Highly Dynamical XPlanar Mover from Beckhoff Automation

February 15, 2024

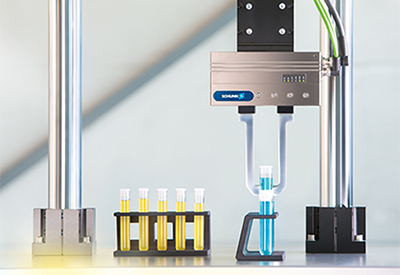

The XPlanar mover is the magnetically floating, freely movable, and wireless component of the XPlanar system. Each individual mover can be moved highly dynamically without collisions and positioned freely on the system. Also lifting, lowering, weighing, tilting or rotating while travelling is possible.

The intelligent transport system combines the advantages of conventional systems and supplements them with a unique magnetic levitation technology. With its floating 2D product transport, the planar motor system opens up a whole host of new possibilities.

More Information

Related Story

Beckhoff to Showcase Cabinetless Machine Control, Adaptive Automation, XPlanar, and New Vision at ADM Toronto 2023

Based on flexible and scalable PC-based automation, MX-System, XPlanar, machine vision, and other innovations help empower Canadian leaders in packaging, food and beverage processing, pharma, and beyond

At Advanced Design & Manufacturing Expo (ADM) Toronto 2023, Beckhoff showcased Canadian market leaders in packaging, food and beverage processing, pharma and beyond how to automate what’s next. Visitors to Beckhoff booth #1205 discovered many revolutionary solutions in intelligent motion control and mechatronics as well as a wide range of Industrial PC (IPC), EtherCAT I/O, drive technology, vision, and more. One such solution is their intelligent transport system.

New concepts require dynamic motion, flexibility and scalability in production as well as automated transport between process stations. The XPlanar and XTS adaptive automation systems deliver competitive advantages in these applications. XPlanar replaces many functions of traditional material handling systems and robots with magnetically levitating movers, which offer zero friction, automatic collision avoidance, path planning, 360-degree rotation and zero wear on the system. The modular XTS propels movers with high dynamics, eliminates mechanical components and performs changeovers instantly via standard TwinCAT 3 automation software. Both improve uptime and the ROI equation, providing significant competitive advantages for wide-ranging industry applications.