EtherCAT Plug-in Modules and Measurement Terminals in Test System for Batteries and Power Electronics

June 5, 2025

Modular, compact, and flexible for minimized development and testing times

Baumann GmbH, Amberg, develops turnkey automation systems for the automotive supply industry and electronics, pharmaceutical, and medical technology industries, as well as other sectors. These systems range from robot cells to fully automated production lines. The product range includes the MTS (Modular Test System), a flexible way to implement test applications for cell, module and battery test benches as well as for power electronics and more. PC-based control from Beckhoff provides the basis for compact design and system openness, in particular with the EtherCAT plug-in modules from the EJ series and the EtherCAT measurement terminals from the ELM series.

Baumann has been relying on PC-based and EtherCAT-based control technology from Beckhoff for its test systems since 2005 already. According to Jörg Seybold, Head of Standard Solutions and Products at Baumann, the decisive factor in this choice was not simply the performance, but the system’s variety of interfaces and openness – useful both for integrating a wide range of measuring devices and for communicating with higher-level systems and the Internet.

Specific requirements for automotive test systems

Electromobility is currently not only fundamentally changing production technology in the automotive sector, but also the required testing technology. Jörg Seybold explains: “Whereas in the past, it took several years to develop a new product in the automotive industry, we are now seeing continuous development in battery technology with product changes occurring every quarter. That means we need to develop a test system for customers that is modular, scalable, and easy to adapt to new requirements. The result is the MTS, which provides a complete test system within a compact control cabinet, meaning it can be used to replace conventional systems with up to five control cabinets.”

In addition to the small footprint, the MTS benefits the user through significant time savings: For new applications, the test system no longer has to be converted over a period of several weeks. The modular design with 19-inch slide-in units and plug-and-play functionality enables a quick and flexible response to changes – often by the end users themselves and without Baumann’s involvement. “The measurement scope is immense, with amperes ranging from micro-amperes up to several 100 A. The same applies to the variety of voltages, from 4.2 V cell voltage measurement to testing in the 1,000 V range, e.g., for complete truck battery storage systems,” explains Jörg Seybold.

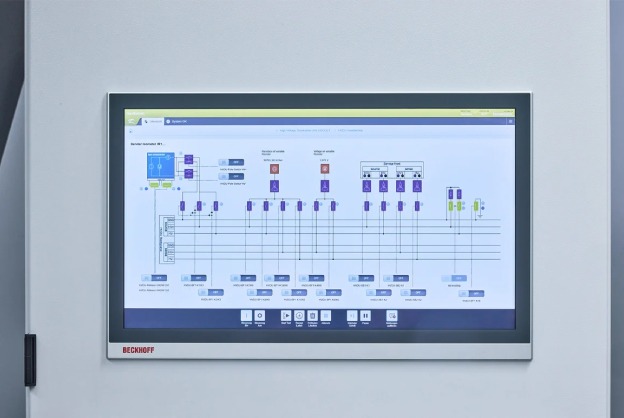

This is implemented in the MTS with the two basic modules CCU (Control & Communication Unit) and PDU (Power Distribution Unit), as well as with the MDU (Measurement Distribution Unit), HVDU (High Voltage Distribution Unit), and HCDU (High Current Distribution Unit) components, which can be selected as required. Added to this is a test framework that users can easily adapt to their individual test recipes and sequences and operate conveniently via the CP2924 multi-touch built-in Control Panel from Beckhoff. The framework offers graphical diagnostic and analytic functions, standardized data interfaces to MES systems, process monitoring, and more.

Control technology with compact, powerful I/Os

The complete MTS control technology and the Baumann test framework run on a C6032 ultra-compact Industrial PC with TwinCAT 3 software. Heiko Hochmuth, Head of Development for Measurement and Test Technology at Baumann, explains: “The main advantages of the C6032 are the small installation space required and the flexible mounting options. With the MTS, it often comes down to the millimeter.” And his colleague Martin Lehmeier, Team Leader for Software Test Systems, adds: “With regard to the software, TwinCAT 3 gives us a number of benefits, including the powerful debugging and the wide range of functions. Also the very diverse programming options, including in high-level language, because without this, our test framework based on it would not have been possible.”

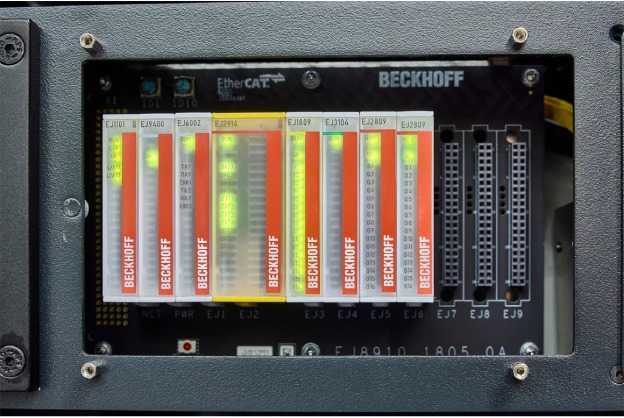

The use of EtherCAT plug-in modules from the EJ series offers Baumann significant advantages, as Heiko Hochmuth explains: “Mounted on the customer-specific signal distribution board, the EJ modules can be used to create a very compact I/O level. Secondly, they eliminate the need for complex wiring, which means that wiring errors and the associated troubleshooting are avoided and costs are reduced. For all MTS modules, we use the same signal distribution board, which is appropriately equipped for each use case.

This simplifies warehousing while maintaining the necessary flexibility.” Furthermore, in contrast to a solution with EtherCAT Terminals, he adds that cable channels are no longer required, which contributes to the compact design of the overall system. According to Hochmuth, the flexibility of PC-based control is demonstrated not least by the variety of EtherCAT plug-in modules used in the MTS, such as:

- EJ1101-0022 EtherCAT Coupler,

- EJ1809 16-channel digital input modules,

- EJ1859 combination modules with eight digital inputs and eight digital outputs,

- EJ2809 16-channel digital output modules,

- EJ3104 (4-channel, ±10 V) and EJ3202 (2-channel, RTD) analog input modules,

- EJ1904 (4-channel digital input) and EJ2914 (4-channel digital output) TwinSAFE modules and

- EJ6002 2-channel communication interfaces (RS232/RS422/RS485).

According to Heiko Hochmuth, another major advantage of the wide Beckhoff I/O portfolio is the highly precise measurement terminals from the ELM series: “With the MTS, we primarily use the ELM voltage measurement terminals, which can be chosen to suit the respective application – with galvanic isolation, up to four analog inputs, and different voltage ranges up to ±1,200 V. The wide range of functions and measurement variables of the ELM terminals helps us a lot.

Added to this is the high measurement precision, including high temperature stability, as well as flexible data pre-processing via selectable additional parameters. And this high level of functionality is housed in a highly compact form factor and can replace previously separate measurement devices to save space and costs, which certainly makes the measurement technician’s heart beat faster.” Connected via the EKM1101 EtherCAT Coupler with ID switch and diagnostics, the following measurement terminals are used with the MTS, among others:

- ELM3002-0000 (2-channel) for flexible voltage measurement from 20 mV to 30 V in eleven measuring ranges,

- ELM3002-0205 (2-channel) for high-voltage measurement on batteries and generators in the measurement ranges ±60, 360, 600, and 1,200 V,

- ELM3004-0000 (4-channel) for flexible voltage measurement from 20 mV to 30 V in eleven measuring ranges and

- ELM3102-0100 (2-channel) for voltage and current measurement in the measuring ranges +60 V to -20 mV and ±20 mA with a fast sampling rate of 20 ksps per channel.

This compact I/O level is supplemented as required by various EtherCAT Terminals from the EL series. In particular, this includes the EL3443 3-channel analog input terminal for power measurement (max. 480 V AC/DC, 1 A). It can be used to measure the values of current and voltage, as well as active, reactive, and apparent power or energy, together with cos φ, frequency, THD, and harmonics (up to the 40th harmonic). With the MTS, the EL3443 enables detailed monitoring of the grid feed-in.

More Information

- High-performance automation solutions for the automotive industry

- EtherCAT plug-in modules

- EtherCAT measurement terminals

- Baumann GmbH

Related Story

EtherCAT in Boost Mode

EtherCAT is by far the fastest Industrial Ethernet technology. Nevertheless, the data acquisition process at Kraus & Naimer’s cam controller test benches called for an even shorter bus cycle. To achieve the required performance, Beckhoff specialists reduced the previous cycle time from 100 µs to 20 µs.