ABB Opens New $100 Million Campus in Wisconsin

October 31, 2024

- Facility to support future growth in ABB’s largest market with production of electric drive technology used in variety of industries

- New manufacturing and customer experience facility features technology to help ABB meet its sustainability goals

- Geothermal heating and modern HVAC systems will allow ABB to recycle wasted heat, eliminate the use of natural gas and reduce energy usage by more than 45%

ABB has began the phased opening of a new $100 million campus in New Berlin, Wisconsin to increase U.S. production capacity of industrial electric drives and service to fully meet Build America Buy America Act (BABAA) requirements. ABB employees, elected officials, education leaders, and media gathered for a ribbon cutting event to mark the first phase opening of the campus.

“ABB is a technology leader in electrification and automation and the U.S. market is an important growth engine for our business,” said Brandon Spencer, President of ABB’s Motion Business Area. “Investment in this modern manufacturing facility gives ABB access to a highly qualified workforce, strengthens localized supply chains, and keeps us close to our customers.”

The need to reduce and avoid emissions is driving strong demand for ABB’s electrification and automation solutions in the power, industrial, transport and building sectors. ABB empowers customers across the globe to optimize, electrify and decarbonize their operations.

“ABB is strengthening America’s infrastructure and introducing new, cleaner technologies to help customers boost competitiveness while lowering their carbon footprint,” said Tuomo Hoysniemi, President of ABB’s U.S. Motion Business Area and Global Drive Products Division. “We are also using technology to run our own factory cleaner with building design features such as solar power, geothermal heat pump and modern HVAC systems, and advanced building controls. The innovations will help ABB meet its own 2030 sustainability goals.”

While the increased footprint of the new facility will better serve ABB’s future growth in the company’s largest market, the highly automated production facility will be complemented by a digital Customer Experience Center and a state-of-the-art Innovation Lab to better serve customers in the United States. By locating a warehouse distribution center on the campus, ABB will reduce transportation costs and associated emissions.

The new campus will welcome more than 700 ABB employees and is expected to add an additional 100 new jobs over the next three years.

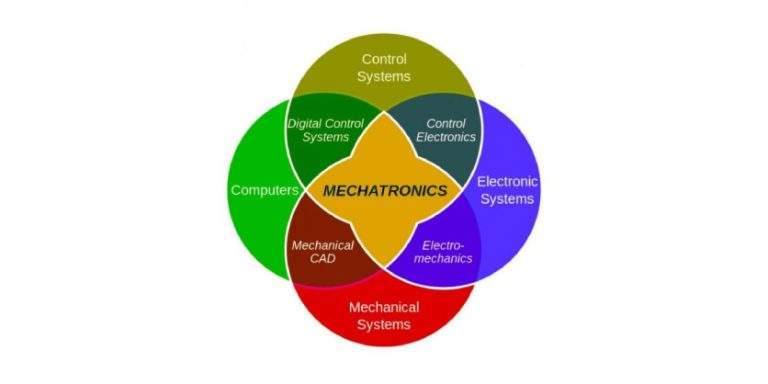

“It is important for business, government and educational institutions to work together to prepare the workforce for modern manufacturing,” said Kelly Kling, Drives Site Leader and Head of Finance for US ABB Motion Business. “STEM education will better prepare the nation for the high demand of electrical and mechanical engineers, contractors and automation technicians. It is important for ABB, our customers, and will build a stronger America.”

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

Related Story

ABB Opens Refitted, State-Of-The-Art US Robotics Facility, Reaffirming Commitment to North American Customers

ABB has opened its refitted US robotics headquarters and manufacturing facility in Auburn Hills, Michigan, which will support ABB Robotics’ global leadership in developing and manufacturing cutting-edge robotic solutions in the US, for the US and the Americas. The expanded facility reflects ABB’s commitment to long-term growth in the US market, which is predicted to follow global growth rates for robotics of 8% CAGR*, as well as the company’s global investment to build Robotics and Automation capacity and create new, highly skilled jobs.

This is ABB’s third global robotics factory expansion in three years across China, Europe and the Americas and is part of its efforts to further strengthen its local-for-local footprint.