Efficient Power Monitoring at the Edge: Moxa’s DCI Solutions for Data Centres

December 17, 2025

As data centres grow in higher densities to support AI-enabled workloads and more complicated operations, keeping the Power Usage Effectiveness (PUE) at optimum is critical at this time. Downtime is never acceptable. Also, without being able to see electrical systems in real-time, such as substations, UPS, switchgear, and HVAC, failures will take place, and reaction times will be delayed.

Newer generation data facilities will face more and more constant pressure to maintain low PUE alongside the increasing pressures of power consumption. Continuity of power depends on smart and resilient connectivity across data center infrastructure (DCI). All energy systems need to operate in concert for continuous operations.

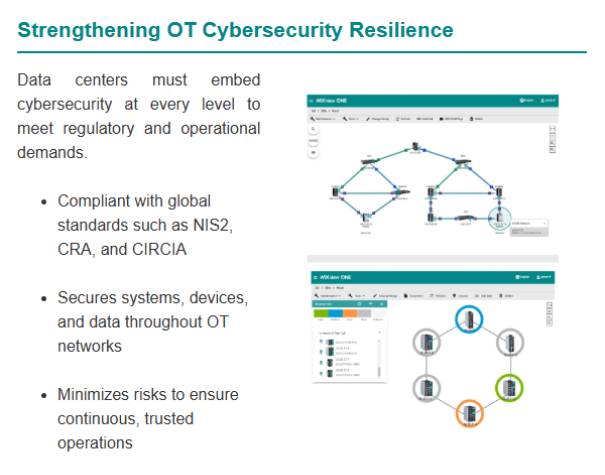

Moxa industrial-grade networking solutions keep data center power systems connected, efficient, and secured through reliable, secure, and scalable communications. Engineers can download the solution guide and success case for more information, or meet with a solution expert to receive customized recommendations.

Why Choose Moxa Industrial Connectivity and Networking Solutions

Reliable DCI Connectivity for Power Monitoring Applications

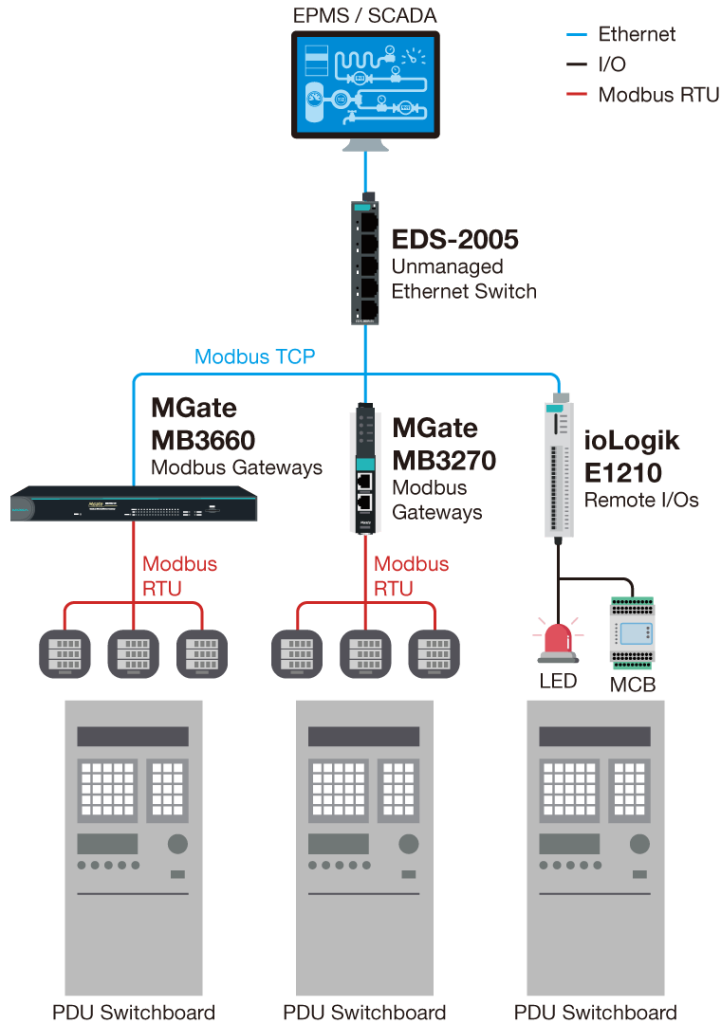

1. PDU Monitoring Networks

For effective monitoring and control of Power Distribution Units (PDUs), Moxa delivers integrated connectivity that streamlines data flow from PDUs and Static Transfer Switches (STS) into EPMS and SCADA systems.

Requirements

- Remote access for PDU status and control

- Transparent protocol conversion from Modbus RTU to Modbus TCP

- Digital input data collection

- Serial connectivity using RJ45 connectors

Why Moxa

- A comprehensive product portfolio: MGate MB3270 and MB3660 protocol gateways (2-port and 16-port options) convert Modbus RTU to Modbus TCP; ioLogik E1210 remote I/O delivers I/O signals, and the unmanaged switch EDS-2000 Series ensures stable, EMI-resistant Ethernet communication.

- High-density, high-performance Modbus protocol conversion

- Intuitive, easy-to-use configuration interface

- Built-in diagnostic tools for efficient troubleshooting

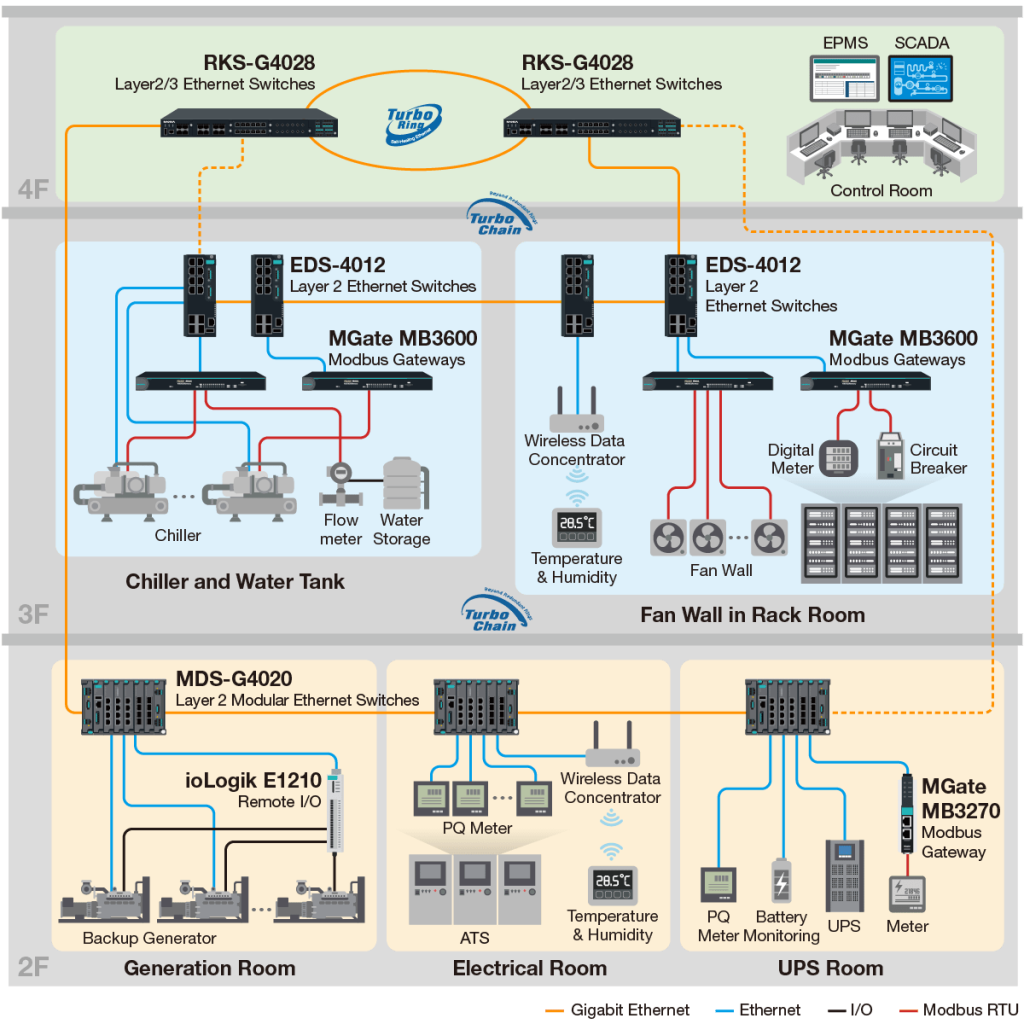

2. EPMS/SCADA Systems Networks

To ensure peak availability, Moxa provides a unified networking infrastructure that integrates EPMS and SCADA communications. This architecture enables reliable connectivity, fast data acquisition, and seamless monitoring of electrical power, cooling, and environmental systems throughout the facility.

Requirements

- Achieve five 9’s (99.999%) system availability

- Integrated communications across LV/MV switch room, cooling, and other facility operation systems

- Collect and transmit large volumes of data from a variety of power and cooling monitoring devices and sensors

Why Moxa

- No annual licensing fees. Avoid hidden costs and reduce operation expense.

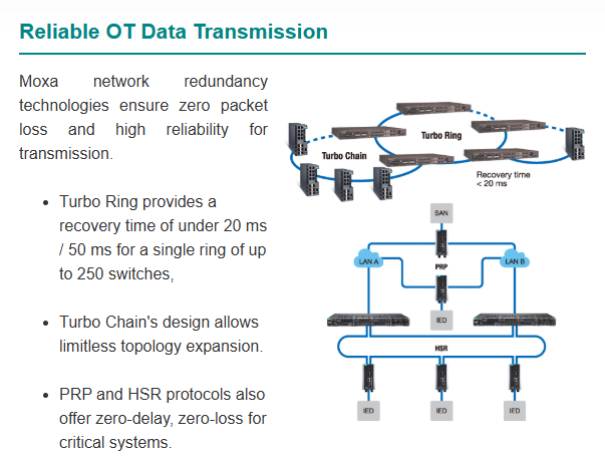

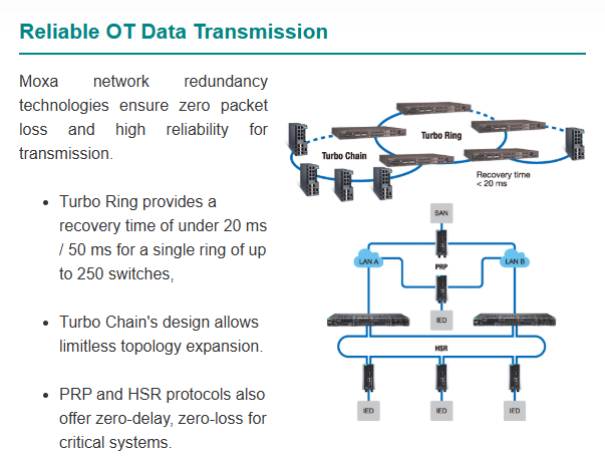

- Scalable and reliable network architecture with Turbo Ring and Turbo Chain redundancy technologies, supporting millisecond-level network recovery (up to 250 switches)

- A comprehensive product portfolio from Modbus gateways, managed Ethernet switches to remote I/O

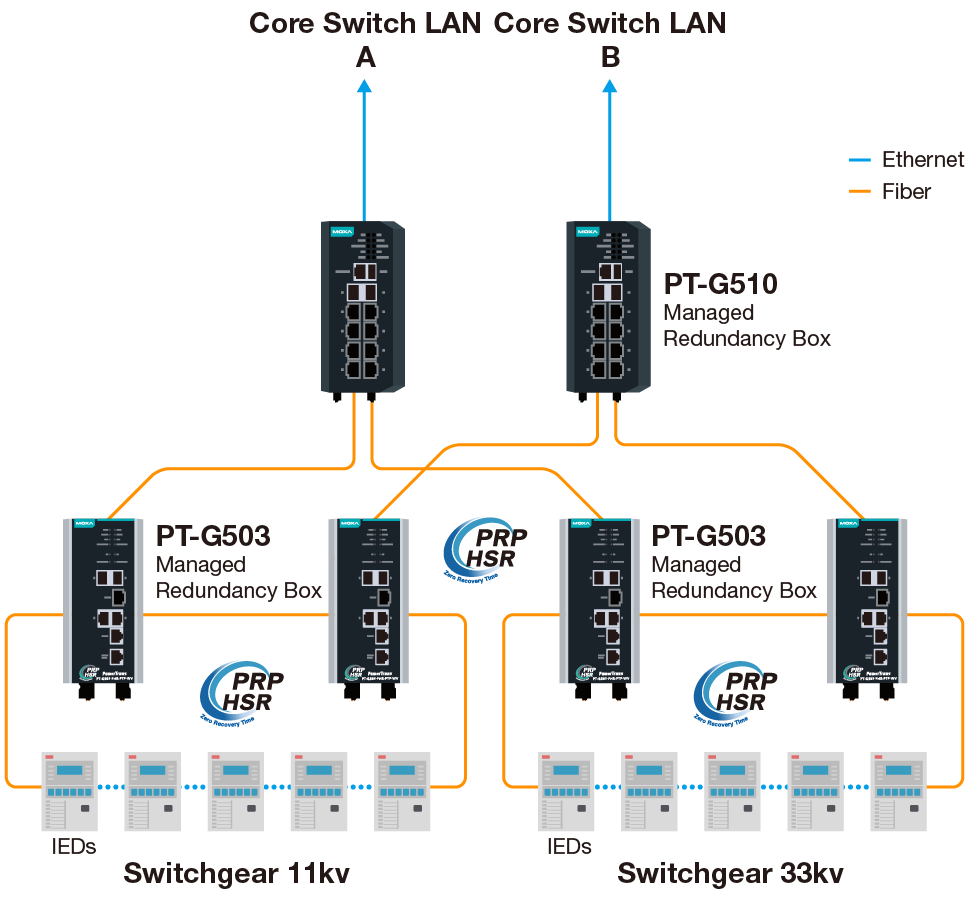

3. HSR Networks for Medium-Voltage Switchgear

H High-availability Seamless Redundancy (HSR) topology ensures zero recovery time for data center power delivery, making it ideal for MV switchgear environments. This design provides redundant, high-speed connectivity for Intelligent Electronic Devices (IEDs) while supporting protection, monitoring, and integration into the broader DCI network.

Requirements

- IEDs to support MV switchgear protection

- High-availability, redundant networks for data center infrastructure

- HSR topology implementation for MV switchgear to connect with the DCI network backbone

Why Moxa

- A wide range of IEC 61850-3 certified Ethernet switches designed for HV/MV power applications

- Professional network consultation services for network designs; technical support for PoC

More Information

*For any further information, please contact them via sales@manuauto.com.

Related Story

Smarter Power System Monitoring with Moxa Easy-to-Use Protocol Gateways

In industrial settings, effective power system monitoring plays a vital role in ensuring operational efficiency. It involves the real-time tracking of power quality, energy consumption, and equipment conditions. However, due to the varied nature of power grids, often composed of multiple energy sources and communication protocols, designing a unified power monitoring solution can be complex. Moxa addresses this challenge with an extensive selection of protocol gateways, engineered to deliver dependable, secure, and intuitive connectivity for numerous applications.