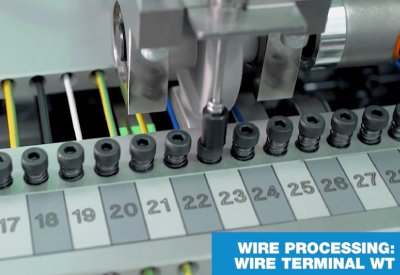

Overcoming Automation Challenges with Sysmac: Lessons from Real-World Applications

January 8, 2025

Modern manufacturing is riddled with challenges that demand innovative, reliable, and flexible solutions. From bridging knowledge gaps to reducing downtime, these hurdles can hold back productivity and profitability. The Sysmac automation platform from Omron addresses these pain points head-on, offering a comprehensive suite of components and features designed to streamline processes and enhance operational efficiency.

By examining real-world success stories, we can better understand how Sysmac tackles challenges faced by manufacturers across industries.

Addressing Manufacturing Pain Points

The Labor and Knowledge Gap

One company in the fishing gear industry faced significant challenges when its aging automation systems required upgrades. The complexity of their existing machines, combined with a lack of local technical expertise, created bottlenecks in production. By adopting Sysmac, their engineers standardized their spooling and molding machines under a single platform. With Sysmac’s user-friendly Integrated Development Environment (IDE) and adherence to IEC 61131 standards, the company quickly trained its staff and implemented modern solutions.

Downlod Omron Sysmac Studio Brochure

Downtime and Maintenance Costs

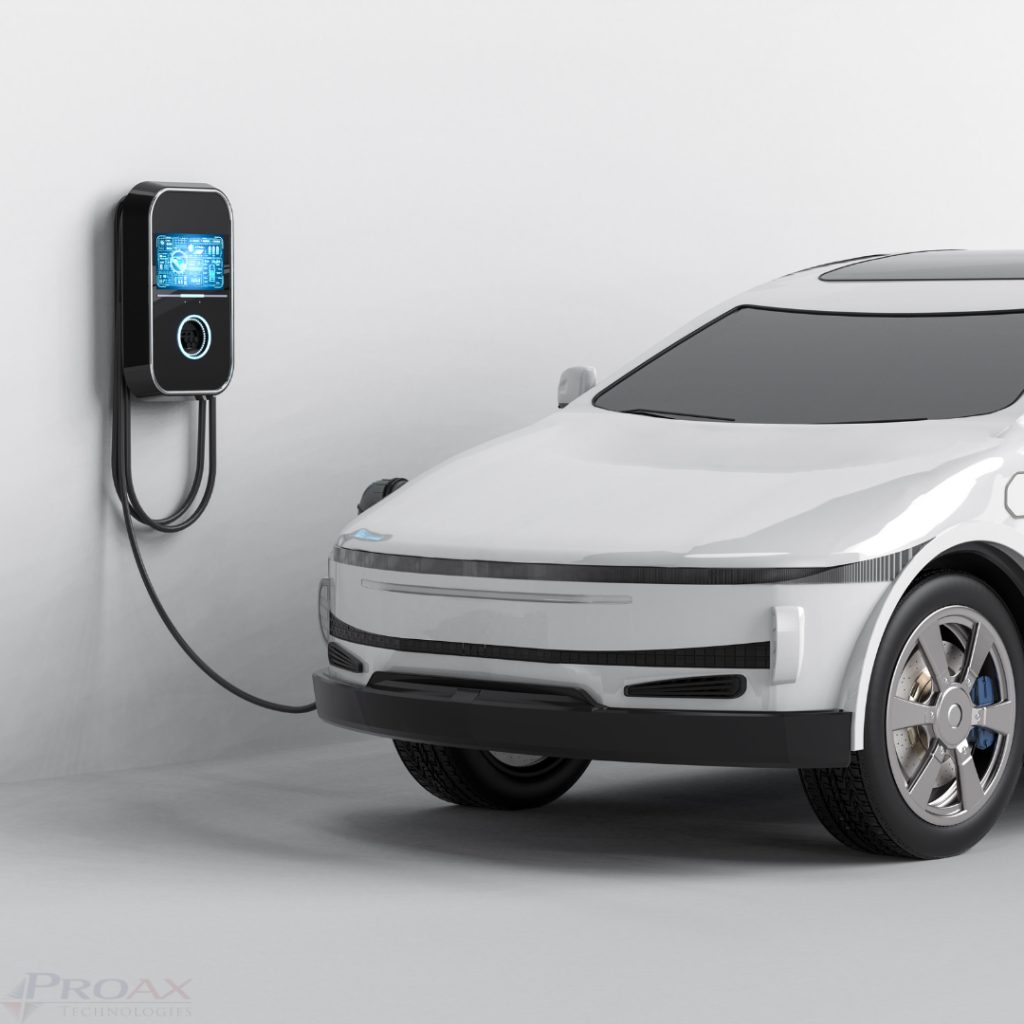

In the extrusion manufacturing industry, a company struggled with frequent downtime due to outdated controllers and incompatible software. Transitioning to Sysmac’s ecosystem, including CPUs like the NX502 and quick-replace sensors, allowed them to reduce downtime drastically. The platform’s automation playback and real-time monitoring provided tools to troubleshoot issues virtually, minimizing the need for prolonged maintenance stoppages.

Data Integration and Traceability

Another manufacturer in the food packaging industry needed advanced data traceability for regulatory compliance. By leveraging Sysmac’s support for industrial protocols like EtherNET/IP™ and EtherCAT®, they achieved seamless communication across all devices. Advanced data playback capabilities allowed their team to analyze production data and enhance first-pass yield, reducing overall waste.

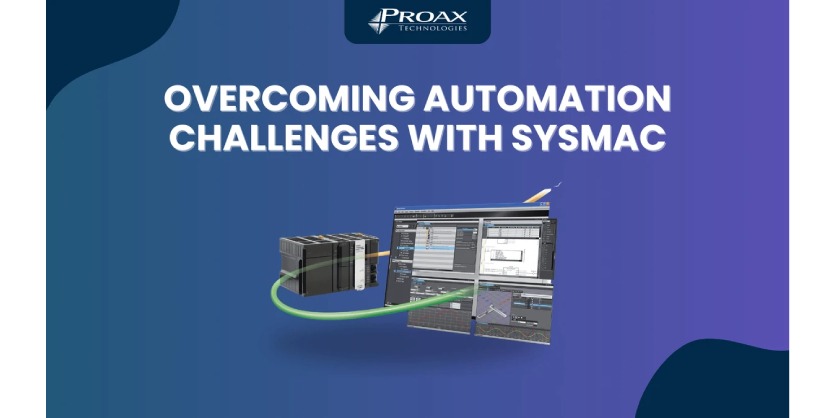

Breaking Down Sysmac’s Key Components

Integrated Development Environment (IDE)

Sysmac’s IDE is the cornerstone of its ecosystem, offering:

- Automation Playback: Virtually test and troubleshoot processes before deployment.

- Holistic Data Playback: Analyze and optimize production performance.

- Lifetime Access: Eliminate ongoing software licensing issues.

Explore Sysmac Studio Free for 30 Days

Try Sysmac Studio with a free 30-day trial. Experience 3D simulation, PLC logic, and HMI motion to optimize processes and reduce costs. Deploy faster with pre-written function blocks and seamless integration into your existing systems.

Try Sysmac Studio with a free 30-day trial

CPUs and Power Supplies

Modular CPUs like the NX102 and NX502 provide scalable processing power for diverse automation needs. Paired with power supplies such as the S8VK-G06024, Sysmac ensures stable operations in demanding environments.

Industrial PCs (IPC)

Omron’s IPCs, like the NYB6540530, support advanced analytics and third-party software while running Windows IoT 2021. These devices enable seamless integration into data-driven manufacturing environments.

Machine I/O & Safety

Sysmac integrates safety modules, coupler and machine I/O systems to ensure compliance and reliability during operation.

- Inspection and Traceability: Built-in tools enable quality assurance and real-time tracking of production processes.

- Local IO (e.g., NX-ID4442, NX-OD4256): Precise control and real-time data collection.

- Remote IO (e.g., NXR-ILM08C-ECT): Extend control capabilities across distributed systems.

- Safety IO (NX-SID800, NX-SOD400): Ensure regulatory compliance with reliability.

- Coupler (NX-ECC202): Integrate IO units with EtherCAT support seamlessly.

EtherCAT for Machine Control

The backbone of Sysmac’s machine control is EtherCAT connectivity, supporting:

- Multi-Axis Servo Control for high-precision automation tasks.

- Fixed Robots and Collaborative Robots to adapt to various industrial needs.

Sensing and Monitoring

Sysmac’s platform supports advanced sensors that collect real-time data for:

- AI on the Edge: Leveraging artificial intelligence directly on the factory floor to enhance predictive maintenance and analytics.

- Direct Monitoring: Ensures minimal downtime with instant alerts and system diagnostics.

Mobile and Collaborative Robots

Sysmac supports the integration of mobile robots and collaborative robots, creating flexible solutions for material handling and workflow optimization. A mobile robot fleet manager ensures efficient coordination between units.

Information and Factory Automation

- The platform bridges IT and OT seamlessly, connecting factory-floor devices to secure SQL databases for advanced analytics.

- It supports global industrial protocols such as OPC UA for universal compatibility.

Cables and Accessories

High-quality components like the XS5F-D421-D80-F cables provide secure, durable connections, ensuring long-term reliability.

Practical Benefits for Specific Industries

Electric Vehicle (EV) Manufacturing

- Brake Line Assembly: Improved synchronization between motion, vision, and safety systems.

- Battery Cell Production: Optimized temperature control for consistent throughput.

Food and Commodities (F&C)

- Sealer Solutions: Ensure product integrity with precise temperature control.

- High-Mix Low-Volume (HMLV): Adapt quickly to shifting consumer demands.

- Automated Material Changeover: Streamline processes to reduce downtime.

Insights from the Field

Simplifying Machine Upgrades

A company specializing in fishing gear modernized its operations by transitioning to Sysmac’s unified automation platform. This move allowed them to consolidate disparate systems into a single, scalable solution. The result? Improved uptime, simplified maintenance, and better overall performance.

Cutting Costs Without Sacrificing Quality

An extrusion equipment manufacturer replaced outdated control systems with Sysmac components. The streamlined configuration and enhanced compatibility significantly reduced their production costs while maintaining high-quality output.

Enhancing OEM Benchmarks

An OEM in the food packaging industry leveraged Sysmac to set new benchmarks for machine performance. By utilizing Sysmac’s advanced data capabilities and seamless integration, they achieved faster setup times, reduced waste, and improved overall equipment efficiency.

Sysmac’s Role in Common Manufacturing Challenges

- Reducing Downtime: Quick sensor replacement and automation playback eliminate delays.

- Streamlining Processes: Unified industrial protocols ensure seamless system integration.

- Enhancing Quality: Advanced traceability and real-time monitoring improve first-pass yield.

Why Proax + Sysmac Is Your Automation Partner

At Proax, they collaborate with Omron to deliver tailored Sysmac solutions that address your specific manufacturing challenges. Their approach combines:

- Expert Guidance: They assist with everything from component selection to deployment.

- Local Support: Enjoy faster response times and personalized assistance.

- Training and Resources: Equip your team to maximize Sysmac’s capabilities.

By pairing Omron’s Sysmac platform with Proax’s industry expertise, you gain a powerful ally in overcoming automation challenges and achieving operational excellence. Upgrade your automation with Omron’s Sysmac Bundles. Tailored for your needs, save up to 60% for limited time on safety, motion, and data solutions.

Related Story

Omron Honours Proax Technologies as 2022 Strategic Partner of the Year

Omron Automation Americas, a provider of industrial automation solutions, takes great pride in naming Proax Technologies as its Canadian Strategic Partner of the Year. This honor underlines Proax’s exceptional dedication and contribution to both Omron and its clientele over the previous year. As a leader in automation distribution, Proax has collaborated with Omron on numerous projects, earning its place as a reliable Canadian partner.