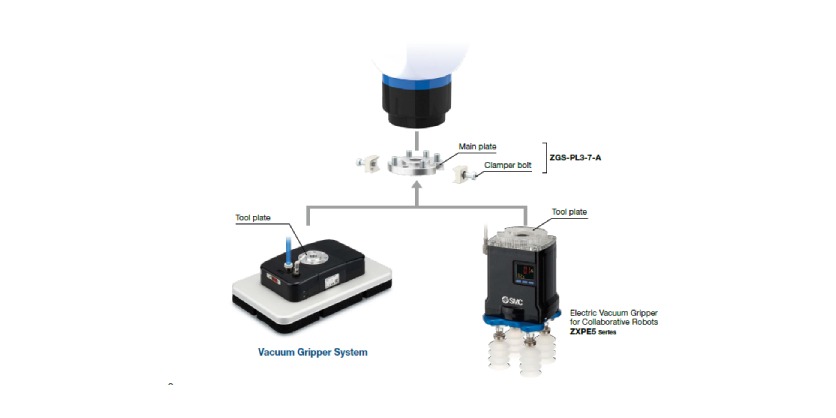

Broad Compatibility with Collaborative Robots

A major advantage of the ZGS Series is its compatibility with collaborative robots from multiple manufacturers:

- Universal Robots

- Omron/Techman Robot

- Fanuc

- Yaskawa Electric

This broad compatibility makes the ZGS an excellent choice for facilities with existing robotic infrastructure or those planning new implementations.

Easy Maintenance and Tool Changing

The system features a manual changer (for 300 × 180 mm and 200 × 120 mm sizes) that allows for quick tool changes. Tools can be secured by simply tightening two clamper bolts, reducing work-hours associated with changeovers.

Practical Applications

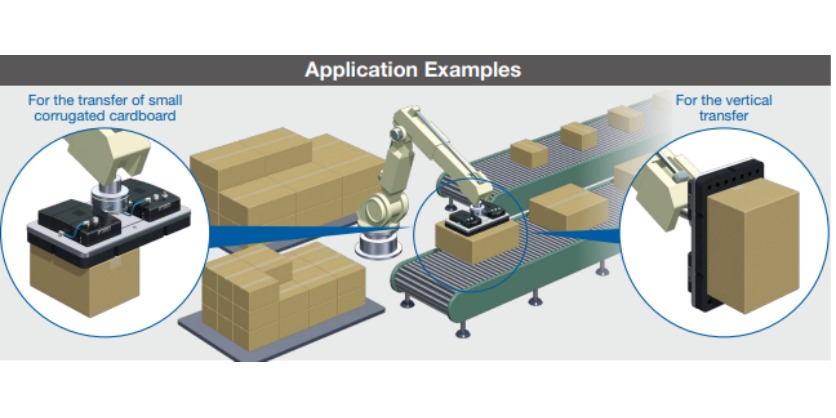

The ZGS Vacuum Gripper System excels in various applications:

- Transfer of small corrugated cardboard

- Vertical transfer operations

- Handling of PET bottles (6 × 2L)

- Transfer of snack cases

- Handling of large cardboard boxes with suction on all corners

Download Proax Technologies’ Technical Specifications

Want to explore the full capabilities of the ZGS Series? Download their comprehensive product catalog with detailed specifications, performance charts, and application examples:

Download SMC ZGS Series Technical Catalog

Conclusion

The SMC ZGS Vacuum Gripper System combines comprehensive functionality, energy efficiency, and adaptability in a single, easy-to-implement unit. It offers the perfect solution for businesses looking to optimize their automated handling processes.

Ready to enhance your automation capabilities? Contact their team today for a personalized consultation on how the ZGS Series can address your specific handling challenges.

Related Story

Proax Technologies Announces New Calgary Office

Proax’s expansion represents a big milestone for them, and they are eager to better serve their valued clients in the Calgary area. They would like to express their gratitude for your continued support in Proax Technologies. Their success is a direct result of the trust and confidence that clients like you place in them, and they are excited about the opportunity to strengthen this relationship further.