Festo’s Legacy of Innovation and Technical Education Forges New Pathways to Lifelong Learning

July 4, 2025

By Krystie Johnston

Festo has a long history of innovation in technology, automation, and education. This year, the global company celebrates its 100th anniversary, and Festo Didactic, the training arm of the company, celebrates 60 years. When Festo began in 1925, automation was unheard of. They helped shape it by developing innovative technologies and teaching others how to use them. Today, Festo is a leader in motion and technical training, with more than 20,000 employees in over 60 countries.

Becoming a leader in these areas has taken decades of practice and partnerships with industry, educational institutions, and organizations like WorldSkills and SkillsUSA, where a shared vision to create a better society helps to solve the challenges of our time. In this article, Daniel Rodriguez, Director of Sales for Festo Didactic North America, discusses some of Festo’s innovations in automation and technical training. Rodriguez holds a BS in Industrial Engineering and an MS in Engineering Management, and has been with Festo for about forty years, working in engineering, product development, and leading global education initiatives.

A pivotal moment and a turning point for the company

Festo is a family-owned company that began in Germany, and they specialized in manufacturing woodworking machines. In 1950, one of the founders’ sons attended a trade fair in Chicago and discovered pneumatics. Rodriguez explains that this was a turning point for the company. By mechanizing aspects of their machines, they realized that these automation processes could be applied to industry at large.

“The company pivoted to producing pneumatic devices, along with application guides and training materials. It was a time when they had to learn how to use those products. You just cannot give someone a cylinder [and expect them to know how to use it]. You have to show them how it is used.”

The development of these application guides and training materials gave birth to what would later become Festo Didactic: the division of Festo dedicated to training. Rodriguez says that Festo Didactic is primarily dedicated to training in public education, and partners with technical colleges and universities. He says they have an industrial workforce division as well that provides training for an industry that is consistently growing.

Festo is also a Platinum sponsor of the WorldSkills Competition, where students from around the world compete to show off their skills in various fields of manufacturing and engineering technology, like mechatronics and industrial control, to name just a few.

Festo Didactic and WorldSkills: inspiring technical education around the world

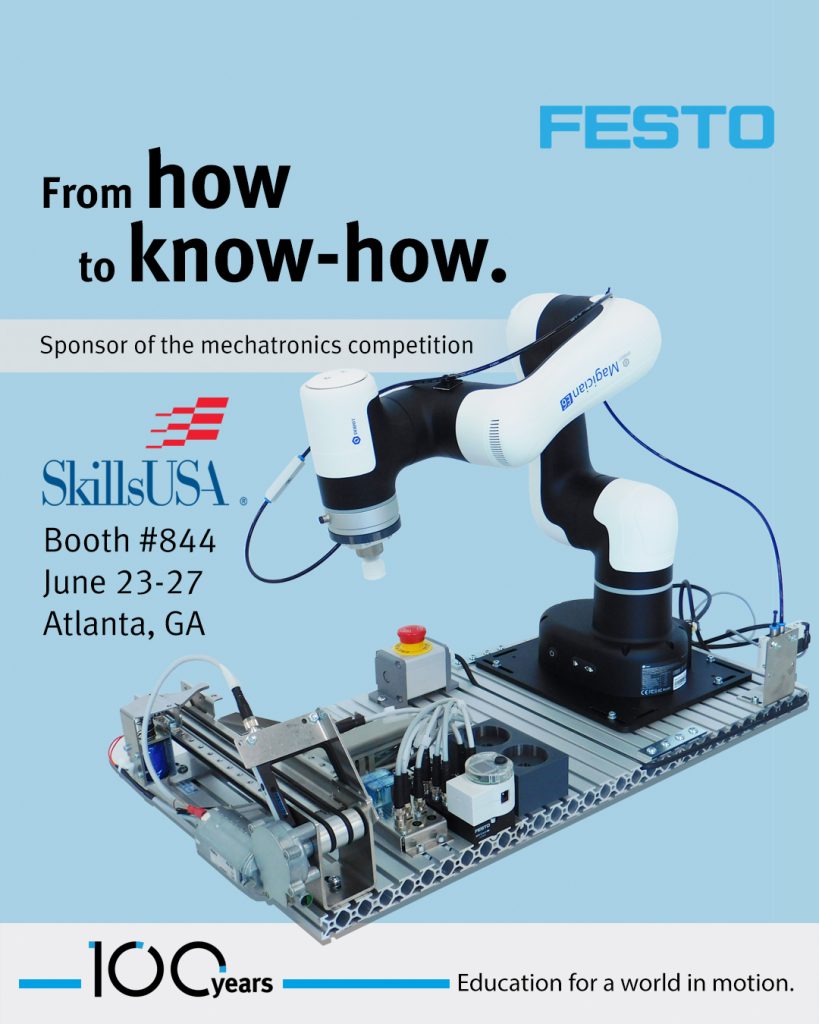

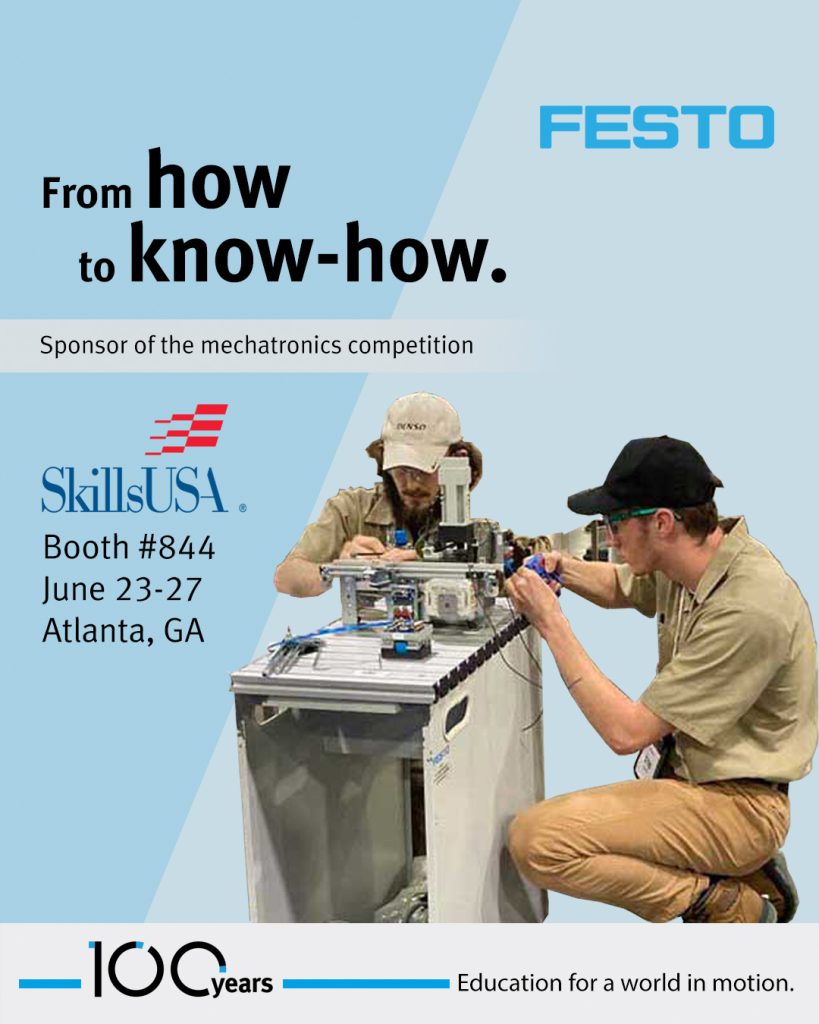

As part of their sponsorship of WorldSkills, Festo participates with SkillsCanada and Skills USA in North America. For Skills USA 2025, Festo sponsors the mechatronics competition for two groups of students: 17 teams of secondary students and 15 teams of post-secondary students.

Rodriguez explains how the different student groups will compete to demonstrate their skills. “The secondary group uses a product called the ‘MecLab,” which is a mechatronics training platform – and that is where we are partnering with Dobot. And the post-secondary group uses something called the ‘Skills Conveyor,’ which is a mechatronic system where the students build an entire automated platform.”

The SkillsUSA 2025 competition takes place between June 23 and 27, and winners will move on to compete at the WorldSkills 2026 in Shanghai, China.

Rodgriguez did not discuss the specifics of what the students in the mechatronics competition would be doing at SkillsUSA because that was kept secret until the event. But he does give a few insights into some of the tasks that students will perform. “There is a written exam where they have to prove certain knowledge points. And then we give them a task or a problem to solve, and they have to follow wiring schematics and create a program to automate a task.”

Rodriguez explains that to create a mechatronic platform, students integrate a lot of Festo’s products (Festo has a broad portfolio of automation solutions such as pneumatics, actuators, cylinders, and controls) but they will also integrate products from other vendors. Students need to be able to demonstrate that they have the skills needed to work in the industry, and there are many manufacturers that support the industry. “Our inclusion of Dobot, for example, who has a collaborative robot that we are using [in the competition], is a demonstration of how we collaborate with partners in this field,” he says.

Partnerships with Dobot and NC3 at Skills USA 2025

There are hundreds of robot companies around the world, and Rodriguez says that Festo works with all the big ones: FANUC, Universal Robots, Denso, and more. “Those are large, industrial-grade robots. And we have platforms where we use those in our training factories,” he says. “Dobot is a relatively new company from China that has a range of robots. This [robot used in the competition] is not their smallest. This is the third or fourth in a series of robots, from very small, handheld robots to large industrial robots.” he says.

“We chose Dobot because they fit right into that space or segment of the market where we need a low cost but highly functional collaborative robot,” explains Rodriguez. “And collaborative robots are a little different from normal robots [industrial robots] in that they are equipped with certain sensor technology that allows them to share a space with a human without hurting them. And we are starting to see more and more of that applied to industry. They have been great partners. They are providing the robot that we will use in the competition, and they will also be one of the judges.”

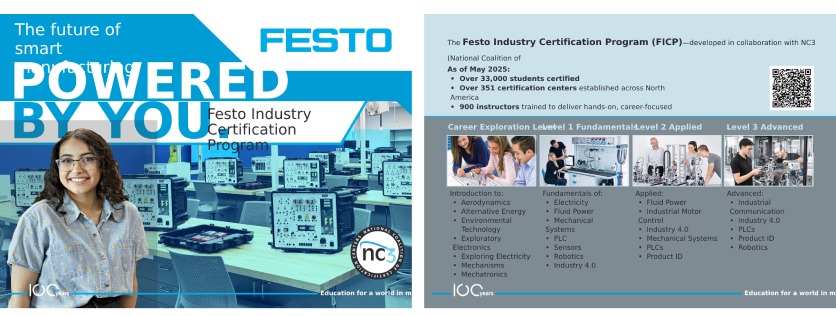

For Skills USA, Festo is also partnering with NC3, the National Coalition of Certification Centres. NC3 is on a mission to establish the future of career and technical education by creating highly skilled, job-ready professionals through a network of educational partners and global industry leaders.

Rodriguez says that part of Festo’s partnership with NC3 is on the certification side. “You want to make sure that when you are training someone to perform a task or demonstrate a skill, that you can assess that competency and assure an employer that the student possesses that skill,” he says. “NC3 provides a testing platform for testing skills and knowledge that utilize our curriculum in our training systems. We have about 27 or more industrial certifications that are certified by NC3.”

The other part of Festo’s partnership with NC3 is on the industry side, where they provide insights into the workforce. “Not only is Festo an industry partner, but there are probably 17 or 18 other well-known companies like 3M, Trane, and Lincoln Electric. Companies that are well known in the industry, who also have their own certifications and are a part of that coalition,” Rodriguez says. They are rooted in America but are expanding internationally to support education and industry as companies around the world grapple with skilled worker shortages and reshoring trends.

Rodriguez says that NC3 has a presence in Canada at certain educational institutions and are looking to expand into other areas as well, particularly Mexico. “They are expanding internationally: they have initiatives in Jamaica and Morocco. There is a desire to expand to places like Mexico,” he says. “We are finding that industry is very agnostic about where it is located. We are seeing industry come back to the United States, we are seeing reshoring, non-shoring. And border zone companies, for example, in Mexico, they are filling up with companies from all over the world. So, being able to provide a certification vehicle for those companies is very important, so Mexico is probably the next target.”

Technical training for industry. For today. And for tomorrow

We are living in transformative times. Innovation has always existed; and it is always moving forward. “The onset of electrification in this country [USA] has created a crisis. That has always been there. But now this is coupled with a few other factors. An aging population: we are finding a lot of retirements that are reducing the size of the workforce. The onshoring and reshoring phenomenon: that is a global issue,” Rodriguez says. “We see industries coming here to this country, but they are also going to Mexico. They are going to Peru. Industries are less and less driven by cost than they are by talent.”

Securing a skilled workforce for the future is a big priority, and Festo is actively working to create a supply of skilled workers for the companies that need them, where they need them. Industries such as automotive manufacturing, electric vehicles in particular, semiconductor manufacturing, pharmaceuticals manufacturing, and renewable energy are all areas where Festo is actively participating in building a pipeline of educated, skilled workers. “All these elements, they create a whole different requirement for training, and an extended requirement for training. So, we are producing those products at a much faster pace,” Rodriguez says. “Those are some of the exciting things in terms of the innovation we are applying to keep up with those changing needs.”

Educating the workforce of the future is important. But so is supporting the existing workforce with lifelong learning as technologies advance and new ones emerge. “Industry’s incumbent workers need training as well. And that is a need that we are addressing through our industrial workforce development division,” Rodriguez says.

“We can go into a company and set up an apprenticeship program. The hardest thing about business today is hiring and retaining workers. So, one of the ways we retain them is to train them to be effective in their jobs. That is a big need in the industry.”

Hands-on learning? It is all about hands-on learning!

Rodriguez says they are very enthusiastic about these opportunities and approach them with the same zeal as the founders of Festo did a century ago. And he hopes the effect they have had on the industry over the last 100 years will be reflected for the next 100 years. Festo’s hands-on training is a key to this success. “I think that what differentiates us from our competitors is the quality of our curriculum and the learning management systems that we have – whether it is a paper-based or a digital learning management system. The hands-on element is very important.”

Festo’s learning systems cover a plethora of areas, from fluid power to process automation to electricity and electronics and more. Rodriguez says their simulations are a bridge between the theory and the hands-on elements necessary to gain competency in a skill. “We can simulate a fluid power circuit in a learning environment, and we can apply that knowledge where they use the simulator. They learn the theory, and now they are applying it with a real system, with a piece of hardware. They are connecting real hoses and applying real power to something,” Rodriguez says. “It is a transition between knowing nothing and being able to demystify a technology and be comfortable with what they will see on the plant floor. Most of what we sell right now is hands-on or has a hands-on element.”

“Cer-tif-i-cate”: an official document attesting a certain fact

The quality of learning matters. “A certificate is only as valuable as the platform it was developed on,” Rodriguez says. “When we say you are a fluid power certified pneumatic specialist, or understand alternating current and direct current, it is because we put you through a piece of equipment where you demonstrated those skills. It does increase employability, and that recognition is starting to be much more visible in the market with groups like NC3.”

Through NC3 certification, Festo has issued over 30,000 certifications, which are free for students to earn, provided their school instructor has been trained by NC3. Moreover, Festo Didactic also offers 36 different types of certifications with 12 more in development. Students are earning certifications before they graduate, and employers are offering them jobs before they graduate. Sometimes, right out of high school.

“We had a student in Arizona, in a high school program, and they went through Festo’s metrology program. And they were hired right out of high school,” Rodriguez says. “The demand for those skills is outpacing the supply. Companies are going in and making very good offers to these students. Hopefully, through things like micro certifications, they can continue their studies and stackable certifications. That is another term you will hear in this new age of learning.”

Rodriguez says that in this new age of learning earning a degree is not necessarily achieved by sitting in a seat for four years or two years at a college. It can be achieved by stacking different certifications, one on top of another. “We do that in our learning profiles. If you look at how we design a mechatronics curriculum, for example, you can stack multiple certifications to achieve that ultimate goal.”

More Information

Interested in learning more about Festo’s technical training or their partnership with NC3 or their involvement in WorldSkills? Visit their website or reach out to them today.

Related Story

Festo Didactic Showcases Technical Education and Training at Hannover Messe 2025

Hannover Messe 2025 was an extra special event for Festo. The Festo Group celebrated their 100th anniversary, Festo Canada celebrated their 50th anniversary, and Festo Didactic celebrated their 60th anniversary. Festo Didactic, the education arm of the company, understands how important education is for empowering individuals, driving economic growth, and promoting social progress.