Endress+Hauser W.I.N. Initiative Promotes Diversity, Inclusion of Women, Minorities

June 1, 2021

Endress+Hauser Group, in keeping with its role as global leader in measurement instrumentation, is conducting an employee-led program to increase the participation of women at all levels in the company. At Endress+Hauser entities around the world, committees have been struck under the banner of Women’s Integrated Network (W.I.N.) to undertake measures to increase female representation throughout the workforce. Recruiting and promoting women will help sustain the exceptional innovative and entrepreneurial capacity of the company and ensure its continued success, while promoting STEM careers to young women.

In Canada’s case, the W.I.N. initiative has a unique opportunity, since female representation in Endress+Hauser Canada essentially meets the targets for 2030 set by Endress+Hauser Group’s Executive Board. This will allow the Canadian program to align its goals in a manner that reflects the country’s unique demographic makeup.

“From a global perspective, the W.I.N. program is focussing primarily on increasing female involvement and leadership in the company, whereas we in Canada want female empowerment, but also to increase the inclusiveness and diversity of our team,” says Dr. Zoe Reeve, chairperson of the Canadian W.I.N. committee, which includes women and men from across the country. “Our work will be sensitive to gender issues, but not be solely about gender. We want to nurture a corporate culture where it doesn’t matter which gender, race or ethnicity you are, you will feel comfortable about joining and engaging with the rest of the team.”

Corporately, the goal is to roughly double the percentage of women in the global workforce to about 40%, of whom 28-30% will be in leadership positions (up from 17% now). That increased presence should include technical and other specialized roles. In Canada, women comprise 36% of staff and hold 41% of leadership positions. The Canadian program will devote part of its resources to eliminating embedded biases in hiring, training and promotion and to develop a mentorship program to help employees overcome their reticence to champion ideas or embrace leadership roles and even advancement opportunities. “A lot of people want to develop and grow in their career but they really don’t know how to,” says Reeve. “And they don’t know what options are available. That’s what the mentorship program will address.”

External components include changing the company’s branding to better reflect diversity, and to help STEM students expand their understanding of what the company can offer them.

Some of the program elements require an in-person presence and have been delayed by the Covid-19 pandemic. That includes outreach to young people at universities, colleges and technical schools, and visits by students to Endress+Hauser Canada facilities. “We want to engage with women and by reaching out to them as students,” says Reeve, a PhD chemist and Endress+Hauser Canada’s only female product manager (analytical instruments). Such get-togethers can inform them of opportunities in STEM that they might not have imagined. “When I was in school,” adds Reeve, “I didn’t realize that there were technical marketing jobs that I could do with a chemistry degree. I really love what I do, but it’s not something I would have picked five years ago because I didn’t know it existed.”

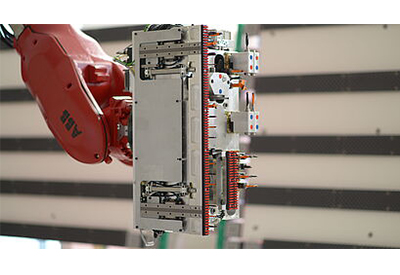

Those in-person activities should ramp up this fall assuming pandemic restrictions ease, and especially when the company opens its new 47,000 sq ft Customer Experience Centre in Burlington, ON. That centre features a state-of-the-art Process Training Unit, world class calibration laboratory and other advanced features.

For more information, visit www.ca.endress.com.