The Future of AI and Vision Technology in Inspection and Quality Control

April 2, 2025

Discover the future of AI in inspection for specialized tasks to versatile solutions.

The landscape of AI and vision technology in inspection and quality control is set to transform with the development of more generalized algorithms. These advanced systems will be capable of tackling a wide range of inspection challenges, moving away from the current trend of specialized algorithms designed for specific tasks. This evolution promises to enhance the versatility and efficiency of AI, making it a more powerful tool for industries that rely on precise and reliable inspection processes.

AI Applications in Vision Technology

AI and vision technology are impacting industries by addressing complex tasks that traditional machine vision systems often struggle with. For instance, AI can read difficult codes and recognize poorly written characters with greater accuracy. Omron’s FH Series is a prime example of this advancement, with upcoming enhancements focusing on advanced defect detection and other sophisticated applications. These improvements not only complement existing systems but also push the boundaries of what is possible in inspection and quality control.

Improved Accuracy and Efficiency

The integration of AI and vision technology brings significant benefits, including cost reduction, increased reliability, and enhanced quality. AI can significantly speed up the inspection process, leading to reduced labor costs and minimized errors. By ensuring that fewer defective products reach consumers, AI helps protect brand reputation and customer trust. These advancements make AI a valuable asset in maintaining high standards of quality and efficiency.

Overcome AI Implementation Challenges

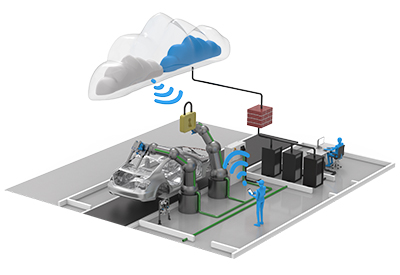

While the benefits of AI and vision technology are clear, implementing these systems comes with its own set of challenges. Gaining organizational buy-in, ensuring data availability, and addressing interoperability issues are common hurdles. However, solutions like Omron’s Sysmac platform are designed to facilitate seamless integration and communication between different systems, making the implementation of AI more straightforward and effective. Overcoming these challenges is crucial for fully realizing the potential of AI. By embracing the evolution of AI and vision technology, industries can look forward to a future where inspection and quality control are more efficient, accurate, and versatile.

More Information

Related Story

The Fundamentals of Machine Vision in Automation: What You Need to Know

Machine vision has a place in many industries, including food & beverage, automotive, semiconductor, life sciences, and more. In this article, Ryan Marti, Product Manager – Industrial Cameras at Omron Automation walks us through the fundamentals of machine vision in automated processes and holds a lens to look at Omron’s products and solutions that are relevant to any of these industries.