Siemens Empowers Future Workforce with New Industry Credential

June 4, 2025

- Siemens develops new ‘Expedite – Skills for Industry’ credential to empower jobseekers to differentiate their engineering skillset as they enter the workforce

- New credential helps hiring managers and talent acquisition teams prioritize candidates with specific competencies

Siemens Digital Industries Software announced on June 2 its ‘Expedite – Skills for Industry’ credential, a four-course, fully online microcredential which prepares students for industry by connecting engineering theory with practical skills. The new credential covers key trends, business processes and tech-based work environments, providing an essential foundation in industry-relevant skills and empowering graduates to confidently enter the workforce equipped to meet the future demands.

“Our new credential addresses the shift in the talent acquisition that now increasingly relies on skills-based hiring practices, seeking out and preferring candidates who can demonstrate and apply engineering proficiencies and durable skills to complement formal degree programs,” said Dora Smith, Senior Director, Future Workforce and Academic Strategy, Siemens Digital Industries Software. “Microcredentials are compressed courses of study that demonstrate proven skills and culminate in a verifiable digital badge. They not only give jobseekers the opportunity to differentiate themselves in a highly competitive landscape but also aid employers in prioritizing candidates with the specific competencies they need.”

Developed by Siemens, the ’Expedite – Skills for Industry’ credential is a four-course microcredential designed for engineering students and early-career engineers seeking to complement their formal education through the development of in-demand industrial knowledge and professional skills – delivered via the global Coursera learning ecosystem.

The new credential enables learners to connect the theory they’ve gained in the classroom with real-world knowledge focused on product lifecycle management and trending applications of AI, the digital twin, sustainable engineering and the internet of things. Additionally, the credential introduces and strengthens critical workplace capacities such as collaboration, project management, business processes and solutions and risk management. Once a learner completes ‘Expedite – Skills for Industry’, they’re awarded a verifiable digital badge that can be displayed within their portfolio and on social media to attract recruiters and inform hiring managers.

“Piloting this Siemens credential provides our students with an additional layer of validity and credibility. When potential employers read the credentials on a resume or see the badge posted, they see Siemens as a clear indicator of quality,” said Craig Downing, Associate Dean of Lifelong Learning, Rose-Hulman Institute of Technology. “I am always on the hunt for educational opportunities or professional opportunities to help our students see how the discipline of engineering is practiced in the real world. While we teach the theoretical, there is a transition between how those theories are exercised in practice. Credentials, such as ‘Expedite – Skills for Industry’, not only boost students’ real-world knowledge but also increase their marketability, showcasing their competence in the fields directly impacted by their degree and giving future employers greater confidence in their hiring decisions.”

The ‘Expedite – Skills for Industry’ credential will be available later this summer and follows the recent news that Siemens has also completed the first part of its collaboration with ABET to pilot recognition of industry credentials – beginning with its ‘Design for the Circular Economy (Sustainable Operations pathway)’ credential which has been recognized by ABET under its Certificate Recognition Standards.

To learn more about Siemens’ work at the forefront of workforce development, empowering its global ecosystem of learners with internationally respected qualifications that will shape the next generation of digital engineering talent, visit: https://www.sw.siemens.com/en-US/academic/credentials/

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries. Siemens Digital Industries Software – Accelerating transformation.

Note: A list of relevant Siemens trademarks can be found here. Other trademarks belong to their respective owners.

Related Story

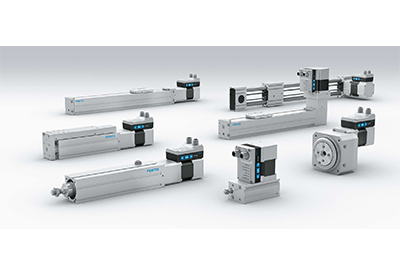

Siemens Launches Next-Generation Motion Control System for Basic Automation Applications

At this year’s AUTOMATE, Siemens announced the launch of its enhanced motion control portfolio, featuring SINAMICS servo-drive systems and the new SIMATIC S7-1200 G2 controller, delivering unprecedented performance and flexibility for basic automation applications including handling, moving, positioning and processing.

The new solution combines three key innovations:

- Advanced SINAMICS S200 and S210 servo-drive systems

- New SIMATIC S7-1200 G2 controller

- Compatible SIMOTICS servomotors