A Milestone in Connectivity – Made in Germany

August 19, 2025

Electrical and connectivity company Weidmüller, which is celebrating its 175th birthday this year, has been manufacturing W-Series screw-type terminal blocks for more than 40 years

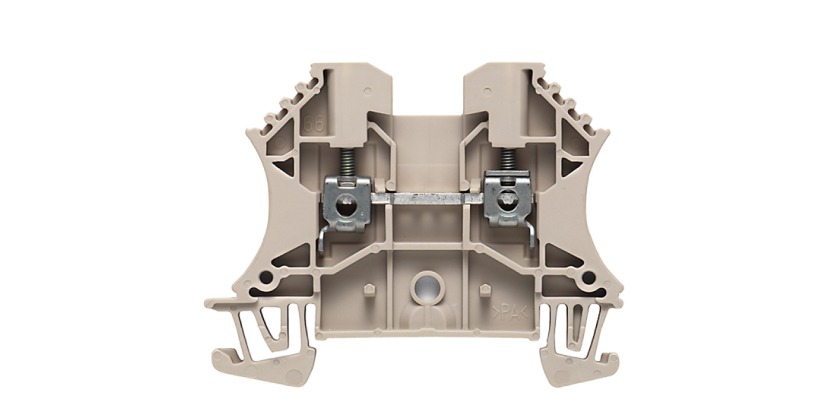

Weidmüller, a leading provider of industrial connectivity and inventor of the plastic-based terminal block, is looking forward to two major milestones: celebrating 175 years of company history, and 40 years of the W terminal block family. Since it was invented, the W-Series has been setting standards in electrical connectivity with its design and quality. Screw-type terminals from Weidmüller are considered synonymous with durability and reliability, and help ensure more efficient and safe electrical connections worldwide.

A symbol of quality and reliability, for over 40 years

In the early 1980s, Weidmüller chose to take a pioneering step and completely redesigned its screw-type terminal product line. The company did so with the goal of thoroughly optimising not only the line’s technical properties, but also its design and operating convenience. Weidmüller wanted to ensure they could well exceed modern requirements – which is why the line is still considered a standard today. The result of this new development are clearly structured functional areas, as well as an ergonomically sophisticated shape that makes it significantly easier to grip and install the terminals.

The ergonomic contour is precisely designed to adapt to natural finger positioning and ensure optimal and efficient handling. This forward-thinking shape set a new standard, and is still used today worldwide in countless terminal blocks with screw connection technology. The W-Series quickly became established as a reliable and widely used connectivity element. Billions of W-Series terminals have been sold – evidence of their outstanding performance and global popularity. As a top-selling terminal block, for example, the WDU 2.5 meets the highest standards for resistance, quality, and reliability, and is considered a standard in industry today.

“This success is proof of Weidmüller’s longevity and force of innovation. W-Series terminal blocks stand for decades of experience in connectivity, and meet the strictest requirements for performance and safety, which are essential in global applications” says Jörg Diekmann, Team Leader Product Modification at Weidmüller.

A growing holistic concept that sets market standards

In close collaboration with users, Weidmüller has developed an impressive variety of over 1,000 colour and product variants over the decades. This extensive product family is today considered one of the most comprehensive and high-performing available on the market. Weidmüller’s screw terminals impress with their consistent system design, which both simplifies installation and offers a high level of flexibility.

One unique feature is the uniform design of through-terminals for rated cross-sections of 2.5 mm² to 10 mm², which reflect the systematic concept of the product line. Supplemented by an extensive, uniform range of accessories, the product family can be used in many different contexts and is suitable for countless industrial applications. “Even after more than 40 years of continuous development, we are not resting on our laurels” assures Karlo Stjepanovic, Head of Development Terminals at Weidmüller. The company’s latest products include the introduction of a Marshalling product group specially developed for the process industry, underscoring Weidmüller’s commitment to innovation.

Related Story

Weidmüller Achieves Nearly One Billion Euros in Sales Despite Challenging Market Conditions

Following exceptionally strong growth in 2021 and 2022, the electrical connectivity and automation specialist Weidmüller has experienced a decline in sales for the second consecutive year. In 2024, revenue fell by approximately 11 percent compared to the previous year, reaching EUR 980 million. The decline in sales is attributed to a weak economy. “Given the challenging market conditions, we had to accept a drop in revenue. Last year’s result fell short of our expectations – the market correction following the growth trajectory proved more persistent than we had anticipated,” says Dr Sebastian Durst, CEO of the Weidmüller Group, headquartered in Detmold.