Ontario Invests in Cutting-Edge Space and Robotics Technologies In Brampton

March 10, 2022

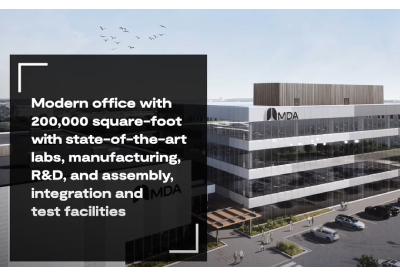

Ontario’s reputation as a North American leader in advanced manufacturing, research and development is growing with a new global headquarters and Space Robotics Centre of Excellence for Canadarm manufacturer MDA. With support from the Ontario government, MDA is investing $100 million over five years for its new Space Robotics Centre of Excellence and developing leading-edge technologies in commercial space robotics.

The new centre will be the home for the design, development, and manufacture of the iconic and industry leading Canadarm3. In addition, the company will create and sustain more than 700 long-term, high-skilled jobs at its Brampton headquarters in Ontario.The province is supporting this high-impact project with a $25 million investment to help ensure MDA’s world-leading technologies and innovation strengthen the province’s position as the home of Canada’s space industry.

“Ontario is home to the brightest talent and a thriving innovation ecosystem that make projects with incredible companies like MDA, a global leader in the space robotics industry, possible,” said Vic Fedeli, Minister of Economic Development, Job Creation and Trade. “Today’s investment will strengthen Ontario’s vibrant advanced technology sector, create exciting new jobs and ensure that scientific breakthroughs will continue to be made in our province.”

MDA’s new global headquarters in Brampton will ensure Ontario is the home for the development and construction of the Canadarm3, the next-generation space arm which will be a key part of the NASA-led Lunar Gateway program to establish a sustainable human presence on and around the moon. This project includes establishing a space robotics control centre in Ontario to operate space robotics missions for government and commercial customers.

This investment will combine MDA’s highly advanced space robotics capabilities with other advanced technologies such as automation and artificial intelligence. The funding will help stimulate over $1 billion in direct economic activity and anchor world-leading expertise in Ontario to support the province’s advanced robotics cluster. This investment will support the development of applications for robotic systems to support advanced manufacturing, mining, and medical technologies.

To assist promising technology startup companies, MDA will also continue its collaboration with Ontario-based industry, universities and colleges on space robotics and other technologies to ensure that Canada and the province remain leaders in space robotics and technologies.

“This new facility will be home to our growing highly-qualified team and will further unlock the potential of our world-class engineering and space mission expertise while allowing us to bring to market a full suite of innovative commercial space robotics products,” said Mike Greenley, Chief Executive Officer of MDA. “This assistance and the full backing of the Ontario government will allow us to grow and scale right here in Brampton and ensure we remain at the forefront of the global space economy.”

“Investing in innovation is key to Ontario’s economic growth, and with today’s announcement, Brampton is positioned to continue playing a leading role in the province’s high-tech and advanced manufacturing sectors,” said Prabmeet Sarkaria, President of the Treasury Board and MPP for Brampton South. “Our government is investing in technology today to build the Ontario of tomorrow—and made-in-Brampton innovation from leading-edge companies like MDA will be a major contributor to the growth of Ontario’s aerospace sector and beyond.”

Quick Facts

- •MDA’s modern 200,000 square-foot building will feature state-of-the-art labs, manufacturing, R&D, and assembly, integration and test facilities. The Centre of Excellence will also house a unique Space Robotics Mission Control Centre, enabling MDA to provide critical on-orbit operations capabilities to commercial and government customers worldwide.

- •Advanced technologies support the growth of companies across Ontario’s core sectors, including information and communications technology, financial services, cybersecurity, digital health, business services, logistics, retail technology, life sciences, environment, energy, aerospace and defence, transportation and advanced manufacturing.

- •Ontario’s space sector is the largest in Canada, accounting for 59 per cent of the industry based on revenues. In 2019, Ontario’s space sector directly employed almost 4,500 people, including more than 2,900 STEM jobs. This accounted for 44 per cent of Canada’s total space STEM workforce.

- •Ontario’s aerospace sector directly employs over 25,000 people and an additional 19,000 indirectly. Ontario is also home to 16 universities that offer engineering degrees and over 40 aerospace-related post-secondary programs. These include space science and space engineering programs at York University and Royal Military College of Canada, and space-focussed research institutes such as the University of Toronto Institute for Aerospace Studies and the Western University Institute for Earth and Space Exploration.

Additional Resources

Ontario Aerospace Industry overview