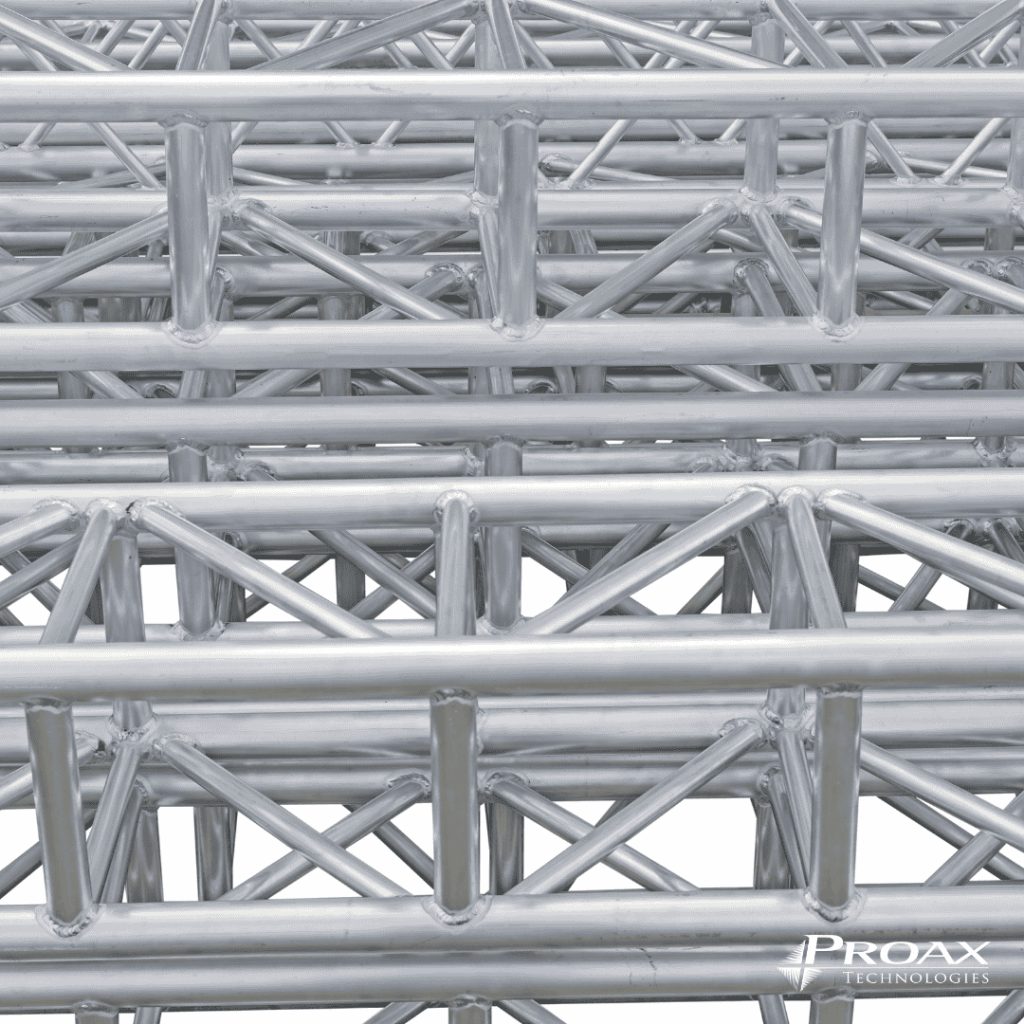

10 Most Common Applications of Aluminum Extrusions in Manufacturing

November 26, 2024

Discover how leading manufacturers are leveraging aluminum extrusions to enhance their production capabilities. This guide explores the most common applications of industrial aluminum profiles and precision extrusion systems in modern manufacturing.

1. Assembly Line Construction

The backbone of manufacturing operations relies on aluminum extrusions for:

- Modular T-slot framing for workstations

- Conveyor system frameworks

- Mounting solutions for production equipment

- Height-adjustable work surfaces

- Equipment support structures

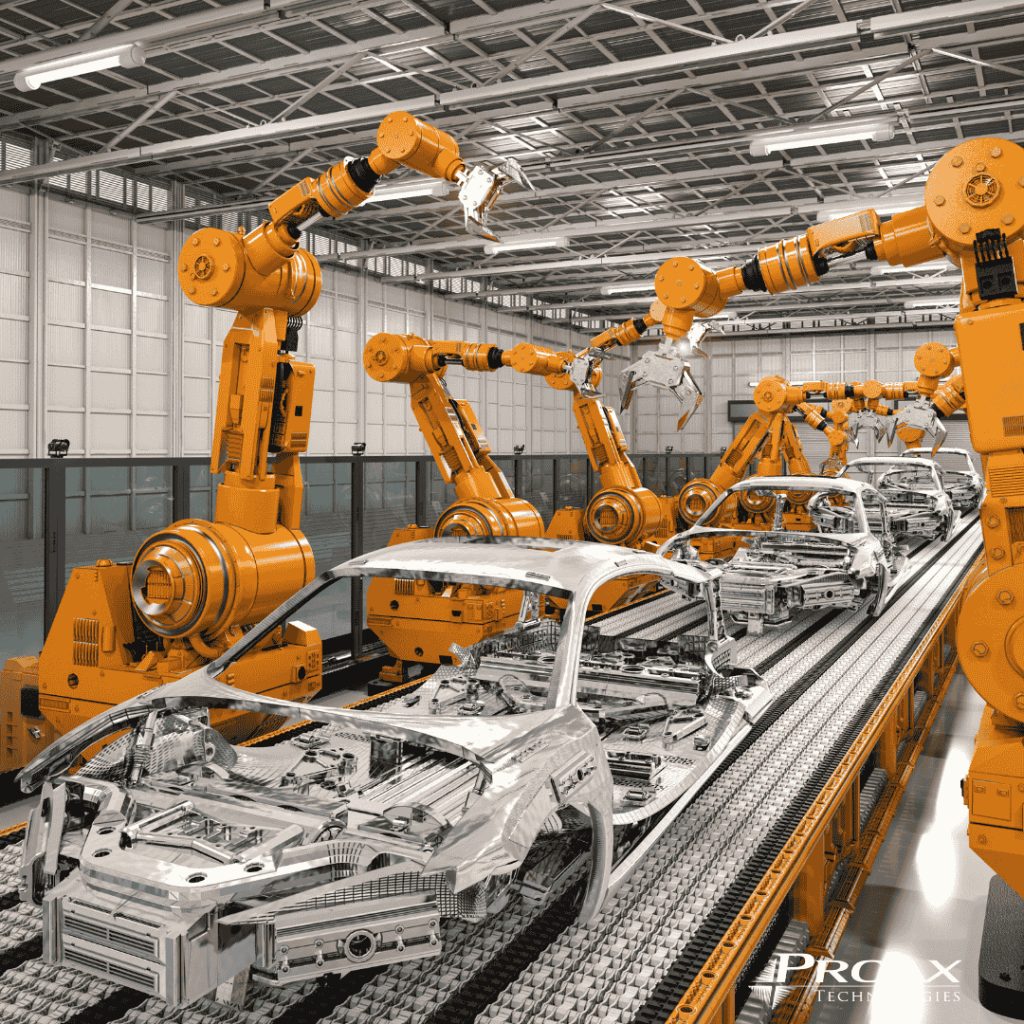

2. Automated Manufacturing Systems

Critical components in automation include:

- Robot mounting frameworks

- Linear motion system supports

- Guide rail mounting structures

- Sensor mounting brackets

- Control system frameworks

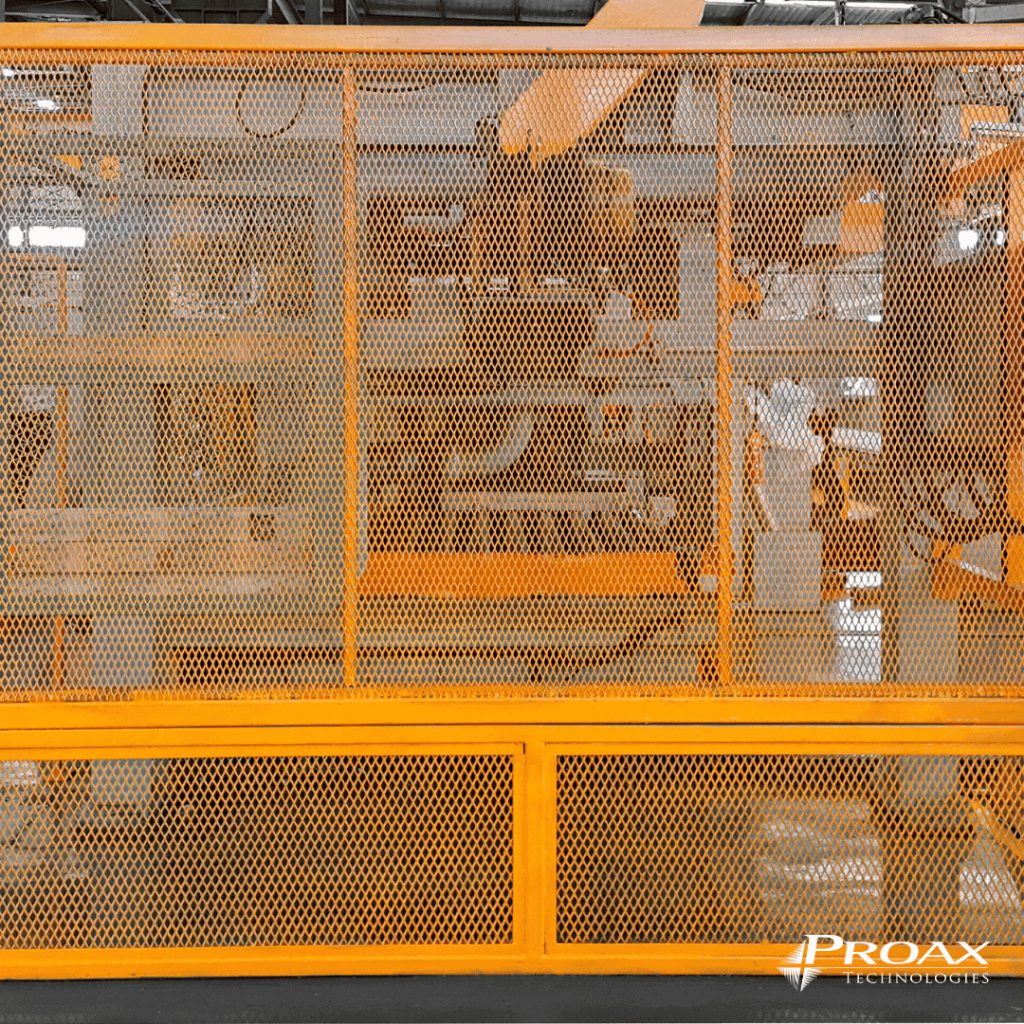

3. Safety Enclosures and Machine Guards

Essential safety applications:

- Equipment protection barriers

- Machine safety panels

- Perimeter fencing systems

- Operator safety shields

- Light curtain mounting frames

4. Material Handling Equipment

Key applications in material movement:

- Heavy-duty conveyor frames

- Parts transfer stations

- Storage system structures

- Lift-assist frameworks

- Guide rail systems

5. Clean Room Infrastructure

Critical for controlled environments:

- Wall frame systems

- Ceiling support structures

- Equipment mounting frames

- Filtration system supports

- Clean room partitions

6. Quality Control Stations

Essential for manufacturing precision:

- Inspection station frames

- Testing equipment supports

- Measurement system frameworks

- Calibration station structures

- Vision system mounting

7. Workstation Construction

Ergonomic solutions including:

- Adjustable bench frames

- Tool organization systems

- Monitor mounting solutions

- Equipment positioning frames

- Storage integration systems

8. Production Line Barriers

Organization and safety solutions:

- Line separation systems

- Modular divider frames

- Process isolation barriers

- Walk-through gates

- Guide rail mounting

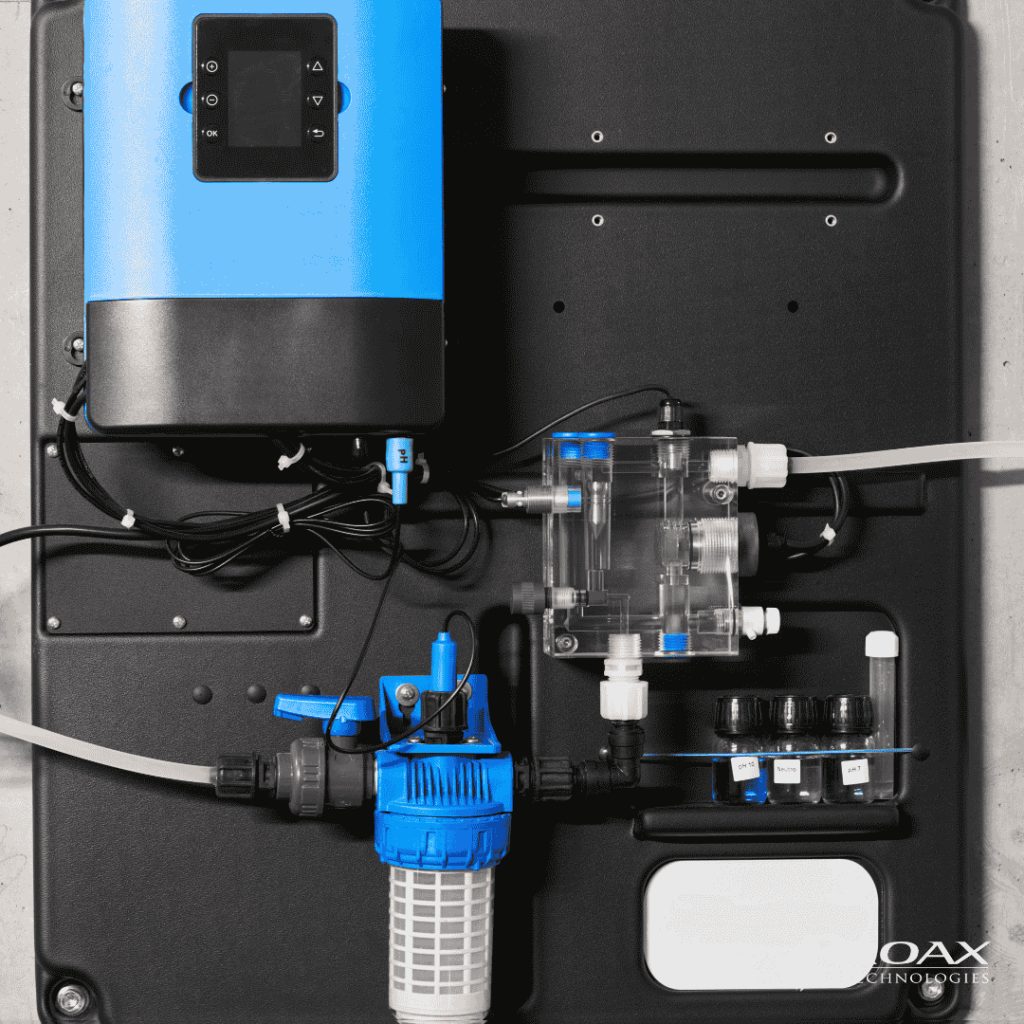

9. Equipment Mounting Systems

Versatile mounting applications:

- Control panel frames

- Machine mounting structures

- Sensor positioning systems

- Display mounting frames

- Power system enclosures

10. Custom Machine Frames

Specialized applications including:

- Custom equipment frames

- Special process enclosures

- Test system structures

- Prototype development frames

- Process-specific supports

Why These Applications Excel with Aluminum Extrusions

- Modular Design: Quick modifications and expansions

- Cost-Effective: Reduced installation and maintenance costs

- Versatile: Compatible with various mounting accessories

- Durable: Long-lasting performance in industrial environments

- Clean Appearance: Professional look for modern facilities

Selection Tips for Your Application

Consider these factors when choosing extrusions:

- Load requirements

- Environmental conditions

- Assembly method preferences

- Required accessories

- Future modification needs

Download Proax Technologies’ Aluminum Line Card

Related Story

Proax Technologies Becomes an Authorized Distributor of Captron

Proax Technologies is now an authorized distributor of Captron. High-quality, innovative sensor technology products are synonymous with Captron, also known as Captron Electronic GmbH, since 1983. We are a German company with locations in China, North America, and Poland, as well as sales partners in over 20 countries worldwide.

With a focus on expanding digital competencies and linking software with hardware, they develop an extensive range of capacitive and optical sensors as well as complete sensor systems.