ABB Exclusive Webinar – March 2, 2022

February 17, 2022

January 19, 2024 Wednesday, January 24, 2024 2:00 PM – 3:00 PM EST Join Rittal on January 24th to discover how their Automation Systems can supercharge your workflow—making it smarter and faster! At Rittal, they offer a spectrum of solutions, from manual tools to fully automated machine technology, designed to enhance productivity. Here’s a glimpse…

July 17, 2025 PrecisionX Group (“PrecisionX”), a portfolio company of CORE Industrial Partners (“CORE”), has announced the acquisition of Florida-based Hudson Technologies (Hudson), a manufacturer of mission-critical deep drawn metal components. The acquisition strengthens PrecisionX’s position as a U.S.-based provider of high-reliability metal components in the aerospace & defense, medical device, satellite & space, and…

April 18, 2024 Expansion projects by four companies will create 153 new, local jobs The Ontario government is supporting $125 million in investments by four companies to expand local manufacturing capacity in the automotive and food processing sectors while creating 153 new jobs in Windsor and Leamington. This includes a $60 million investment from DS…

July 21, 2025 Recently, the Honourable Darren Fisher, Member of Parliament for Dartmouth—Cole Harbour, on behalf of the Honourable Gary Anandasangaree, Minister of Public Safety, along with senior officials from the Canada Border Services Agency (CBSA), the Halifax Port Authority and the Africville community, celebrated the opening of the new Marine Container Examination Facility (MCEF) in…

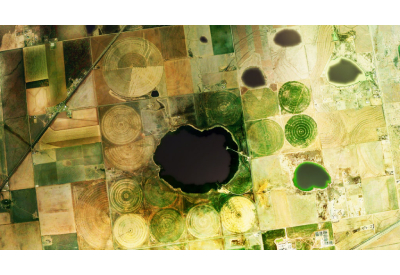

Recently, at the 2022 PrecisionAg VISION Conference, EarthDaily Analytics Corp, a vertically-integrated data processing and analytics company pairing cutting-edge Big Data tools with proven Space technologies, announced the rebranding of its Geosys division to EarthDaily Agro. The Company also announced the launch of a new, next-generation software platform offering best-in-class agricultural analytics service with unmatched reach, speed, quality and integration capabilities.

The road to success for Markham-based artificial intelligence (AI) solutions scale-up EAIGLE began in perhaps the least techy place imaginable: public swimming pools. Health and safety protocols dictate that water in city pools must be changed based on how many people swim each day. But according to EAIGLE Co-Founder and CEO Amir Hoss, many litres of water are typically wasted every day, which has a drastic impact on our environment. With his experience working on smart cities, Hoss teamed up with University of Toronto PhD graduate and current EAIGLE Co-founder and CTO Mahdi Marsousi to develop a way to count the number of people who visit the pool using an image processing software powered by deep tech AI.

December 18, 2025 Questions created by Krystie Johnston, Managing Editor at Kerrwil Media Ltd. Answers to be attributed to Nick Rinaldi, Director of Business Development – Home Builders, Schneider Electric Canada Canada’s housing market is demanding smarter, more sustainable solutions, and Schneider Electric Canada is helping to lead this transformation. Their innovative residential technologies make homes more energy Read More…

December 18, 2025 By Krystie Johnston There is something special about having a passion and putting it to work for a good reason. And that is exactly what STUDSON and HighBar are doing right now with the recent launch of their HighBar-equipped SHK-1 industrial helmet. A revolution in head safety, the concept version was introduced just last year Read More…

In today’s fast-paced manufacturing and logistics industries, the need for efficient and flexible material movement solutions has never been greater. Traditional methods like conveyor systems, forklifts, and manual pushcarts have served us well, but they come with limitations.

That’s why Omron is thrilled to announce the launch of their game-changing MD Series of Autonomous Mobile Robots (AMRs). Read more

December 15, 2025 Festo’s new CMMT-AS-S3 servo drive series enables machine builders to achieve higher levels of functional safety while simplifying design, wiring, and certification. The CMMT-AS servo drives give OEMs a choice between two distinct safety levels – Basic (S1) and the new Advanced (S3) – offering a flexible, cost-effective way to meet safety Read More…

December 12, 2025 Schneider Electric, a global energy technology leader, announced the availability of its One Digital Grid Platform, a unified, artificial intelligence AI-enabled software platform designed to help utilities modernize faster, strengthen grid resilience and reduce energy costs. The platform was launched simultaneously in Spain at Enlit Europe, attended by more than 15,000 professionals from Read More…