25 Advanced Motion Control Questions Answered

October 1, 2025

Electromate has compiled a list of 25 advanced mechatronic engineering FAQs covering inertia, vibration, servo safety, control tuning, encoder resolution, and motion system design, and provided answers from their team of experts across the country.

How do I model moment loading in real-world applications with offset payloads?

Moment loading should be calculated as the product of load force and its perpendicular distance from the rotation axis. Account for compound moments in cantilevered arms or offset grippers. Validate bearing life and guide rail stress against combined loading conditions.

In high-dynamic linear stages, how can I minimize failure caused by unaccounted moment loads?

Use guide systems rated for combined forces and moments, and analyze the moment center relative to the drive point. Overlooking offset loads leads to misalignment, guide wear, and reduced positioning accuracy under load transitions.

How do I select bearing systems to optimize load handling and reduce frictional losses in high-cycle automation?

Choose bearing types (e.g., linear guides, crossed roller, or air bearings) based on load orientation, stiffness needs, and duty cycle. Minimize preload to reduce friction unless backlash elimination is critical. Monitor for brinelling in high-shock systems.

In servo-driven mechanisms, how do I mitigate torsional compliance caused by mechanical couplings?

Select high-stiffness couplings (disc or bellows types) and validate torsional spring constants against required loop bandwidth. Avoid elastomeric types in closed-loop applications where responsiveness and rigidity are critical.

How do I apply inertia matching for multi-axis motion platforms with varying load profiles?

Target a load-to-motor inertia ratio between 1:1 and 5:1 per axis. For axes with variable payloads (e.g., Z-axis with tool changers), use gearing or counterbalancing. Always model reflected inertia using real profiles—not static loads.

What is the practical impact of high inertia mismatch in interpolated servo axes?

Excess mismatch leads to overshoot, instability, and control lag, especially in coordinated motion. Use velocity feedforward, gain scheduling, or active damping only after mechanical solutions (gearing or load reduction) are exhausted.

When integrating servo brakes on vertical axes, what are the system-level safety requirements during a power-off event?

Use spring-engaged, power-off brakes sized with a 1.5–2.0 safety factor. The brake must engage within milliseconds of STO (Safe Torque Off) signal and hold the full static load without drift. Test under simulated fault conditions.

How does gear ratio selection impact both performance and mechanical resonance in high-speed applications?

While increasing gear ratio reduces reflected inertia and allows a smaller motor, it can introduce compliance and amplify backlash. Select precision gearheads with low torsional wind-up and account for added phase lag in control tuning.

How do I differentiate and mitigate structural versus control-loop sources of vibration in servo systems?

Use frequency analysis (FFT) to isolate mechanical resonance (typically narrowband) from control loop instability (broader bandwidth). Apply notch filters for structural modes and retune loop gains to avoid amplification. Reinforce weak mechanical interfaces.

In high-acceleration profiles, how do I manage dynamic loading without exceeding thermal limits of the motor?

Calculate peak torque for acceleration phases and RMS torque for thermal modeling. Validate duty cycle against motor continuous rating. Use aluminum framing or forced-air cooling if thermal derating limits performance.

What techniques reduce overshoot and oscillation in S-curve motion profiles for high-inertia loads?

Tune jerk parameters and extend the transition duration between acceleration phases. Combine this with feedforward control to anticipate torque demands. Use high-resolution encoders for better velocity estimation.

How do I implement homing routines on absolute-encoded multi-axis platforms where mechanical offsets vary by axis?

Use absolute encoders for initial power-up referencing, but apply dynamic offset correction routines for mechanical stack-up (e.g., from tool changers or gantry skew). Integrate offset storage into nonvolatile memory and apply during boot sequence.

In coordinated motion systems, how do I apply camming for asynchronous master-slave profiles?

Generate cam tables based on master position with corresponding target positions for the slave. Use spline or polynomial interpolation to avoid discontinuities. Recompute profiles dynamically if master speed varies due to load conditions.

How do I compensate for backlash in gearboxes during direction reversals in high-precision systems?

Use preloaded gear stages or dual motors in counter-torque configurations. At the control level, implement backlash compensation tables or deadband reversal logic. Do not rely solely on encoder feedback—compensate mechanically when possible.

In systems with regeneration, how do I size dynamic braking resistors to avoid overvoltage shutdowns?

Estimate regen energy from decelerated inertia and deceleration time. Select braking resistors to absorb peak energy and dissipate it within the resistor’s thermal envelope. Add thermal overload protection to prevent resistor failure during repeated stops.

How do I architect a motion I/O strategy to synchronize mechanical outputs with encoder positions?

Map encoder position thresholds to I/O trigger events using the motion controller’s event-based logic. Use deterministic buses (e.g., EtherCAT) for sub-millisecond reaction time. Validate all timing paths in high-speed inspection or cutting applications.

How does digital loop bandwidth influence closed-loop stiffness and control response in multi-axis systems?

Higher bandwidth increases stiffness and tracking accuracy but requires a rigid mechanical system. Use auto-tuning tools to set gain ratios appropriately and monitor phase margin to prevent instability across varying load conditions.

What encoder resolution is necessary to support sub-micron positioning in screw-driven linear systems?

Resolution depends on lead pitch and desired minimum move. For a 5 mm lead screw requiring 0.1 µm resolution, you need a system resolution of 50,000 counts per revolution or more. Use interpolated sin/cos encoders or high-line-count digital encoders.

What’s the role of motion sequence control in error handling and conditional logic for autonomous machinery?

Sequence control structures define not only the order of moves but also conditional responses to sensor input, alarms, or interrupts. Implement state machines with error recovery branches and safety state transitions for unattended cycles.

When does EtherCAT outperform traditional step/direction or analog interfaces in multi-axis control?

EtherCAT offers deterministic, sub-millisecond communication ideal for synchronized motion across multiple axes. It outperforms step/dir in coordinated motion and provides real-time diagnostics, remote I/O, and distributed clock synchronization.

How do I use S-curve profiles and gear reduction together to minimize vibration in high-speed pick-and-place axes?

Use S-curves to soften acceleration transitions and gear reduction to reduce motor load. Match gear ratio to balance reflected inertia and mechanical stiffness. Validate motion profile using real load to check for induced resonance at transitions.

What are the most effective methods to mitigate thermal drift in ballscrew-based systems with high-duty cycles?

Implement preloading and thermal expansion compensation algorithms. Use dual temperature sensors (motor and ambient) and linear encoders for closed-loop position verification. Apply symmetrical heating or force-air cooling to stabilize ambient effects.

How do you integrate functional safety into actuator-level design for IEC 61508 or ISO 13849 compliance?

Use STO-certified drives, spring-applied brakes, and redundant feedback sensors. Monitor actuator fault states and feedback error rates. Validate failure mode behavior during E-stop and power loss scenarios.

In systems using programmable camming, how do you validate profile accuracy under fluctuating master speeds?

Use real-time recalculation or dynamic cam compression logic. Validate with cycle simulation and encoder feedback capture. Tune slave loop gains for high responsiveness and avoid overshoot at speed discontinuities.

How should RMS torque be interpreted in high-speed systems with intermittent high loads?

RMS torque is used to model thermal load, not mechanical peak capacity. For systems with infrequent high peaks, ensure peak torque does not exceed motor specs, but size for RMS to avoid overheating over time.

Related Story

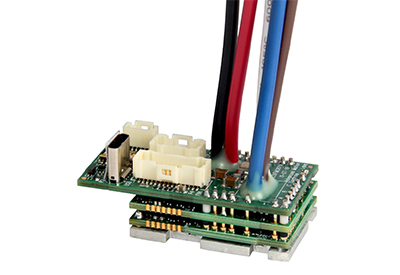

The Emergence of Mechatronic Subsystems and Their Importance in Product Deployment

As automation systems become more complex and project timelines compress, the role of mechatronic subsystems has shifted from convenience to a necessity for many OEMs. From modular robotic actuators to fully integrated motion systems, subsystem-level design is enabling manufacturers to accelerate development cycles, reduce risk, and concentrate internal resources on differentiation rather than reinvention.

In this Q&A, Warren Osak, President and Founder of Electromate, discusses the emergence of mechatronic subsystems, their impact on deployment timelines, and why more OEMs are adopting integrated solutions over traditional component sourcing.