Protect Your Production with Festo’s Interchangeable Pneumatic Cylinders

December 1, 2025

By Krystie Johnston

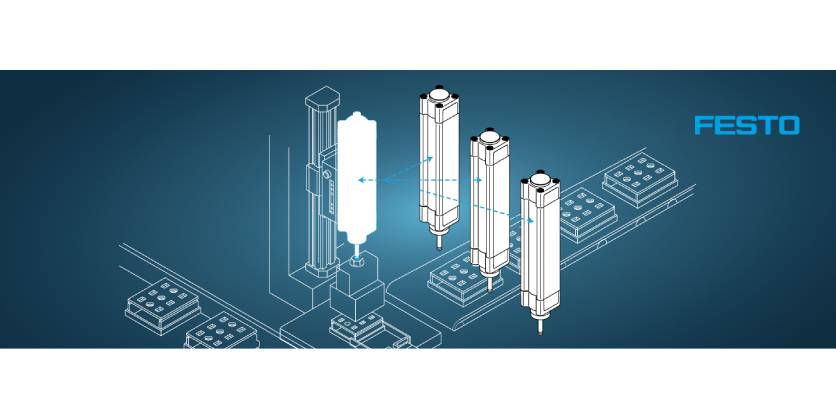

Pneumatic cylinders are the workhorses of industrial automation. They convert compressed air into linear motion, enabling tasks like clamping, gripping, holding, lifting, pushing, and pulling – tasks inherent to production lines and robotics. When these components go down, it can cause significant impacts on production. Avoid these negative consequences with interchangeable pneumatic cylinders from Festo and simplify machine design and maintenance in your facility.

Standardization of popular pneumatic cylinders

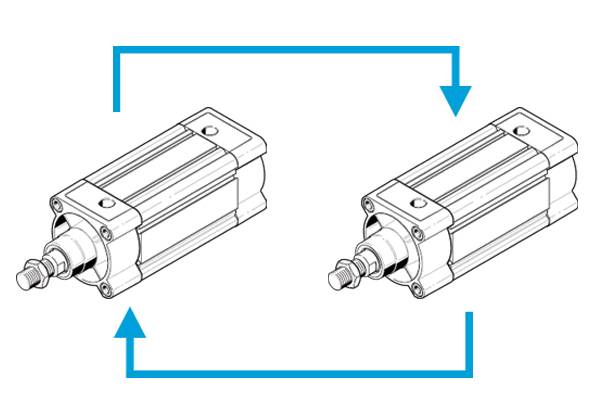

Festo, a leader in motion, offers standardization of popular pneumatic cylinders to national and international standards, simplifying procurement, reducing downtime, and saving time and money. With standardization, Original Equipment Manufacturers (OEMs) and end users do not need to worry about substitution challenges or supply chain vulnerabilities such as availability, pricing, or an individual manufacturer’s distinctive mounting or design. And, with Festo FASTSM, they are in stock and ready to be shipped out the next day, helping businesses eliminate bottlenecks and the frustrations that come with halted production.

Standardization of popular pneumatic cylinders levels the playing field, ensuring that manufacturers adhere to the same mounting interface dimensions so that parts can be readily interchanged. For example, ISO (International Organization for Standardization) and NFPA (National Fluid Power Association) set strict requirements on popular pneumatic cylinders, defining bore sizes, port threads, mounting interfaces, and stroke lengths. For an OEM or end user, these standards indicate that any pneumatic cylinder – regardless of the manufacturer – will fit and be a true drop-in replacement for their required component.

Benefits of ISO-and NFPA-compliant products

Manufacturers like Festo who adhere to national and international standards like the NFPA and ISO make it easy for OEMs and end users to feel confident designing new machines or replacing older ones. Integration and maintenance are easy and straightforward because standardized interfaces and dimensions guarantee the right fit. Moreover, this lends to time and cost savings because, given their wide usage, they are readily available and good to go out of the box, and facilities do not need to keep a large inventory of replacements on the shelf.

But standardization does not negate versatility. If control dimensions and connections are not altered, customizations can be made to fit the application. Many of Festo’s interchangeable pneumatic cylinders can be customized to meet specific application requirements. For example, cylinders can be customized for high heat, additional corrosion resistance, explosion protection, or fabricated with alternative materials, like reduced copper, zinc, and nickel for electric vehicle battery production applications. Festo’s Customer Solutions Group can ensure a seamless customization process.

Festo’s standardized interchangeable pneumatic cylinders

Festo offers popular interchangeable pneumatic cylinders that are ISO-and NFPA-compliant. For example, their ISO 15552 -profile and tie-rod standards cylinders are some of the most popular interchangeable pneumatic cylinders in the industry. Profile cylinders like Festo’s DSBC have bore sizes from 32 to 320 millimeters, and standardized mounting options like trunnion mounts and clevis brackets.

For applications that are tight on space or need lightweight components, Festo’s ADN compact cylinder offers reliable performance and long life – and a lower price. The AND is ISO 21287 certified and meets the international requirements for compact pneumatic cylinders. But they can also be customized for your application, including high heat, additional corrosion resistance, explosion protection, or modified materials.

Festo’s DSNU series is ISO 6432-compliant and designed for durability. It is an adaptation of Festo’s first standardized cylinder, the DSN series, which was sold from 1975 to 2018, demonstrating this round cylinder’s endurance. The DSNU features low-wear PUR seals, a corrosion-resistant stainless-steel piston rod, and sintered bronze bearings.

All three of these interchangeable cylinders offer reliable quality and fast delivery you can count on.

Selecting the right interchangeable pneumatic cylinder

There are a couple of important considerations to keep in mind when selecting the right interchangeable pneumatic cylinder for your application. Once you know what kind of cylinder to use, Festo recommends that you define what your application’s performance needs are. Another thing to keep in mind is the material you need – depending on the application, this could be aluminum, steel, or stainless steel. And decide how you want to mount your cylinder. Finally, determine if you need accessories or other options – Festo has a broad portfolio of pneumatic components to choose from.

A note on “cold spec” cylinders

Standards are constantly changing and being developed. When it comes to interchangeable pneumatic cylinders, it is important to note a distinction between standardized cylinders that meet ISO or NFPA specifications, and “cold spec” cylinders that may appear to meet industry standards but may have slight variations from national and international standards.

If you need assistance, Festo’s online pneumatic sizing and pneumatic simulation tools can help you find the right product, size, and features for your application. Including accessories. And it is free to use, saving you time and money.

What makes Festo unique

Festo stands apart from their competitors for many reasons. They recently celebrated their centennial anniversary as a global company, and multiple double-digit anniversaries around the world. One of the reasons they stand the test of time is because of their commitment to the automation industry and their customers that operate in this space. Festo’s interchangeable pneumatic cylinders are just the tip of the iceberg.

More Information

White Paper: Interchangeable pneumatic cylinders simplify machine design and maintenance

For more information, visit Festo or contact your local distributor.

Related Story

Festo’s 2025 Innovations in Life Science Solve Laboratory Automation Challenges

Festo is a global company headquartered in Germany and present in about 60 countries around the world. In 2024, they had over €3 billion turnover, and more than 8% of that was put into research and development for innovative technologies and emerging markets, like laboratory automation. In this article, Joshua Lamontagne, Product Market Manager for Life Science Products at Festo, shares some of these innovations.