How the NX102 Controller Streamlines Machine Automation with EtherCAT and CIP Safety

November 12, 2024

In today’s manufacturing landscape, the complexity of machine control systems often leads to increased costs, extended implementation times, and challenging maintenance requirements. Omron’s NX102 Machine Automation Controller addresses these challenges head-on by seamlessly integrating EtherCAT motion control and CIP Safety functionality into a single, powerful platform.

Simplified Network Architecture Through Integration

The NX102 controller revolutionizes machine automation by eliminating the traditional complexity of multiple networks and controllers. By combining EtherCAT and CIP Safety capabilities, it delivers:

- Up to 64 EtherCAT slaves with cycle times from 1 to 32ms

- Support for up to 16 CIP Safety connections

- Integration of up to 8 axes of motion control

- Dual EtherNet/IP ports for separate IT/OT network management

This integration significantly reduces installation complexity while maintaining the deterministic performance essential for modern manufacturing operations.

EtherCAT Excellence in Motion Control

The NX102’s implementation of EtherCAT technology brings several key advantages to machine builders and end-users:

- Precise Timing Control: Achieve cycle times as low as 1ms with 0.25ms increment adjustments

- Simplified Wiring: Eliminate the need for managed switches in motion control applications

- Scalable Architecture: Support for up to 64 slaves enables flexible system design

- Cost-Effective Implementation: Reduce hardware costs by eliminating the need for additional network components

Enhanced Safety Integration with CIP Safety

Safety system integration becomes seamless with the NX102’s built-in CIP Safety capabilities:

- Unified Programming Environment: Program both standard and safety control in one software platform

- Flexible Safety Network Design: Implement safety systems locally or distributed across the network

- Reduced Installation Costs: Eliminate the need for a separate safety controller

- Simplified Maintenance: Manage safety systems through the same interface as machine control

Programming Efficiency and Data Management

The controller’s 5 MB program capacity enables efficient programming through:

- Reusable function blocks for consistent implementation

- Secure intellectual property protection with lockable function blocks

- Built-in OPC UA server for standardized data exchange

- Optional SQL connectivity for direct database integration

Real-World Applications

The NX102’s capabilities make it ideal for various industrial applications:

Automotive Manufacturing

- Final assembly operations

- Material handling systems

- Robot cell integration with safety

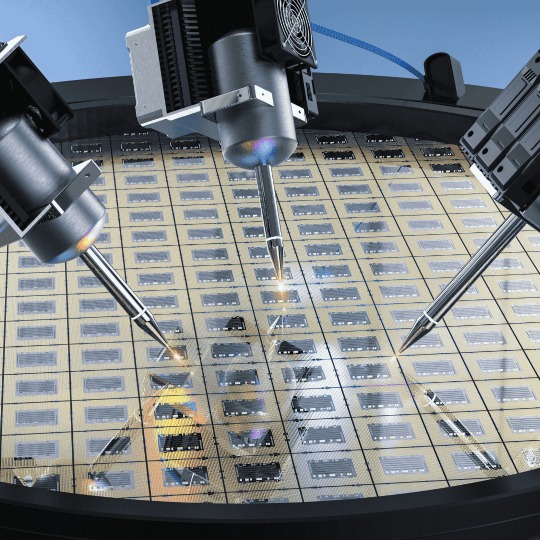

Semiconductor Production

- Wafer positioning systems

- High-precision inspection processes

- Clean room compatible control systems

Packaging Operations

- High-speed sealing systems

- Temperature control applications

- Integrated quality inspection

Success Story: Wire Reduction in Robot Cell Integration

A recent implementation at a major oil field service company demonstrates the NX102’s capabilities:

- Challenge: Complex integration of Fanuc robot with safety controls for five mills

- Solution: NX102-1020 with NX-SL5 CIP Safety Controller

- Result: Eliminated over 100 wires while successfully integrating SQL, OPC, CIP, EtherCAT, and laser marking functionality

Expert Support Through Proax Technologies

As one of Canada’s largest Omron distributors, Proax Technologies brings unmatched expertise in implementing NX102 solutions. Their partnership with Omron enables them to offer:

- Comprehensive technical support

- Local inventory availability

- Custom solution development

- Rapid deployment assistance

- Ongoing maintenance support

The combination of Omron’s innovative technology and Proax’s extensive distribution network ensures that Canadian manufacturers have access to not just cutting-edge control solutions, but also the expertise needed to implement them effectively.

Ready to streamline your machine automation with the NX102? Contact Proax Technologies, your trusted Omron automation partner in Canada. Their team of experts is ready to help you design and implement a solution that meets your specific manufacturing needs.

Related Story

Omron Honours Proax Technologies as 2022 Strategic Partner of the Year

Omron Automation Americas, a provider of industrial automation solutions, takes great pride in naming Proax Technologies as its Canadian Strategic Partner of the Year. This honor underlines Proax’s exceptional dedication and contribution to both Omron and its clientele over the previous year. As a leader in automation distribution, Proax has collaborated with Omron on numerous projects, earning its place as a reliable Canadian partner.