Sustainability At Festo – On the Way to Climate Neutrality

August 4, 2022

Automation is an enabler for the industrial transformation towards climate protection and resource efficiency, sustainability, and the circular economy. With its products and solutions, Festo contributes to enabling resource-efficient production and helps to establish a circular economy along the entire value chain – with the clear aim of reducing CO2 emissions.

Festo will massively reduce its carbon footprint over the next two years. “As a result, all of our production and logistics sites worldwide, as well as the German sales locations and the corporate headquarters in Esslingen, will be CO2-neutral from the beginning of 2023,” explained Festo CEO Dipl.-Ing. Dr. h.c. Oliver Jung at the international press conference of Festo in Esslingen.

Sustainability Strategy and Sustainability Report

Festo has aligned its own Sustainability Strategy along the Strategic Development Goals (SDGs) of the United Nations. Scope 3 emissions will play an increasingly important role in this. Here, emissions from purchasing and logistics are considered on the one hand, and the use of products by customers on the other. In the annual Sustainability Report, Festo documents its global responsibility with numerous examples and provides information about its sustainable corporate development. Their current Sustainability Report is available on their website (see link).

The “Blue World” approach

Festo contributes to global sustainability in many places and visualizes this in the “Blue World”. “With this, we want to express how automation technology can balance the supply of the world’s population on the one hand and the protection of our natural resources and climate-neutral production on the other,” explains Oliver Jung. The Blue World illustrates how Festo is striving to transform industrial production into an efficient and more climate-friendly way of manufacturing. The technology equator stands for the current and future technology fields.

Innovations as the key to more sustainability

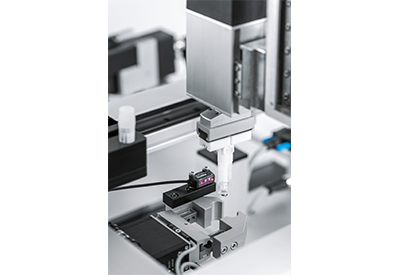

“Our customers increasingly perceive us as a partner in this process. Together with us, they can drive the transformation of the industry. Innovations are the key here,” says Oliver Jung. Festo has made great strides in important innovations, such as digital and intelligent pneumatics, automation platforms and concepts for saving energy in pneumatics. Festo also presented the world’s first pneumatic cobot at this year’s Hannover Messe. Festo has invested around 7% in research and development in 2021.

Learning as an essential element of sustainable development

As a solution provider for technical education and training, Festo Didactic imparts skills and abilities to master the challenges of the present and shape the future for the benefit of future generations. Festo also attaches great importance to strong training and further education within its own company. In addition, Festo Didactic develops learning content and learning environments for new training professions, based on the increasing requirements in the areas of IT, AI, data science or sustainability.

The transition to a circular economy

Festo sees the next development push for industrial production in the change towards a consistent circular economy. This change holds enormous growth potential and at the same time preserves the natural foundations of life for future generations. “In nature, there is no waste and no wastage, we just have to learn to transfer these principles to our economic activity. That is why we are working on transferring these principles to automation as part of our Bionic Learning Network with the “PhotoBionicCell” project,” says Oliver Jung.