Integrated Lifecycle Management for Electronics

June 14, 2023

Focus on digital collaboration to boost innovation and realize these benefits of integrated lifecycle management for electronics:

- Connect people and processes across the entire product ecosystem

- Teams work in parallel but with full visibility to design products faster

- Collaboration with partners and suppliers for faster NPI

- Gain the flexibility to adapt quickly to future product needs

More Information

Integrated Lifecycle Management

Related Story

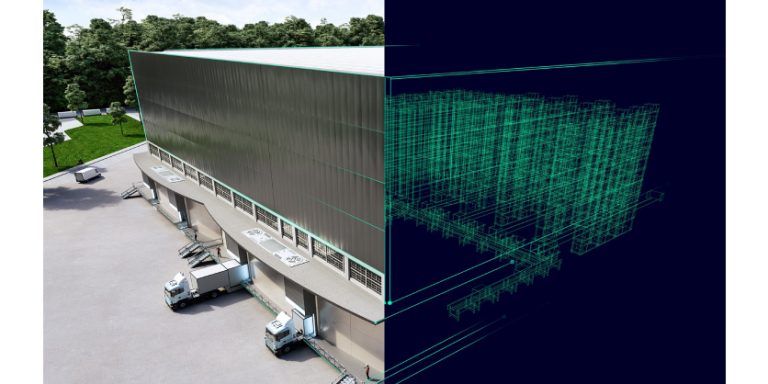

Maximum Transparency: Siemens Shows the Holistic Digital Twin of a Logistics Center at LogiMAT 2023

Under the motto “Intelligent intralogistics – experience the flow”, Siemens is presenting the holistic digital twin of a real logistics center at this year’s Logimat. The logistics and intralogistics industry finds itself in a rapidly changing and demanding environment: increasing demand for energy efficiency and sustainability, the shortage of labor, and cybersecurity threats are just some of these challenges. With an extensive automation and digitalization portfolio along the entire value chain specifically for the intralogistics industry, Siemens supports machine builders and warehouse operators in overcoming these challenges.